High pressure food processing system

Achieve extended shelf life and enhanced food safety with a cutting-edge high-pressure processing solution, ideal for preserving natural taste and nutritional value in a wide array of liquid and semi-solid products.

Processes and Preserves Products via High Pressure

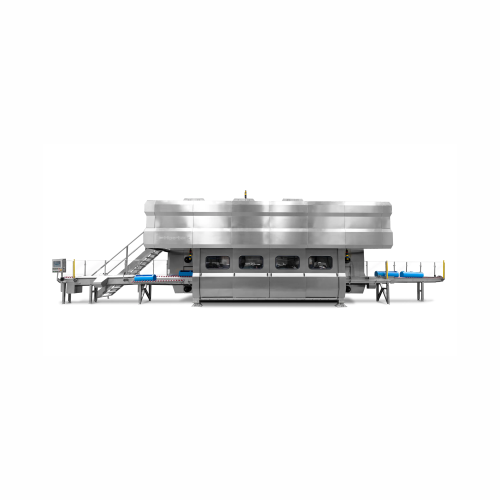

The Hiperbaric 300 from Hiperbaric is an industrial high pressure processing system designed to elevate product safety and extend shelf life across industries including food, beverage, and cosmetics. Employing high pressure technology, it processes a wide range of products—such as cold-pressed juices, ready-to-eat meals, and anti-aging creams—without compromising quality. With a processing capacity of approximately 1,350 kg/h, the system supports medium to high production volumes. Its design allows for flexibility with standard or integrated configurations, enabling easy integration into existing production lines. The Hiperbaric 300 is constructed with durable materials, featuring an optimally designed 300 mm vessel diameter for economic competitiveness. It operates efficiently with expandability options for future production growth, ensuring it adapts to your scaling needs. The equipment adheres to industry standards for safety and quality, making it a sound choice for manufacturers committed to innovation and reliability.

Benefits

- Enhances product safety and shelf life without heat, preserving natural flavors and nutrients.

- Supports scalable operations with expandable configuration options for future growth.

- Reduces operational costs with energy-efficient design and minimal maintenance needs.

- Integrates seamlessly into existing production lines with standard or integrated configuration options.

- Complies with international safety and quality standards, ensuring regulatory assurance.

- Applications

- Beverages, Meat products, Pet food, Plant based and fruit products, Ready-to-eat (rte) meals, Guacamole and avocado products, Seafood products, Cosmetics, Pharma, Baby food and fruit purees, Juices, Salsas, Dairy products

- End products

- Vitamin c serum, Apple puree, Organic almond milk, Ready-to-eat chicken breast, Greek yogurt, Anti-aging face cream, Tomato salsa, Avocado hummus, Smoked salmon, Vegan protein shake, Grain-free dog food, Pre-packaged quinoa salad, Cold-pressed orange juice

- Steps before

- Product Loading, Filling Efficiency Optimization

- Steps after

- Product Unloading, Packing, Shelf Life Extension

- Input ingredients

- juices, beverages, guacamole, avocado products, meat products, seafood products, salsas, plant-based products, fruit products, baby food, fruit purees, ready-to-eat meals, dairy products, pet food, pharma products, cosmetics

- Output ingredients

- processed juices, processed beverages, shelf-stable guacamole, shelf-stable avocado products, safe meat products, safe seafood products, preserved salsas, preserved plant-based products, preserved fruit products, extended shelf life baby food, extended shelf life fruit purees, ready-to-eat meals with extended shelf life, longer-lasting dairy products, preserved pet food, safe pharma products, preserved cosmetics

- Market info

- Hiperbaric is renowned for its expertise in high-pressure processing (HPP) equipment, offering innovative solutions for food safety and shelf-life extension. The company is recognized for technological innovation, reliability, and strong customer support in the industrial equipment market.

- Throughput

- 1, 410 kg/hour (3, 100 pounds/hour)

- Vessel Capacity

- 300 liters (79.3 US liquid gallons)

- Vessel Diameter Inside

- 300 mm (11.8 inches)

- Equipment Dimensions

- L

- Production Capacity

- Approximately 1, 350 kg/h (2, 976 lbs/h)

- Pressure Rise Time

- Up to 600 MPa (87, 000 psi)

- Hold Time

- 3 minutes

- Electrical Frequency

- 60 Hz

- Operation Type

- Batch

- Automation level

- Standard / Integrated

- Energy efficiency

- Lowest production cost

- Changeover time

- Expandable configuration

- Cleaning method

- CIP capable

- Pressure rise time

- 600 MPa / 87, 000 psi

- Pressure holding time

- 3 minutes

- Biological compatibility

- High Pressure Processing is known for its non-thermal, clean nature which is favorable for biological compatibility

- Cleanability

- Easy to clean

- HPP systems typically facilitate thorough cleaning and maintenance

- Corrosive resistance (e.g. acids)

- HPP equipment is usually made of stainless steel, which offers resistance to corrosion

- Density/particle size

- Handles various densities and particle sizes in food products

- HPP cycle duration

- Includes product loading/unloading, pressure rise, and pressure release

- Production Cost

- Lowest in the market

- Footprint

- Compact

- Configuration

- Standard or Integrated

- Expandability

- Expandable Configuration for Future Growth

- Configuration

- Standard (floor) / Integrated (above)

- Expandable Configuration

- Yes, for future growth

- Geometry Optimization

- 300 mm diameter

- Production Cost

- Lowest in market