Aseptic processing equipment for food products

Optimize aseptic processing to ensure microbiological stability and product integrity in your liquid food production line, from initial sterilization to precise aseptic filling, with specialized equipment designed for efficiency and versatility.

Transfers and Seals Sterile Liquid Products

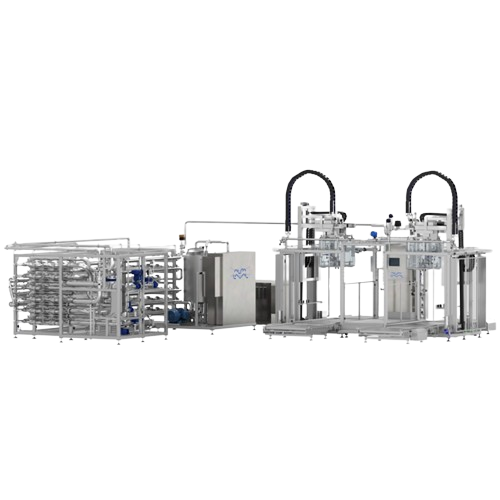

The Compact Aseptic Filler from Alfa Laval is designed to address the stringent requirements of aseptic packaging in the food and beverage industry. It ensures microbial sterility by transferring liquid food products and beverages into pre-sterilized packaging under aseptic conditions. The unit offers a seamless integration into continuous production lines and supports a variety of applications, including fruit juices, dairy drinks, and plant-based milks.

Ideal for use in high-demand environments like food manufacturing and beverage production, this filler accommodates a range of bag sizes, from 3 to 1000 liters, tailored to suit bulk processing for hotels, restaurants, and catering services. Its PLC-controlled system allows operators to adjust parameters for precise filling and quick changeovers, enhancing throughput and minimizing downtime.

The Compact Aseptic Filler’s energy-efficient design reduces environmental footprint, utilizing optimized controls that lower energy consumption. Made from durable stainless steel, it provides excellent corrosion resistance, ensuring longevity in rigorous operating conditions. Additionally, it features a CIP (Cleaning-In-Place) system for rigorous, contamination-free cleaning to maintain the highest level of hygiene.

Alfa Laval provides comprehensive engineering support and customization options, enabling you to tailor the system to your specific production needs, ensuring it fits seamlessly within your existing operations.

Benefits

- Ensures product sterility and extends shelf life with reliable aseptic filling.

- Increases production flexibility and efficiency with quick changeovers and automated controls.

- Lowers energy consumption and environmental impact with optimized operation.

- Minimizes contamination risk and maintenance effort with integrated CIP system.

- Accommodates diverse packaging requirements, from small to bulk sizes, for versatile application.

- Applications

- Beverages, Fruit products, Low-acid food products, Liquid food products, Vegetable products, Dairy products, High-acid food products

- End products

- Ready-to-drink iced tea, Ketchup, Uht milk, Tomato puree, Greek yogurt, Broccoli soup, Salsa, Applesauce, Liquid plant-based milk, Fruit juices

- Steps before

- Purification, Emulsification

- Steps after

- Sterilization, Filling, Packing

- Input ingredients

- fruit feedstocks, vegetable feedstocks, liquid food products, viscous food products, high-acid food products, low-acid food products, dairy products, beverages

- Output ingredients

- commercially sterile food products, hermetically sealed packaging, shelf-stable products, bag-in-box packaging, industrial drums, totes, bins, preserved taste and nutrients

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Capacity

- 3–20 litres, 200–1000 litres

- Filling accuracy

- High accuracy

- Filling speed

- High speed

- Automation

- Automated software programmes

- Product treatment

- Gentle

- Processing flexibility

- Adjust capacity, adapt recipes

- Sterilization method

- UHT (Ultra High Temperature) processing

- Cooling option

- Ultra high temperature processing

- Working mechanism

- Aseptic processing

- Integrated steps

- Sterilization, cooling, aseptic filling

- CIP/SIP

- CIP 121°C / SIP 135°C

- Automation level

- Automated software programmes

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Fast changeover between production runs

- Cleaning method

- Optimized cleaning cycles

- Energy efficiency

- Proven, energy-efficient

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Bag sizes

- 3-20 litres to 200-1000 litres

- Tank shape

- Modular aseptic tank

- Feed/Discharge method

- Pre-sterilized packaging

- Control panel type

- Programmable Logic Controller (PLC)

- Integration possibilities

- Automated software programmes

- Bag size options

- 3-20 litres to 200-1000 litres