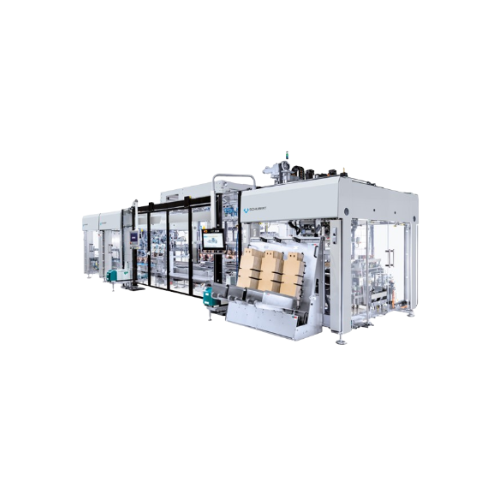

Flexible packaging system for beverage containers

Streamline your packaging process with a modular system that adapts seamlessly to diverse container types, enhancing efficiency and reducing operational downtime.

Configures and Packs Bottles and Cans Efficiently

The Innopack TLM by KHS Group is a modular packaging system designed for high flexibility and efficiency in handling various packaging needs across the beverage, food, and non-food industries. This system excels in packing and unpacking operations for an array of containers, including PET bottles, cans, and glass bottles. With its modular configuration, the Innopack TLM can process up to 86,400 containers per hour, offering quick format changeovers without the need for fine adjustments, facilitating seamless adaptation to different packaging formats such as clusters and trays.

Integrating seamlessly into existing production lines, its blocked design minimizes space while reducing maintenance, energy consumption, and operational costs. The system’s robot technology ensures precision, reducing reject quantities and maintaining product quality from the first pack. Available with PLC controls, the Innopack TLM supports automation with remote monitoring capabilities for enhanced operational oversight. Additionally, its engineering support and customizable options allow for adaptation to specific production requirements, making it an integral part of a sustainable and efficient packaging process.

Benefits

- Enhances operational efficiency with rapid format changeovers, reducing downtime.

- Minimizes space requirements by integrating multiple functions into a single compact block.

- Lowers energy consumption and maintenance costs with advanced robot technology.

- Boosts product quality with precise packing and low reject rates.

- Adapts to evolving packaging trends with its flexible, modular design.

- Applications

- Food, Liquid food, Pet bottles, Wine, Milk, Non-food, Iced tea, Spirits, Still water, Cans, Homecare products, Juice, Soft drinks, Beverage products, Beer, Sparkling wine, Glass bottles

- End products

- Iced tea bottles, Bottled mineral water, Champagne bottles, Soda cans, Pet bottled cola, Vodka bottles, Processed canned vegetables, Pasteurized milk cartons, Fruit-flavored water bottles, Orange juice bottles, Glass bottled spring water, Canned beer, Liquid soap bottles, Carbonated soft drinks, Red wine bottles, Detergent bottles

- Steps before

- Container design, Syrup preparation, Sugar dissolving, System planning

- Steps after

- Packing, Labeling, Storage, Distribution

- Input ingredients

- cans, glass bottles, PET bottles, beverage products, food products, non-food products

- Output ingredients

- flexible primary packaging, secondary packaging, clusters, baskets, top-clip, fully enclosed wrap, semi-open wrap, trays, folding cartons, plastic crates

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Packaging Capacity

- up to 86, 400 containers per hour

- Automation

- Modular block system

- Format Changeover

- Quick, tool-free

- Primary Packaging Styles

- Clusters, baskets, top-clip, fully enclosed, semi-open wrap

- Secondary Packaging

- Trays, folding cartons, plastic crates

- Modular Design

- Yes

- Operator Requirement

- Operated by just one operator

- Energy Consumption

- Reduced

- Reproduction during Changeovers

- High reproducibility

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Glass / PET / Cans

- System configuration

- Modular

- Footprint

- Compact/space-saving

- Discharge method

- Block Setup

- Packaging options

- Clusters, baskets, top-clip, fully enclosed, semi-open wrap, trays, folding cartons, plastic crates

- Control panel type

- PLC-controlled

- Modular design

- Yes/No

- Integration possibilities

- Block setup

- Format changeover compatibility

- Tool-free