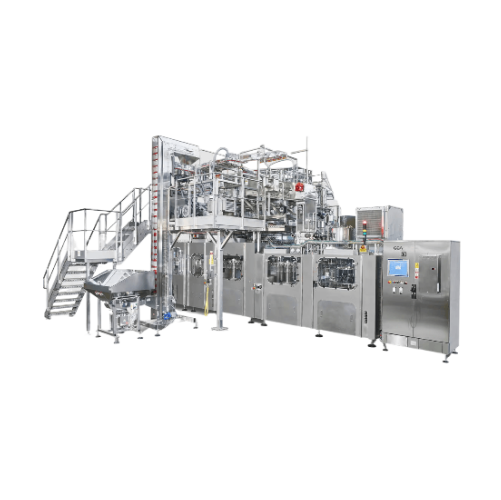

Aseptic filling system for milk-based drinks

Ensure sterile bottling of milk-based and sensitive beverages with this system, offering a highly efficient hydrogen peroxide-based sterilization, crucial for preserving product shelf-life without water rinsing.

Sterilizes, Bottles, and Caps Liquid Products

The Whitebloc Aseptic Filling System from GEA is engineered to address the rigorous demands of aseptic bottling for dairy and beverage industries. This system stands out for its hydrogen peroxide (H2O2)-based sterilization technology, providing an efficient solution for preserving the shelf life of sensitive beverages like UHT milk, plant-based milk, and probiotic drinks. It processes up to 48,000 bottles per hour, integrating seamlessly into high-speed production lines with automatic bottle changeover and minimal downtime.

Featuring PLC control and real-time monitoring, the system guarantees sterilization efficiency through its ‘Smart Sensor’ technology, which ensures precise treatment of every bottle. Designed for versatility, it handles both HDPE and PET containers, compatible with varied bottle and cap types. By eliminating the need for water rinsing, it achieves water conservation while maintaining up to 6 log bacteria reduction. The incorporation of VHP (Vaporized Hydrogen Peroxide) for cap and foil sterilization furthers its comprehensive sterilization capabilities. The system is enclosed in a microbiological isolator that maintains hygiene with sterile air overpressure to prevent contamination, ensuring ease of cleaning and maintenance while supporting customization and engineering support tailored to specific production needs.

Benefits

- Enhances production flexibility with automatic bottle changeover and handling of multiple cap styles.

- Conserves water by eliminating the need for post-sterilization rinsing.

- Maintains high hygiene standards with an isolated microbiological zone and sterile air overpressure.

- Extends operational time without cleaning cycles, offering up to 165 hours of continuous production.

- Ensures precise sterilization with real-time monitoring to meet stringent microbial reduction requirements.

- Applications

- Beverages, Milk-based drinks, Sensitive beverages, Low acid products, High acid products, Dairy products

- End products

- Vegetable juices, Milkshakes, Uht milk, Bottled water, Oat milk, Almond milk, Probiotic drinks, Soy milk, Fortified vitamin drinks, Iced tea, Electrolyte drinks, Flavored milk beverages, Fruit juices

- Steps before

- Bottle Blowing, Air Conveying

- Steps after

- Filling, Capping, Packaging, Labeling

- Input ingredients

- HDPE bottles, PET bottles, H2O2 solution, caps, aluminium foil closures

- Output ingredients

- aseptically filled HDPE bottles, aseptically filled PET bottles, sterilized caps, sterilized aluminium foil closures

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Sterilization Technology

- H2O2-based sterilization

- Sterilization Efficiency

- Up to 6 log reduction

- Production Speed

- Up to 48, 000 bottles/hour

- Line Availability

- 165 hours without intermediate cycles

- Residual Peroxide Level

- Less than 0.5 ppm

- Container Type Compatibility

- HDPE and PET

- Cap Compatibility

- Flat cap / Sports cap / Aluminum foil closures

- Changeover Type

- Automatic bottle changeover

- Cap Sterilization Technology

- VHP-based

- Temperature Holding System

- Dedicated system positioned between blower and treatment carrousel

- Microbiological Isolator Type

- Enclosed, with sterile air overpressure

- Sterilization Technology

- H2O2-based

- Automation Level

- PLC-controlled

- Changeover Time

- Automatic bottle changeover

- Bottle Handling Configuration

- Standalone or integrated with blowing machine

- Sterilization Efficiency

- Less than 0.5 ppm residual peroxide

- Biological compatibility

- Yes

- Cleanability

- Easy to clean surfaces

- Corrosive resistance (e.g. acids)

- H2O2 resistant

- Density/particle size

- Suitable for PET and HDPE bottles

- Temperature compatibility

- Withstands heat during sterilization

- Container type

- HDPE / PET

- Cap type

- Flat / Sport / Foil aluminum

- Product type

- High/Low acid dairy products

- Control panel type

- HMI/PLC

- Integration possibilities

- Blow-fill technology integration

- Cap size handling

- Flat cap to sport cap

- Bottle type compatibility

- HDPE and PET

- Sterilization technology

- VHP and H2O2

- Foil sterilization

- VHP for aluminum foil

- Bottle changeover

- Automatic