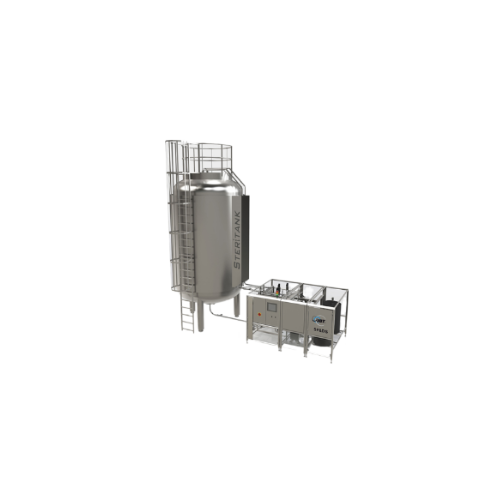

Aseptic storage tank for sterile liquid products

Ensure the sterile safety of your liquid products with a reliable storage solution that seamlessly incorporates sterilization and cleaning processes, reducing contamination risks and maintaining product integrity.

Stores and Sterilizes Aseptic Liquids

The Steritank from JBT FoodTech is an aseptic storage tank designed for processing a diverse range of liquid products, including dairy, beverages, and fruit purees. Built to manage up to 50,000 liters, it ensures consistent sterilization with Sterilization-in-Place and Clean-in-Place systems integrated for automatic operation. The tank utilizes nitrogen blanketing to preserve product quality by reducing oxidation. Constructed for flexible operation, the Steritank supports continuous high-speed production and integrates smoothly within existing processing lines. Its design caters to stringent hygiene standards, making it ideal for producing sterilized milk, purees, and juices. With options for different capacities and durable materials meeting ASME standards, it provides reliable containment and is backed by robust engineering support.

Benefits

- Enhances operational efficiency by integrating seamlessly into existing production lines, boosting throughput.

- Minimizes maintenance costs with built-in Clean-in-Place and Sterilization-in-Place systems.

- Preserves product integrity through nitrogen blanketing, reducing oxidation and extending shelf life.

- Provides flexibility with various capacity options to fit diverse production needs.

- Ensures hygienic processing with compliance to stringent aseptic standards.

- Applications

- Beverages, Soups, Citrus products, Dairy alternatives, Purees, Juices, Vegetable processing, Dairy, Fruit

- End products

- Processed carrot, Apple juice, Broccoli soup, Tomato puree, Orange juice, Almond milk, Aseptic pineapple slices, Mango pulp, Lemon concentrate, Sterilized milk

- Steps before

- Aseptic Processing, Fruit, Vegetable Processing, Juice Preparation, Dairy Processing, Citrus Processing

- Steps after

- Filling, Sealing, Packing, Sterilization

- Input ingredients

- sterile products, liquid products, juices, soups, purees, dairy alternatives, fruit and vegetable products

- Output ingredients

- sterile products, juices, soups, purees, processed dairy alternatives, processed fruit and vegetable products

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Capacity

- 10, 000–50, 000 liters (2, 640–13, 200 gallons)

- Automation

- Fully self-regulating with automatic operating programs

- Pressure

- Full vacuum

- Sterilization method

- Sterilization-in-Place (SIP)

- Cleaning method

- Clean-in-Place (CIP)

- Overpressure system

- Automatic system that maintains constant overpressure

- Nitrogen blanketing

- Yes

- Automation level

- Fully self-regulating with automatic programs

- Cleaning method

- CIP (Clean-in-Place)

- CIP/SIP

- SIP (Sterilization-in-Place)

- Batch vs. continuous operation

- Inline Continuous

- Nitrogen blanketing

- Available

- Overpressure maintenance

- Automatic system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank capacity

- 10, 000 to 50, 000 liters (2, 640 to 13, 200 gallons)

- Tank shape

- Cylindrical

- Control panel type

- Automatic

- Control panel type

- Automatic operating programs