Making Fruit Concentrate

Find innovative production technology for making fruit concentrate and connect directly with world-leading specialists

Originally created to supply US soldiers with vitamin C in World War II, fruit concentrate has found many other uses. Whether you want to drink soda or eat gummy bears, you need fruit concentrate for the color and flavor. The fruit concentrate processing line involves fruit peelers, conveyor belts, filters, and evaporators that help producers make fruit concentrate with all of the fruit’s original aroma.

Stories about fruit concentrate

Tell us about your production challenge

Fruit concentrate processing line

On the fruit concentrate processing line, fruits are washed with an industrial washing machine for fruits and vegetables, cleaned and checked for any anomalies. Then, if needed, industrial fruit peelers peel the fruit. Subsequently, the juice of the fruit is extracted and purified.

To make pure fruit concentrate, the water content is evaporated by increasing the solids content of the juice to 65-75%. To remove water from the fruit juice without damaging it with high temperatures, manufacturers use low temperature evaporators at a maximum temperature of 50 ºC. Heating the juice under low pressure reduces the boiling point which allows the water to evaporate faster.

Challenges in fruit juice concentrate processing – How can you solve them?

During concentration, you can greatly reduce the volume of juice while reducing storage, packaging and transportation costs. Nevertheless, concentration also brings some problems. Fruit juice can lose much of its aroma, color and nutrients during vacuum evaporation. Some other problems are the corruption of the concentrate in form of gel structures and browning during concentration.

To solve the problem of gelling, manufacturers turned to clarification. Clarification generally employs enzyme treatments with pectinase, cellulose, or mixed enzyme formulations which, along with filtration, clarify the juice by breaking down the fruit’s cell walls. Quality losses during evaporation are related to the product’s high temperature and residence time. To overcome this problem, evaporators that use lower temperatures and a short residence time can help maintain the flavor and nutritional content of the fruit. Color changes (browning) can also be avoided by processing and storing the juice at a lower temperature.

Many faces of fruit concentrates

Fruit juice concentrate processing is a complex operation that results in many different products. There are several varieties of fruit juice concentrates and they all vary in their fruit and sugar content. Fruit concentrates without any added sugar are mostly labeled as 100% fruit concentrates and only contain natural sugars.

On the other hand, fruit concentrate that has added sweeteners is used as flavoring in carbonated and noncarbonated drinks, candies and culinary goods. Some of the sweeteners added to fruit concentrate are high-fructose corn syrup, cane sugar or fructose syrup.

Lastly, powdered juice concentrates are made by dehydrating fruit concentrate. Mostly made by spray-drying concentrated fruit juice, powdered juice has a water content of 1-3%. Powdered juice is known for its ability to reduce inflammation and increase antioxidant levels.

Fruit puree vs fruit concentrate: what’s the difference?

Fruit puree and fruit concentrate may seem similar, but their manufacturing processes are quite different. Fruit puree is made from ground and homogenized fruit and has the fruit’s original water content. It is thicker than fruit concentrate and retains all the juice and the fibrous matter that the fruit naturally possesses. Also, fruit puree is deaerated – oxygen is expelled from the puree to prevent oxidization with iron particles in the fruit. It can be used as infant food, as an addition to alcoholic drinks (craft beer and fruit wine) or in jam production. Another similar yet different product is fruit-pulp which often gets confused with puree and concentrate.

On the other hand, fruit concentrate is made from fruit juice and the process requires evaporation. Unlike deaeration, evaporation eliminates the water content from the concentrate, lowering the volume to approximately one sixth of the original juice volume.

Processing steps involved in fruit concentrate making

Which fruit concentrate technology do you need?

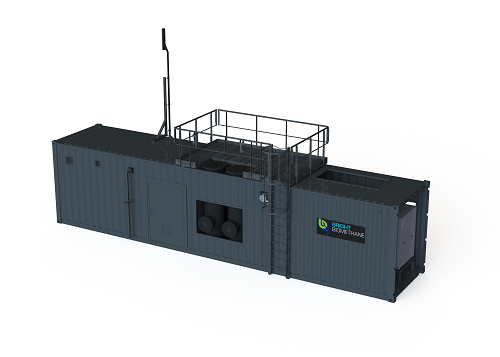

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

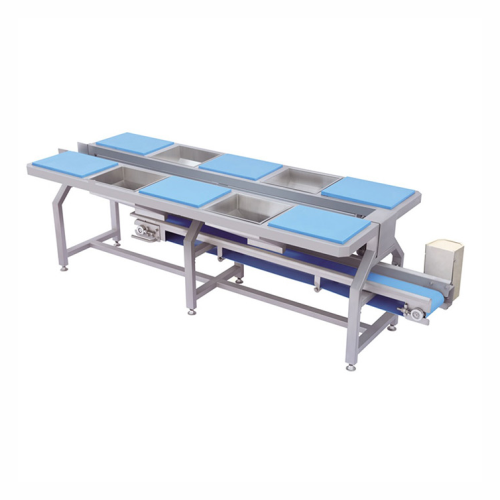

Vegetable and fruit preparation table

Optimize your food processing line with a versatile preparation table designed for ef...

Receiving hopper for jumbo boxes

Efficiently unload and handle bulk agricultural products with ease, streamlining your pre-p...

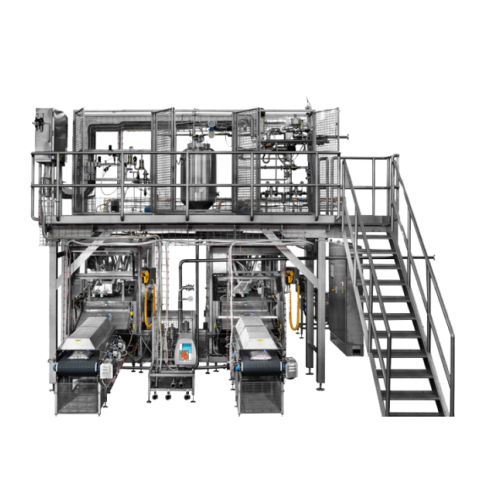

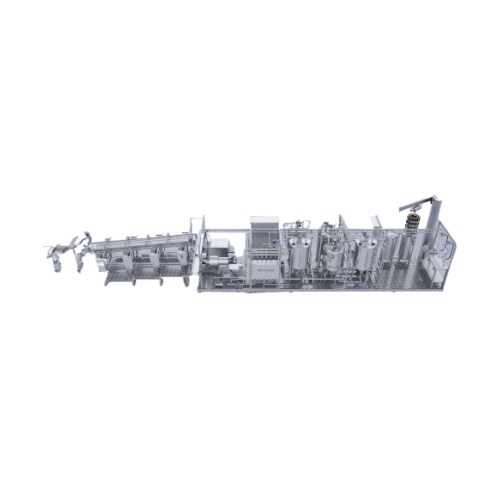

Fruit processing and packaging line

Streamline your fruit and vegetable processing with this semi-automatic system designed...

Grape destemming solution for efficient fruit processing

Streamline your fruit preparation process with a versatile machi...

High-capacity cutting solution for fruits and vegetables

Efficiently transform large volumes of food products into cubes,...

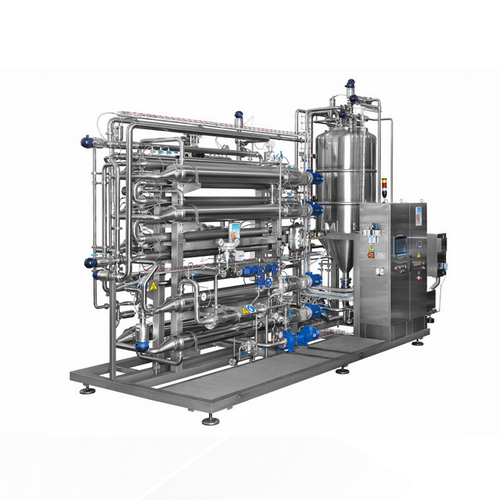

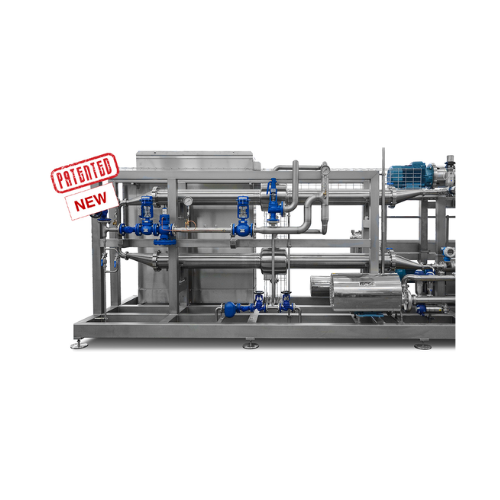

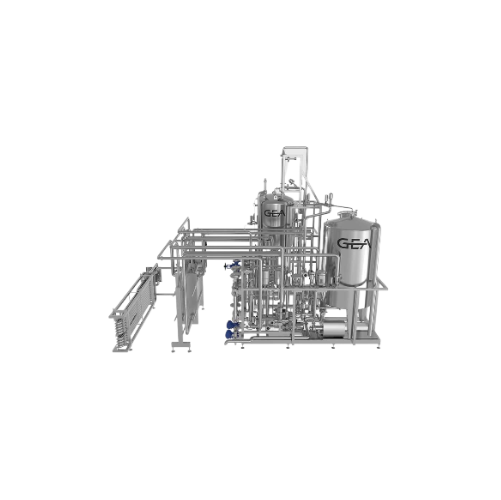

Industrial evaporators for multi-product processing

Optimize your production line with customized evaporators designed fo...

Aseptic sterilizer for fruit-based products

Ensure product safety and extend shelf life with advanced sterilization techno...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Evaporator for pulpy juice concentration

Achieve efficient concentration with reduced energy consumption, thanks to innovat...

Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designe...

Vegetable and fruit dicer

Achieve uniform cuts and reduce waste in your food processing line with a versatile dicer designed...

Fruit processing system for jams and marmalades

Optimize your fruit-based product manufacturing with equipment designed fo...

Concentrate drum emptying system

Efficiently extract every drop of fruit concentrate from your drums with precision and ease...

Enzymatic inactivation system for fruits and vegetables

Achieve optimal product quality by maintaining vivid color, robus...

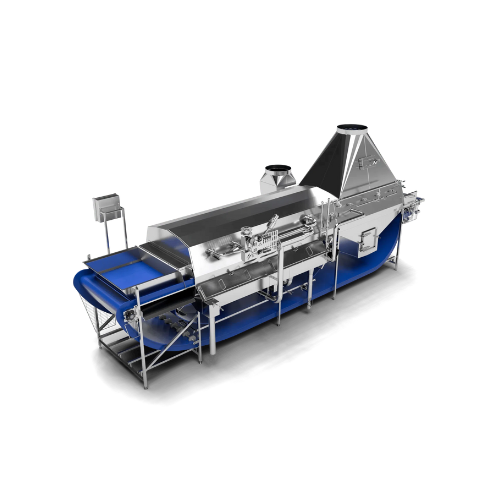

Evaporative blancher for fruits and vegetables

Achieve significant water savings and reduce wastewater generation in your ...

Mash heater for core fruits and berries

Improve juice extraction and color yield in your fruit processing line with this in...

Crusher system for frozen juice processing

Effortlessly process frozen juices and concentrates by efficiently crushing, me...

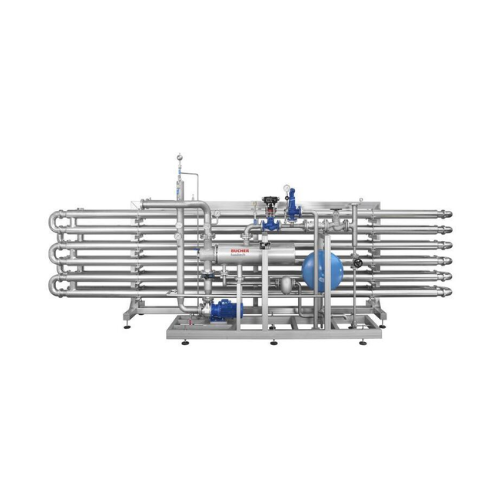

Tubular falling film evaporator for fruit juice concentrates

Optimize your fruit juice concentration process with seamle...

Evaporator for juices and purees

Efficiently concentrate liquid products like apple juice, tomato puree, and chocolate sauce...

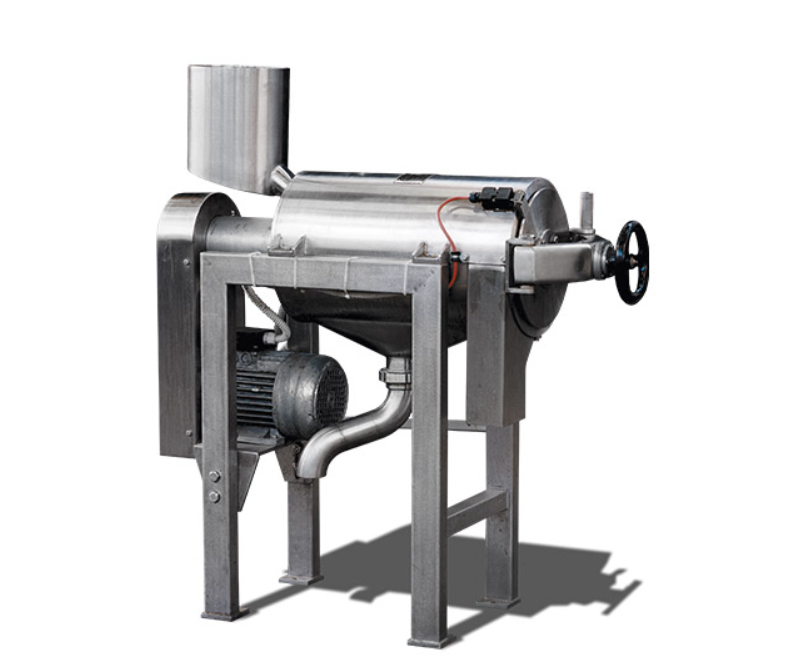

Hammer pulping system for fruit and vegetable processing

Optimize your fruit and vegetable pulping process with a high-sp...

Turbo extractor for puree and concentrate production

Enhance your puree and concentrate production with a turbo extractor...

Fruit and vegetable washing solution with agitating action

Experience efficient dirt removal and product agitation for f...

Sterile cooling system for fruit preparations

For manufacturers seeking aseptic conditions, this cooling system ensures ra...

Ultrafiltration for fruit juices and nectars

Optimize your juice and nectars production with precise ultrafiltration, ensu...

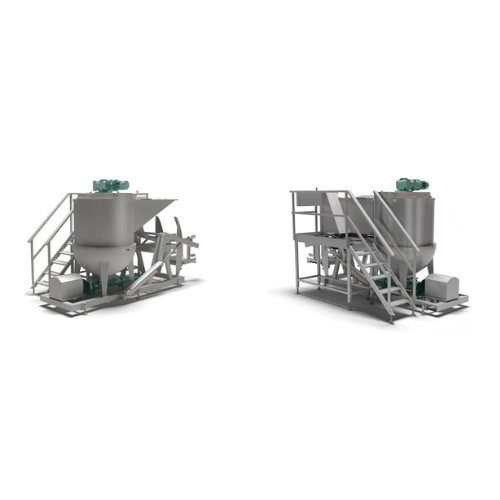

Aroma-batch blender for beverage production

Optimize your beverage formulation process with precise aroma dosing and effic...

Fruit base processing technology for yoghurt and bakery

Ensure the integrity of fruit preparations while maximizing varie...

Washing and sorting line for fruits and vegetables

Efficiently achieve pristine fruit and vegetable cleanliness while enh...

Cold extraction deaeration system for fruit and vegetable purees

Achieve superior puree quality with our system that ens...

Cold extraction and enzymatic deactivation for fruit and vegetable purees

Enhance your puree quality with advanced col...

Aseptic filler for bag in drum or box

Enhance product shelf life and maintain quality without preservatives by employing as...

Aseptic processing equipment for food products

Optimize aseptic processing to ensure microbiological stability and product...

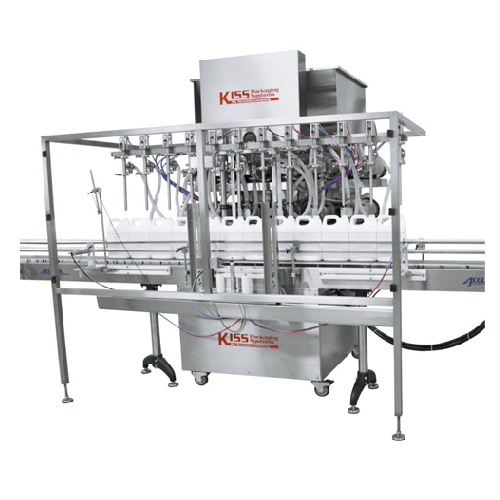

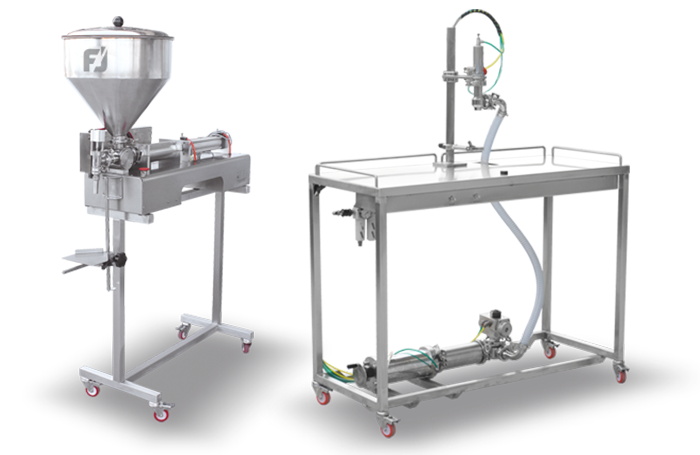

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Semi-automatic piston injector for bakery products

Enhance your bakery production with precise delivery of a wide range o...

Multifunctional washer for fruits and vegetables

Achieve impeccable cleanliness in your food processing line with a versat...

Secondary solids recovery system for citrus pulp

Optimize your juice yield and enhance efficiency with a streamlined four-...

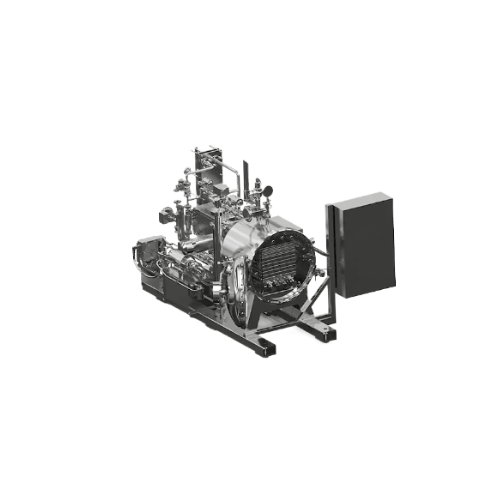

Ohmic heat exchanger for high viscosity foods

Optimize the thermal processing of heat-sensitive foods with precise ohmic h...

Aseptic flash cooling for tomato and fruit concentrates

Achieve seamless aseptic processing while minimizing product degr...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

High speed fruit and vegetable juicer

Optimize your production with a high-capacity juicer designed to efficiently process ...

Industrial bin scrubbing system for fresh produce

Enhance food safety and operational efficiency with a bin scrubbing sys...

Aseptic bag filler for bulk containers

Eliminate spoilage events and ensure sterility in high-speed filling of bulk aseptic...

Industrial chopper/blender for frozen fruit processing

Efficiently transition frozen fruits and concentrates into a manag...

Industrial chopper blender for thawing frozen products

Quickly transform frozen produce into pumpable liquids, optimizing...

Industrial-scale chopper and blender for frozen juice processing

Eliminate lengthy thaw times for frozen concentrates wi...

Pasteurizer for non-alcoholic beverages

Ensure microbiological safety and extend shelf life of your non-alcoholic beverages...

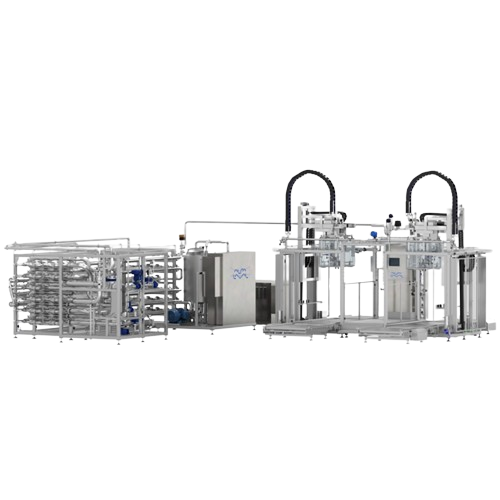

Freeze concentration system for liquid food concentrates

Achieve superior concentration of liquid food products while pre...

Industrial fruit washing and loading hopper system

Streamline your juice production by ensuring optimal fruit preparation...

Industrial multifiller for fruit and vegetable salads

Need to efficiently fill diverse containers with fruit and vegetabl...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Automatic palletizer for fruit and vegetable crates

Optimize your fruit and vegetable handling with efficient palletizati...

Forced circulation fruit juice concentrator

Optimize your fruit juice production with advanced forced circulation technolo...

Multi-fruit extraction line for mango, guava, and passion fruit juice

Optimize your fruit processing with high-yield ex...

Small-scale fruit processing line for juices and sauces

Streamline your small-scale production with a versatile line that...

Multifruit processing line for wholemeal pulps and juices

Optimize your fruit processing capabilities with a skid-based ...

Multifruit processing line for tropical and temperate fruits

Optimize your fruit processing operations with a versatile ...

Nectar formulation line for fruit juices

Optimize your fruit-based product lines with a seamless process that integrates hi...

Peach, plum, and apricot juice processing line

Optimize your fruit processing capabilities with a multifunctional solution...

Pineapple juice extraction line

Streamline your pineapple processing with a complete solution designed to efficiently transf...

Aseptic sterilizers for fruit concentrates and pulp

Optimize your fruit processing by maintaining product quality and she...

Batch evaporators for fruit juice and tomato concentration

Achieve high-quality fruit and tomato concentrates while pres...

Falling film concentrators for low viscosity fruit juices

Achieve high concentration levels in fruit and dairy products ...

Acai berry processing line

Enhance your acai berry production efficiency with an automated line that transforms traditional ...

Apple, pear, and kiwi juice extraction line

Achieve high-yield juice production from apples, pears, and kiwis while retain...

Aroma recovery system for natural juice extraction

Maximize aroma recovery in your juice production with a fully automate...

Drum unloader for liquid ingredients

Unlock efficient unloading of viscous and liquid ingredients without the hassle of lif...

Mango juice production line

Streamline your mango juice production with a complete solution that efficiently transforms fres...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Industrial jam vacuum cooker

In a production setup of agri-food preserves, sauces, and other condiments, vacuum cooking at 5...

Semi-Automatic Volumetric Liquid Filling Machine

Filling containers manually with liquid and viscous products is the metho...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

High pressure processing machine for juice

High-pressure processing (HPP) is one of the technologies in the manufacturing ...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Optical sorter for dried and frozen fruits

Dried fruits, frozen fruits, frozen vegetables and nuts present a challenge for...

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Continuous vacuum belt dryer

For gently drying liquid concentrates into granulates or powders, a vacuum drying solution is t...

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...