Bottle Inspection Equipment

Connect directly with world-leading production technology suppliers of innovative bottle inspection systems

Inspection of jars and bottles is an essential part of any reliable bottle filling operation. Beverage bottles need to be inspected for foreign objects, contaminants, or any residual liquid before filling. After filling, the bottles need to be checked again to ensure the desired fill level, no leaks or potential label problems. Bottles generally travel along conveyors that feed them into the system whereby non-contact optical inspection takes place. This process is usually automated and uses technology to scan the bottles for any potential issues. Considerations for selecting bottle inspection equipment include the size, shape, and material of the bottles, production speed, and the relevant inspection parameters. Bottle inspection equipment is widely used in the food industry to ensure compliance with quality control procedures as well verification.

Which bottle inspection systems technology do you need?

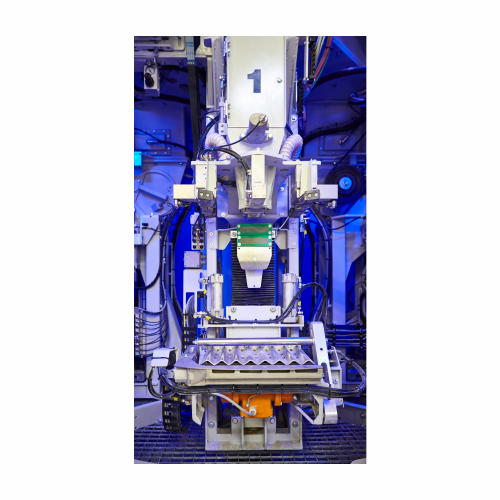

Robotic crating and decrating solution for returnable glass bottles

Streamline your bottling line by efficiently handli...

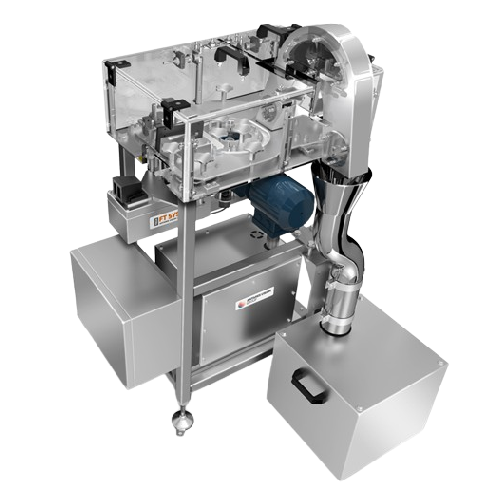

Automatic bottle and vial blower

Ensure purity and compliance in your liquid bottling line with this integrated blowing syst...

External washing and drying system for ampoules and vials

Optimize your aseptic processing by seamlessly integrating a c...

High-speed rotary self-adhesive labelling system for bottles and jars

For cosmetics producers seeking precise and effic...

Glass container inspection system

Ensure product integrity with precision inspection for glass containers, detecting partic...

Inspection for glass containers in pharmaceutical production

Ensure the integrity of freeze-dried products with state-of...

Inspection for glass containers

Ensure the integrity and quality of your liquid formulations with high-speed inspection and ...

Inspection system for plastic ampoules in strips

Ensure the integrity of single-dose plastic containers with high-speed le...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

Inspection system for returnable glass containers

Ensure the safety and quality of your beverage containers with a precis...

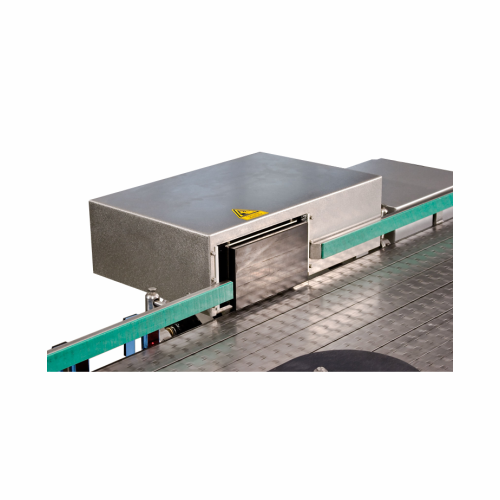

Compact fill level and cap inspection system

Ensure flawless beverage quality by integrating a compact system for precise ...

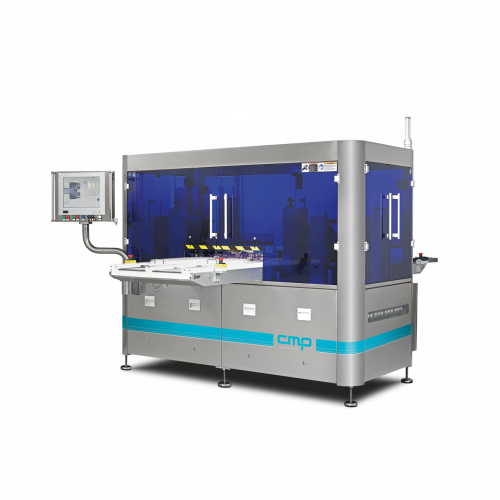

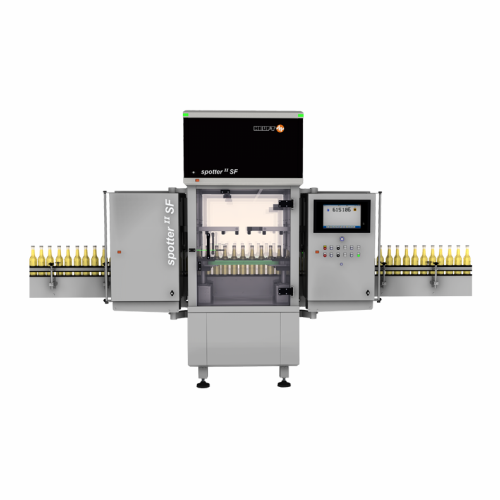

Empty bottle inspector with deep learning

Ensure that every beverage container in your production line is pristine with cu...

Can inspection unit for quality control

Ensure the integrity of your beverage cans with precise defect detection and qualit...

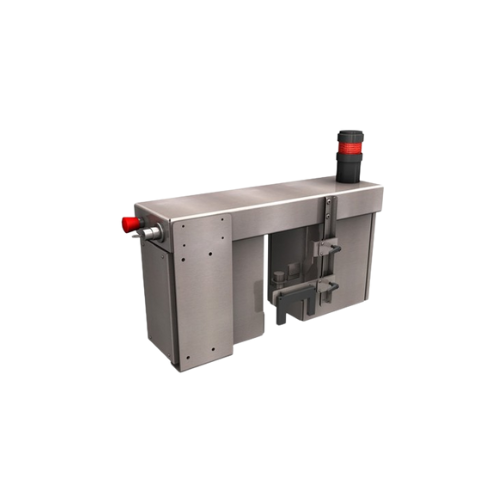

Caustic residue detection for bottle washing

Ensure product purity by detecting and eliminating residual caustic in return...

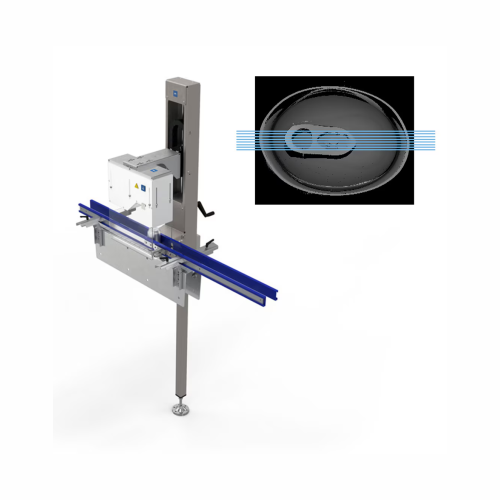

Leakage detection for beverage cans

Ensure each canned beverage leaves your facility ready to impress, with precise leak de...

Preform and container inspection system

Ensure only flawless preforms and bottles continue in your production line with an ...

Bottle inspection system for foreign particles detection

Ensure your beverage products remain uncontaminated with high-pr...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

Closure inspection system for crown corks and metal caps

Ensure product integrity with high-speed 360° closure inspection...

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

Closure inspection system for beverage caps

Ensure complete closure integrity in high-speed beverage production lines with...

High-precision fill level checker for beverages and containers

Ensure precise fill levels and prevent product wastage by...

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

Container ejection system for Pet bottles and beverage cans

Ensure product quality by seamlessly ejecting defective cont...

Container rejection system for high-speed operations

Ensure product safety by swiftly removing defective containers at hi...

Inline bottle cleaner for pharmaceuticals

Ensure your pill bottles and capsule containers are free from contaminants with ...

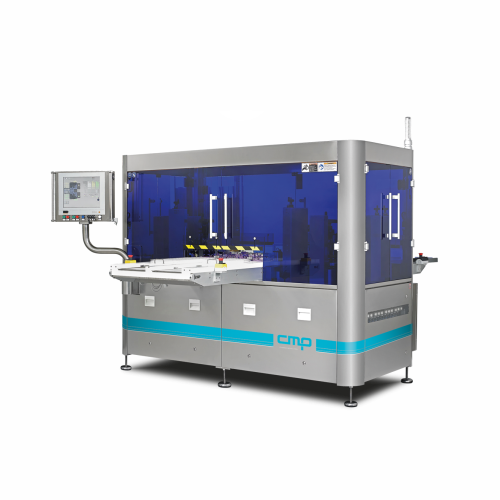

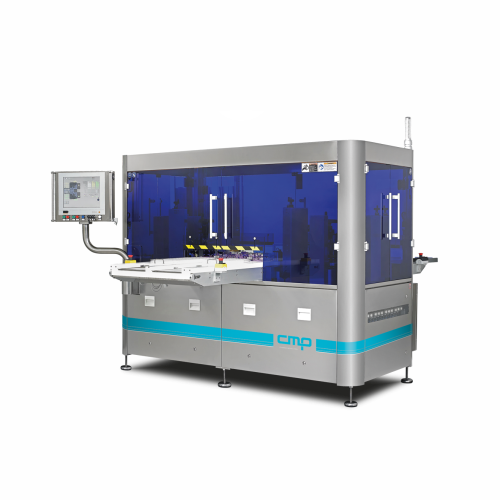

Compact full product inspection system for pharmaceuticals

Easily detect fill level inaccuracies, closure misalignments,...

Empty container inspection for pharma packaging

Ensure ultra-clean packaging by detecting glass faults and contaminants be...

Industrial case rejector for faulty packaging

Ensure product integrity by smoothly removing faulty cases from your product...

Industrial container rejector for faulty product removal

Ensure seamless removal and sorting of defective containers in h...

Full container check for fill level and closure inspection

Ensure the integrity of your liquid products with this advanc...

Final product inspection system for pharmaceutical containers

Ensure the integrity and precision of packaged pharmaceuti...

Full container inspection for pharma and food industries

Ensure precise fill levels and secure closures in your productio...

Full container inspection for glass and Pet bottles

Ensure the highest product quality by detecting foreign objects and m...

Closure inspection for beverage containers

Ensure the integrity of your bottled products with precision closure inspection...

Automatic leakage detection for Pet bottles

Ensure the integrity of bottled beverages by detecting even the smallest leaks...

Ultrasonic leak detection system for carbonated beverages

Ensure the integrity of your carbonated beverages by precisely...

Semi-modular labeller for precise beverage bottle labelling

Achieve millimeter-precision bottle labelling with seamless ...

Empty can inspection system for food industry

Ensure seamless production flow by detecting faulty cans before filling, pre...

X-ray assisted empty container inspection system

Detect low-density foreign objects and micro-cracks in empty containers w...

X-ray assisted empty bottle inspection

Enhance your production line with advanced X-ray and optical technology to ensure pr...

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Final container inspection for beverages

Ensure flawless product presentation and secure branding by detecting misaligned l...

Advanced foreign object inspection for full beverage containers

Ensure consumer safety and brand protection with advance...

Full case check for beverage production lines

Ensure complete packaging integrity by detecting and removing cases with mis...

Full container inspection system

Ensure the quality and safety of your products with a compact solution that performs precis...

Full container check system for beverage industry

Streamline your quality assurance process with advanced detection techn...

Heuft container rejector for beverage and food industries

Ensure flawless product flow by efficiently removing faulty or...

Conveyor control system for beverage filling lines

Optimize your production line’s efficiency by seamlessly managin...

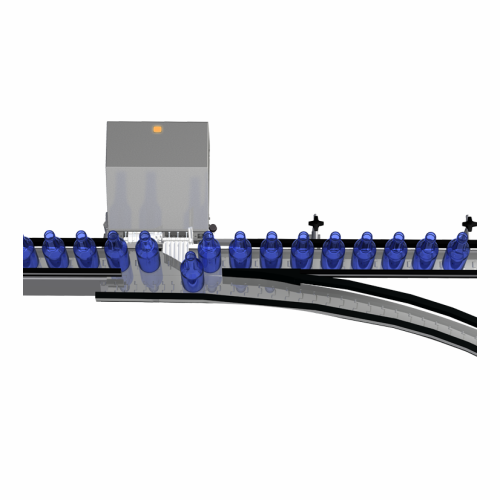

Curve rejector for beverage containers

Ensure seamless and upright rejection of faulty containers in tight spaces, maintain...

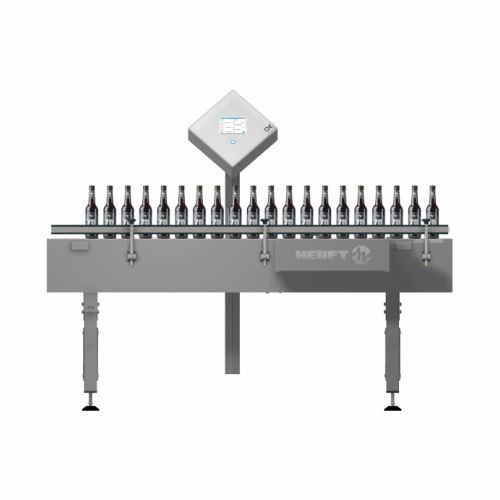

Empty bottle inspector for beverage industry

Ensure flawless quality control by thoroughly inspecting empty bottles for de...

Empty bottle sorting system

Efficiently remove unstable, misshapen, and contaminated empty bottles before they disrupt your ...

Rotating packaging system for cement and chemicals

Streamline your packaging line with a high-speed, rotating solution th...

Self-adhesive labeling system for unstable cylindrical containers

Ensure precise labeling of unstable cylindrical conta...

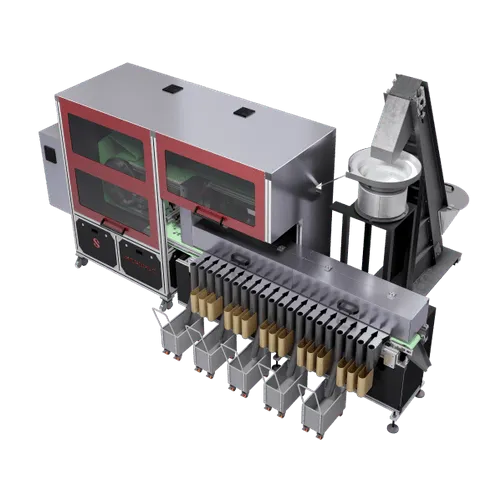

Integrated bottling center for pharmaceutical tablets and capsules

Enhance your production line with versatile bottling...

Automated ioflupane i-123 injection dispensing solution

Ensure precision and efficiency in radiopharmaceutical production...

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

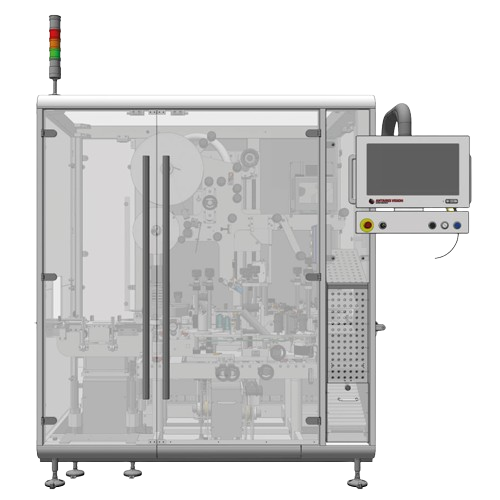

Self-adhesive labeling system for bottles

Streamline your bottling operations with high-precision labeling that enhances p...

High-speed horizontal case packer for shipping cases

For high-demand production lines, this modular case packer streamlin...

Inspection system for filled glass bottles

Ensure high-quality beverage bottling by detecting bottle faults, contaminants,...

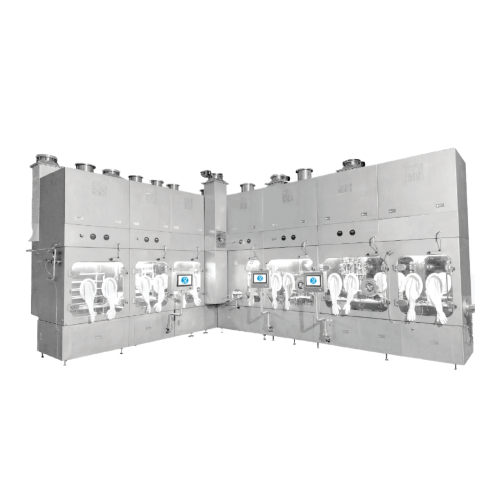

Aseptic filling and closing for flexible Iv bags

Streamline your production line with high-speed aseptic filling and seali...

Filling and closing solution for vials and syringes

Achieve precise aseptic fill-finish of liquid formulations in vials a...

Automated quality control for beverage packaging

Streamline beverage quality control with 24/7 automated analysis, ensurin...

Packaged beverage analyzer for alcohol and Co2

Ensure precise beverage analysis with a streamlined solution that integrate...

Print and verify cartons packaging systems

Streamline your packaging line with a versatile solution that prints, verifies,...

Pressure measurement system for bottle leak detection

Ensure the integrity and quality of your packaged products by accur...

Empty can inspection system for defect detection

Ensure the integrity and quality of your canned products by swiftly detec...

Preform inspection system for blown containers

Ensure defect-free blown containers and minimize line jams with a robust pr...

Thread neck inspection for beverage bottles

Ensure bottle closure integrity by detecting subtle thread defects, such as cr...

Fill level inspection system for beverage bottling

Ensure compliance and optimize quality control with a system that accu...

In-line leak detection system for beer bottles

Ensure beer quality by detecting leaks and measuring pressure in every bott...

Cap quality inspection system for beverage industry

Ensure flawless cap performance and prevent production disruptions wi...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

Application angle inspection for Pet bottle caps

Ensure perfect cap alignment on PET bottles to prevent leaks and ensure e...

Blown bottle inspection system

Ensure the integrity and quality of your plastic containers with a high-speed inspection syst...

Automatic bottle self adhesive labeling solution

Enhance your production line with precision labeling for diverse containe...

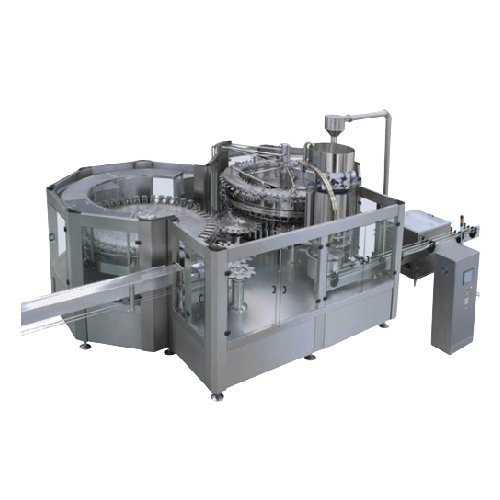

High-capacity carbonated drink filling system

Optimizing your carbonated beverage production, this high-speed filling syst...

Rotary bottle rinser for high-speed production lines

Ensure thorough cleaning and preparation of containers with a high-s...

High-speed bottle orientator

Efficiently streamline your bottling process by ensuring containers are swiftly and accurately ...

Inspection-rejection station for bottled products

Ensure your bottled and packaged products ship defect-free by automatic...

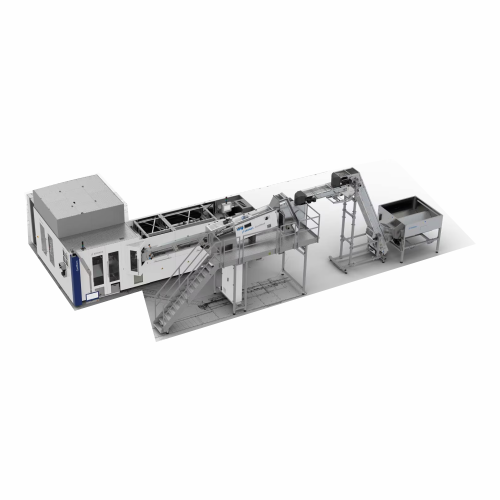

Glass bottle washing and delabelling system

Effortlessly transform used bottles into pristine, reusable containers with th...

Automatic packing, capping, and labelling line for juice products

Streamline your juice production process with an inte...

Modular and combined labeling machines for bottling

Achieve high-speed labeling with unmatched flexibility, combining mul...

Hot fill bottling unit for juices and isotonic beverages

Ideal for producers handling delicate or specialty liquids, this...

X-ray scanner for contaminant detection in packaging

Ensure your products remain contamination-free with advanced X-ray s...

Dual view x-ray inspection for canned goods

Enhance your production line with advanced dual-view X-ray inspection, ensurin...

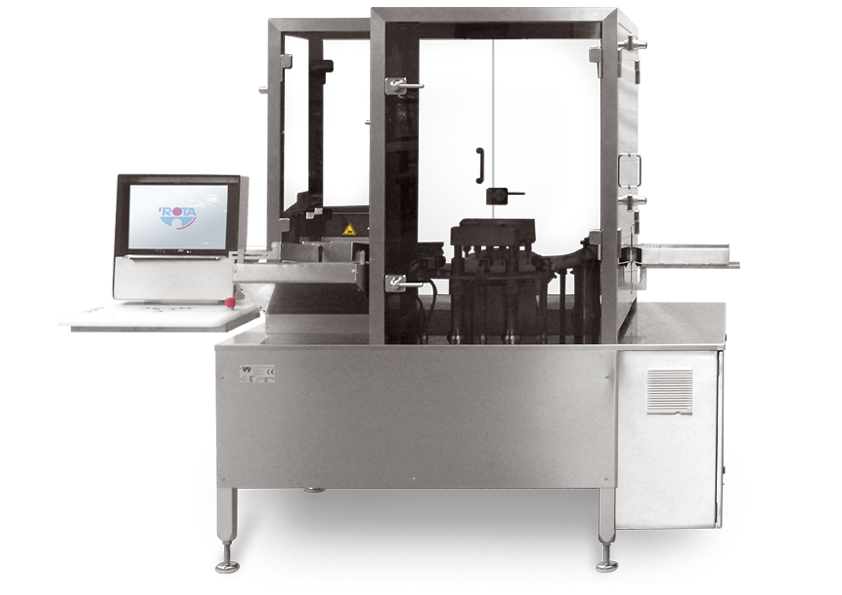

Bottle and vial inspection and coding system

Ensure seamless coding and inspection of vials and bottles with rapid 360° ev...

Leak testing system for aerosol cans

Ensure the integrity of your aerosol and metal packaging with a high-speed leak testin...

Combined Avi and Cci tester for vials

Ensure comprehensive quality control of parenteral products with an integrated soluti...

Omnidirectional inspection system for bottles and vials

Ensure precise serialization and aggregation with a 360° inspecti...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Automatic inspection system for ampoules and vials

Ensure precision in pharmaceutical production with a comprehensive ins...

Dual filling solution for tetra top packages

Boost production flexibility by simultaneously filling different liquid produ...

Combined air water rinser for bottles and jars

Optimize your bottling process with an integrated solution for rinsing and ...

Online tablet counter inspection system

Ensure product integrity by precisely inspecting and rejecting defective tablets an...

Automated coin classification and sorting system

Achieve precise coin classification and sorting with unparalleled accurac...

Bottle induction seal integrity inspection

Ensure uncompromised product quality by accurately inspecting and verifying the...

Motorized cap torque tester for bottle closures

Ensure precise seal integrity and compliance with bottle cap torque measur...

Ampoule filling and sealing line

Streamline your ampoule production with an integrated solution that expertly handles everyt...

Pet bottle production for small and medium outputs

Optimize your production line by manufacturing PET bottles in-house, r...

Space-saving packaging solution for high-velocity production

Optimize your manufacturing floor space with a versatile in...

Laboratory liquid viewer for colored glass bottles

In the pharmaceutical industry, an inspection to detect any particulat...

Laboratory liquid viewer for varying light conditions

In the pharmaceutical industry, you must inspect liquids in vials o...

Laboratory liquid viewer for transparent glass bottles

Impurities like hair, fibers, or glass, sourced from the environme...

Dessicant inserting machine

Desiccant canisters play an important role in the pharmaceutical and nutraceutical industries. T...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Pharmaceutical bottles inspection machine

For the visual inspection of small to medium batch-sizes of vials, ampoules or b...

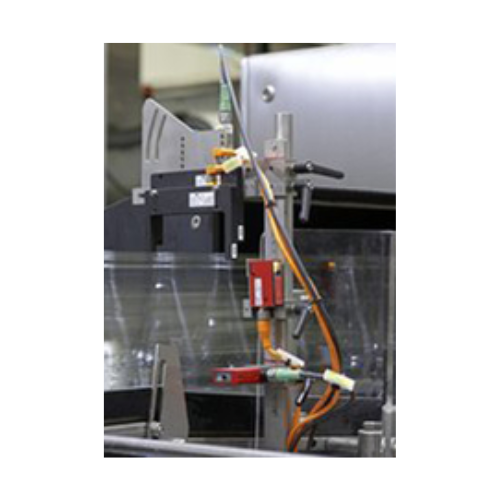

Advanced residual liquid inspection system

Advanced and easy to use inspection system that eliminates the risk of residual...