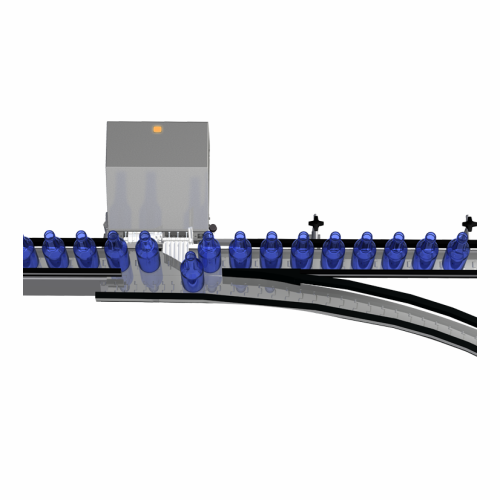

Curve rejector for beverage containers

Ensure seamless and upright rejection of faulty containers in tight spaces, maintaining flow efficiency without interruptions on high-speed lines.

Rejects and Redirects Faulty Containers Upright

The HEUFT LAMBDA-K from HEUFT SYSTEMTECHNIK is a compact curve rejector designed for seamless integration into beverage, food, and pharmaceutical packaging lines. This equipment stands out with its ability to precisely reject and redirect faulty or non-brand containers, maintaining their upright position even in high-speed environments.

Utilizing advanced conveyor mechanics and the HEUFT DELTA-K multi-segment rejection system, it minimizes container resistance and ensures a smooth, harmonic rejection curve. This is essential for handling unstable containers like empty PET bottles.

Ideal for applications involving beverages such as carbonated soft drinks, craft beer, and pharmaceutical syrup bottles, the HEUFT LAMBDA-K efficiently manages up to 60,000 containers per hour. It allows for easy brand changes with precise digital adjustments to accommodate different container formats and weights.

The unit is PLC-controlled for effortless integration into existing lines, offering space-saving benefits without sacrificing performance. Its design is robust, ensuring long-term operational efficiency, while its compact footprint makes it suitable for areas with spatial constraints. Additionally, the equipment adheres to industry standards, supporting both solid and liquid product types in packaging and transport departments.

Benefits

- Enhances operational efficiency by rejecting up to 60,000 containers per hour without interruptions.

- Saves valuable floor space with its compact design for tight production areas.

- Facilitates seamless brand transitions with easy and precise adjustments.

- Minimizes container breakage by maintaining an upright position during rejection.

- Integrates easily into existing high-speed lines, reducing installation costs and complexity.

- Applications

- Food, Beverages, Labelling, Container transport, Full containers, Empty containers, Fault rejection, Pharmaceuticals

- End products

- Bottled sauces, Packaged condiments, Processed canned vegetables, Personal care product bottles, Pet beverage bottles, Aluminum beverage cans, Craft beer bottles, Pharmaceutical tablets in bottles, Packaged fruit juices, Plastic medicine bottles, Pharmaceutical syrup bottles, Flavored tea bottles, Carbonated soft drinks, Ready-to-drink coffee cans, Vitamin supplement containers

- Steps before

- Filling, Labelling

- Steps after

- Packing, Inspection

- Input ingredients

- faulty containers, non-brand bottles, empty PET bottles, full containers

- Output ingredients

- upright rejected containers, redirected containers, stable removed containers

- Market info

- HEUFT is known for its expertise in inline quality inspection systems and automation solutions for the food, beverage, and pharmaceutical industries, with a reputation for innovation and reliability in ensuring product safety and integrity.

- Capacity

- up to 60, 000 containers/hr

- Speed

- High-speed rejection

- Automation

- Clever conveyor control system

- Flexibility

- Easy brand and program changes

- Space Requirement

- Compact construction

- Rejection System

- Multi-segment with harmonic rejection curve

- Container Type

- Bottles and cans

- Adjustment

- Precise vertical and horizontal adjustment

- Working mechanism

- Upright high-speed rejection

- Integrated steps

- Fault rejection around a curve

- Changeover time

- Simple and fast brand changes

- Automation level

- Intelligent conveyor control system

- Resistance to container material

- Glass, PET, metal

- Abrasion resistance

- Yes

- Cleanability

- High

- Corrosion resistance

- Yes

- Durability under high-speed conditions

- Yes

- Container type

- Bottles / Cans / PET

- Container size and shape

- Variable / Slim

- Stability of container

- Wobbly / Unstable

- Compact footprint

- Yes, space-saving design

- Discharge method

- Curve rejection

- Control panel type

- Digital display

- Machine footprint

- Extremely compact

- Conveyor Type

- Single-lane, slim, curved conveyor