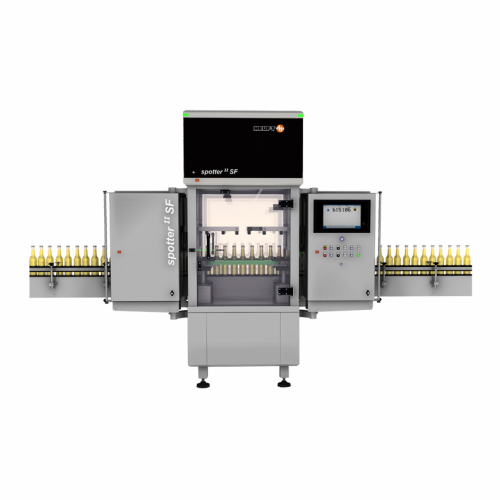

Full container inspection for glass and Pet bottles

Ensure the highest product quality by detecting foreign objects and material defects in full glass and PET bottles with precision and reliability.

Inspects and Rejects Contaminated Full Containers

The HEUFT Spotter II SF, part of the HEUFT SYSTEMTECHNIK lineup, is a highly automated full container optical inspection system engineered for rigorous quality control in beverage, food, and pharmaceutical production. This system stands out for its capability to conduct complete 360° inspections of glass and PET bottles, identifying low-density foreign objects like film, paper, and insects in transparent liquids. Utilizing the HEUFT SPECTRUM II platform, it integrates optical base and sidewall inspections with HEUFT reflexx A.I. real-time image processing for exceptional detection reliability.

The system’s servo-controlled alignment ensures effective inspection coverage, increasing throughput with a capacity of up to 72,000 bottles per hour. With automated brand changes and the HEUFT NaVi user guidance, it seamlessly adapts to different container formats, enhancing operational efficiency. Its network capabilities facilitate remote monitoring, while HEUFT CleanDesign prioritizes hygiene with sloping surfaces for easy cleaning. Highly modular, the system can integrate optional modules for fill level, closure, and label inspection, making it a versatile choice for maintaining product safety and compliance in dynamic production environments.

Benefits

- Enhances product quality by identifying and rejecting contaminants in full containers, minimizing recall risks.

- Increases production efficiency with a high throughput capacity of up to 72,000 bottles per hour.

- Reduces operational errors with fully automated brand and format changes.

- Promotes easy maintenance and hygiene with HEUFT CleanDesign, facilitating quick cleaning and preventing contamination.

- Supports seamless integration into existing production lines with networked monitoring and control capabilities.

- Applications

- Food, Transparent liquids, Pet bottles, Beverage, Pharma, Glass bottles

- End products

- Beer bottles, Pharmaceutical syrups, Bottled sauces, Liquid medicines, Wine bottles, Vinegar bottles, Mineral water bottles, Soda bottles, Cooking oil bottles, Salad dressings, Fruit juice bottles, Liquid supplements, Bottled iced tea

- Steps before

- Filling, Capping, Labeling

- Steps after

- Packing, Distribution, Quality control

- Input ingredients

- glass bottles, PET bottles, transparent liquids

- Output ingredients

- inspected bottles, rejected faulty containers

- Market info

- HEUFT is known for its expertise in inline quality inspection systems and automation solutions for the food, beverage, and pharmaceutical industries, with a reputation for innovation and reliability in ensuring product safety and integrity.

- Detection type

- Optical

- Inspection coverage

- 360° sidewall, complete container base

- Capacity

- up to 72, 000 bottles per hour

- Automation

- Highly automated

- Container type

- Glass / PET

- Rejection system

- Single-segment and multi-segment

- Real-time monitoring

- HEUFTreflexxA.I

- Adjustment features

- Servo-controlled alignment and belt drive

- Image processing

- Real-time with AI

- User guidance

- HEUFTNaVi

- Automation level

- Highly automated, PLC-based

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Automatic brand and format changes

- CIP/SIP

- Cleaning Optimized for Hygiene

- Energy efficiency

- Maximized due to advanced control systems

- Cleaning method

- HEUFTCleanDesign principles

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Glass / PET

- Container size

- Various

- Defect types

- Scratches / Cracks / Inclusions / Chips

- Foreign object detection

- Film remnants / Paper bits / Insects / Mould

- Product transparency

- Transparent liquids

- Control panel type

- Touchscreen

- Control panel type

- Touchscreen with audiovisual guidance

- Integration possibilities

- Network-based remote maintenance and documentation

- Adjustability

- Automatic brand and format changes

- Platform

- HEUFT SPECTRUM II with multiprocessing capability

- User guidance system

- HEUFT NaVi with audiovisual assistance

- Network connection

- Gigabit Ethernet and TCP/IP support