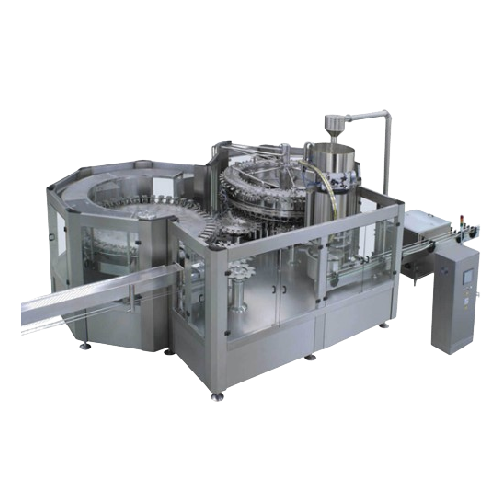

High-capacity carbonated drink filling system

Optimizing your carbonated beverage production, this high-speed filling system integrates washing, filling, and capping to enhance efficiency and ensure precision with each bottle.

Fills, Washes, and Caps Carbonated Beverages

The 10000BPH Carbonated Drink Filling Machine, Model DCGF32-32-10, from Alps Machinery, offers an automated solution for efficient beverage production. This equipment is engineered for optimal integration into carbonated drink bottling lines, handling tasks such as washing, filling, and capping. It operates using an isobaric filling type, which ensures precision and stability, and accommodates various PET bottle sizes (250ml to 2L). With a throughput of up to 10,000 bottles per hour, it caters to the needs of carbonated beverage, soda, and energy drink manufacturers.

The machine’s construction features 304 stainless steel for all parts in contact with the product, ensuring durability and easy maintenance. Its high-precision filling nozzles are PLC-controlled, maintaining consistent fill levels. The capping system, equipped with electromagnetic heads, minimizes bottle crashes, guaranteeing operational efficiency. The DCGF32-32-10’s design emphasizes hygienic processes, incorporating aseptic water for washing, and necessitating less water usage while achieving complete cleanliness. Its compact footprint and comprehensive engineering support make it a versatile choice for high-demand production environments.

Benefits

- Enhances production efficiency with high-speed operation up to 10,000 bottles per hour.

- Minimizes water usage during washing, promoting cost-effective and sustainable practices.

- Maintains product integrity and reduces waste with precise PLC-controlled filling and capping.

- Optimizes line integration and changeover flexibility with adjustable settings for various bottle sizes.

- Ensures long-term operational reliability with durable stainless steel construction.

- Applications

- Soda water, Carbonated soft drinks, Energy drinks

- End products

- Club soda, Diet soda, Tonic water, Sports drinks, Lemon-lime soda, Ginger ale, Sparkling water, Flavored seltzer, Cola, Energy drink with caffeine

- Steps before

- Water Treatment, Bottle Blowing, Beverage Preparation

- Steps after

- Labeling, Packing

- Input ingredients

- PET bottles, screw caps, aseptic water, compressed air

- Output ingredients

- carbonated drinks, CSD drinks, soda water, energy drinks, filled PET bottles

- Market info

- Alps Machine is known for specializing in the design and manufacturing of industrial engineered-to-order equipment, providing innovative solutions and reliable machinery tailored to the specific needs of industries like beverage and packaging.

- Capacity

- 8000–10000 Bottles/hour

- Bottle Sizes

- 250ml ~ 2000ml

- Automation

- Automatic, PLC-controlled

- Filling type

- Isobaric filling type

- Suitable bottle shapes

- PET Circular or Square

- Bottle diameter

- Dia50 ~ Dia115mm

- Bottle height

- 150 ~ 320mm

- Compressor air

- 0.3 ~ 0.7 Mpa

- Washing medium

- Aseptic water

- Total power

- 7.2kw

- Overall dimensions

- 4.2 X 2.2m

- Height

- 2.5m

- Weight

- 7000kg

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- CIP compatible

- Cleaning method

- CIP / Manual

- Energy efficiency

- 7.2 kW total power

- Abrasion resistance

- SUS304/316

- Biological compatibility

- Food-grade

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel

- Machine footprint

- 4.2m x 2.2m x 2.5m

- Weight

- 7000 kg

- Adjustable bottle sizes

- 250 ml – 2 L

- Integration possibilities

- Automatic control via PLC