Inspection for glass containers

Ensure the integrity and quality of your liquid formulations with high-speed inspection and leak testing for ampoules, vials, and cartridges, providing precise filling level and cosmetic control.

Inspects and Tests Glass Containers for Quality Assurance

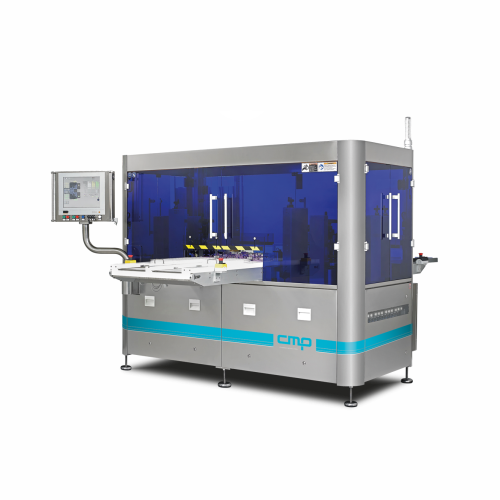

The SA Series from Marchesini Group comprises inspection machines designed for ampoules, vials, and cartridges, offering pharmaceutical and biopharmaceutical companies a precise and reliable solution for quality assurance. What sets the SA Series apart is its ability to perform comprehensive inspections, including leak testing, filling level checks, and cosmetic and color controls, using a combination of backlights and bottom lights coupled with advanced CMP software. The machines can process up to 400 pieces per minute, allowing for high-speed continuous operations essential for maintaining production efficiency.

These machines are particularly relevant for industries dealing with liquid formulations, such as vaccines, insulin solutions, and chemotherapy drugs. They ensure the integrity and safety of end-products, including vials and ampoules, through thorough inspections for extraneous particles and defects. The SA Series offers flexible integration options, such as connecting with leak test units to further enhance container integrity assessments.

Designed to meet various compliance standards, the SA Series is an ideal choice for laboratories and processing departments in pharmaceutical manufacturing. Its CIP system facilitates easy, contamination-free cleaning, and the equipment can be customized to match operational needs, with support for different diameters and heights. This adaptability ensures seamless fit into existing production environments, enhancing both efficiency and quality control processes.

Benefits

- Enhances product integrity with comprehensive inspection capabilities, reducing defect rates.

- Increases production efficiency through high-speed processing of up to 400 pieces per minute.

- Customizable configurations allow seamless integration into various production lines.

- Ensures compliance with industry standards, supporting critical pharmaceutical applications.

- Minimizes contamination risks with efficient cleaning and maintenance via CIP systems.

- Applications

- Liquid formulations, Nutraceuticals, Vials, Ampoules, Biopharmaceuticals, Cartridges, Pharmaceuticals

- End products

- Antibiotic vials, Vaccines, Vitamin d supplements, Eye drop vials, Nutrient supplement vials, Chemotherapy drugs, Insulin solutions, Essential oil cartridges, Saline ampoules, Hormonal injections

- Steps before

- Washing and Sterilizing, Filling

- Steps after

- Packaging, Leak Testing

- Input ingredients

- ampoules, vials, cartridges, containers, extraneous particles, fibres, glasses

- Output ingredients

- inspected ampoules, inspected vials, inspected cartridges, correct filling level, tip/cap cosmetic control, ring/cap colour control, color of the product, printing, sidewalls glass defects inspected, plunger inspection for cartridges

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Inspection Speed

- Up to 400 pcs/min

- Image Acquisition

- Up to 30 images per camera

- Supported Container Types

- Ampoules, vials and cartridges

- Capacity Range

- 1 ml to 30 ml

- Diameter Range

- 8 mm - 32 mm

- Height Range

- Up to 120 mm

- Inspection Types

- Extraneous particles, fibres, glasses, filling level

- Optional Inspections

- Tip/cap cosmetic control, Ring/cap colour control, Product colour, Printing, Sidewalls glass defects, Plunger inspection

- Automation level

- PLC / CMP software

- Batch vs. continuous operation

- Batch

- Cleaning method

- CIP possible

- Integration with leak test

- Possible

- Customization options

- Back and bottom lights

- Container type

- Ampoules, Vials, Cartridges

- Machine footprint

- Compact

- Container type

- Ampoules, vials, cartridges

- Control panel type

- Customizable via CMP software

- Integration possibilities

- Integration with leak test unit

- Lighting options

- Back and bottom lights

- Software customization

- Customizable CMP software