Inspection for glass containers in pharmaceutical production

Ensure the integrity of freeze-dried products with state-of-the-art inspection technology, capable of detecting foreign particles, checking oxygen levels, and assessing cosmetic defects, all while maintaining high production speeds.

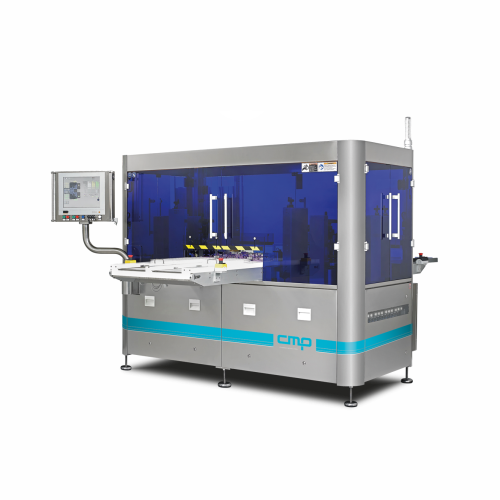

Inspects Glass Containers for Defects and Contamination

The SA-L Series from Marchesini Group offers pharmaceutical and biotech industries a robust solution for inspecting freeze-dried products in glass containers. Utilizing high-quality CCD and linear TV cameras, this fully automatic inspection machine excels in identifying foreign particles, cosmetic defects, and ensuring container integrity through oxygen control via a TDLAS system. Suitable for lyophilized vaccines and antibiotics, it achieves a production speed of up to 300 pcs/min for containers with diameters between 8 mm and 46 mm, and heights up to 120 mm. Easily integrated into existing production lines, the SA-L Series offers tray operation or inline configurations with other units, enhancing throughput and quality control in demanding environments. Crafted for efficiency, it supports compliance with industry standards, providing pharmaceutical manufacturers and biotech companies with reliable quality assurance backed by Marchesini’s global support network.

Benefits

- Enhances product quality by efficiently detecting contamination and defects.

- Increases production speed up to 300 pcs/min, streamlining operations.

- Ensures container integrity with advanced oxygen control capabilities.

- Adapts to existing production lines for seamless integration.

- Supports compliance with industry standards for quality assurance.

- Applications

- Freeze-dried products, Pharmaceutical products

- End products

- Lyophilized vaccines, Biopharmaceutical powders, Freeze-dried nutritional supplements, Lyophilized biological samples, Freeze-dried antibiotics

- Steps before

- Freeze-drying, Container preparation

- Steps after

- Packaging, Quality control

- Input ingredients

- freeze-dried products, glass containers, containers up to 46 mm diameter

- Output ingredients

- inspected glass containers, up to 300 pcs/min

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Production speed

- Up to 300 pcs/min

- Container diameter

- 8 mm - 46 mm

- Container height

- Up to 120 mm

- Automation

- Fully automatic

- Inspection technology

- CCD and linear TV cameras

- Oxygen Control

- Laser (TDLAS system)

- Working Mechanism

- Fully automatic inspection

- Automation level

- PLC / Automated

- Production Speed

- Up to 300 pcs/min

- Inspection Capability

- Combination of CCD and linear TV cameras

- Operation Mode

- Trays or in line with other units

- Oxygen Control

- TDLAS system

- Container Size Compatibility

- 8 mm - 46 mm diameter

- Product Type

- Freeze-dried products

- Automation level

- PLC-based

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Type

- Freeze-dried products

- Diameter range

- 8 mm - 46 mm

- Height range

- Up to 120 mm

- Production speed

- Up to 300 pcs/min

- Camera type

- CCD and linear TV cameras

- Tray or in-line operation

- Tray / In-line with other units

- Oxygen control system

- TDLAS system

- Integration with other units

- In-line operations

- Oxygen control system

- TDLAS system

- Camera types

- CCD and linear TV cameras

- Operation method

- Trays or in-line