Cap quality inspection system for beverage industry

Ensure flawless cap performance and prevent production disruptions with precise inspections that detect defects before caps reach the bottling line.

Inspects and Detects Defective Bottle Caps

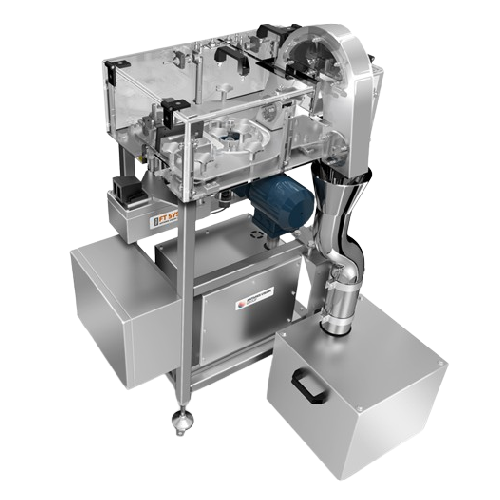

The QT 700-IoT Cap Quality Inspection System from Antares Vision Group is designed to enhance production efficiency by detecting defective bottle caps before they reach the capping stage. This system employs advanced artificial vision technology integrated into the cap chute to identify issues such as upside-down caps, ovalisation, and security ring defects. Ideal for beverage and packaging industries, it supports continuous, high-speed operations, making it suitable for bottling companies and packaging firms working with plastic and sport caps. The QT 700-IoT offers factory-friendly integration with features like real-time production records and picture storage. Its user-friendly interface allows for seamless expansion with additional inspections, further reducing costs by minimizing jams and claims. Optional integration with the Arol flex cap elevator provides enhanced versatility for different production line configurations, ensuring correct bottle closure and maintaining product quality.

Benefits

- Enhances production efficiency by reducing cap-related jams and downtime.

- Lowers operational costs through early detection of defective caps.

- Ensures optimal product quality with reliable closure integrity.

- Supports seamless production line integration with robust data management.

- Minimizes market claims by assuring consistent cap inspection accuracy.

- Applications

- Water, Beverage, Sports drinks, Energy drinks, Bottling, Juice, Soft drinks

- End products

- Sport caps, Plastic caps, Bottle caps, Closure seals

- Steps before

- Cap production, Cap sorting, Cap feeding

- Steps after

- Bottling, Cap application, Quality assurance

- Input ingredients

- defective caps, irregular caps, sport caps, caps with no flat upper surface, cap chute

- Output ingredients

- inspected caps, caps with correct closure, production records, stored pictures

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Detection type

- Artificial vision

- Integration

- Cap chute / Arol flex cap elevator

- User interface

- User-friendly

- Production records

- Storage available

- Expandable inspections

- Yes

- Inspection Technology

- Artificial vision

- Integration

- Integrated into cap chute

- Configuration Options

- Expandable with other inspections

- Interface

- User-friendly interface

- Production Efficiency

- Increase the production efficiency

- Operation Mode

- Auto detection

- Cap Compatibility

- Various cap types including sport caps

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Inspection type

- Cap inspection

- Integration

- Cap chute / Cap elevator

- Integration into cap chute

- Yes

- Configuration availability

- Several configurations based on cap type and line

- Expandable with other inspections

- Yes