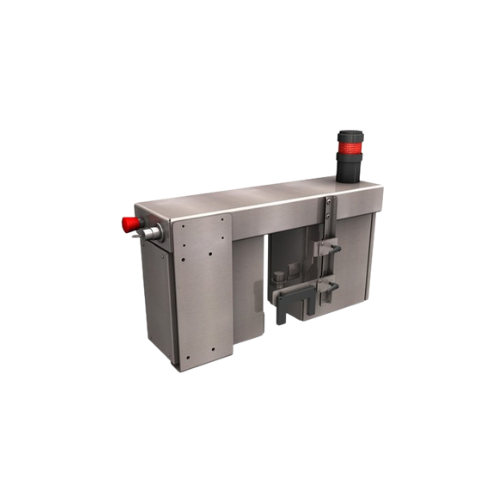

High-precision fill level checker for beverages and containers

Ensure precise fill levels and prevent product wastage by accurately inspecting containers at high speeds, making it an essential solution for maintaining quality and efficiency in your production line.

Checks Fill Levels in Containers

The Innocheck FHC Fill Height Control by KHS Group is designed to ensure accuracy and reliability in fill level inspection across a range of industries, including beverage, food, and non-food sectors. This modular system stands out with its ability to utilize high-frequency, X-ray/gamma-ray, camera, and infrared technologies to cater to specific container types and industry needs. It can inspect up to 120,000 containers per hour, making it suitable for high-speed, continuous production lines. The equipment seamlessly integrates into automated operations and offers low maintenance costs with wear-free components. Compliance with safety and operational standards is supported by KHS Group’s engineering expertise. Additionally, the system is customizable, providing options to complement various production line requirements efficiently.

Benefits

- Maximizes production efficiency with high-speed inspection of up to 120,000 containers per hour.

- Lowers maintenance costs with robust, wear-free components and simple integration.

- Provides flexible inspection solutions with multiple sensor options for precision.

- Decreases downtime through quick, modular changeovers and automation capability.

- Enhances product safety and quality by ensuring precise fill levels consistently.

- Applications

- Food, Beverages, Liquid food, Wine, Milk, Nonfood, Iced tea, Spirits, Still water, Homecare products, Juice, Soft drinks, Beer, Sparkling wine

- End products

- Liquid soap dispensers, Bottled mineral water, Tetra pak iced tea, Pasteurized milk cartons, Packaged fruit juice, Bottled sparkling wine, Chilled white wine, Household cleaning spray bottles, Carbonated cola drinks, Distilled whiskey

- Steps before

- Purification, Emulsification, Mixing

- Steps after

- Packing, Labeling, Quality Control

- Input ingredients

- glass bottles, PET bottles, glass jars, plastic containers, transparent glass, liquid beverages

- Output ingredients

- checked glass bottles, checked PET bottles, checked glass jars, checked plastic containers, accurate fill level

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Capacity

- 60, 000–120, 000 containers per hour

- Measurement Method

- High-frequency, X-ray/gamma-ray, Camera, Infrared

- Measurement Accuracy

- High-resolution images, Ionizing radiation

- Container Type

- Glass, PET bottles, Glass jars, Plastic containers

- Automation

- Modular system

- Sensitivity to Light

- Insensitive to daylight (Infrared)

- Maintenance

- Low maintenance costs

- Changeover Time

- Short changeover times

- Radiation Source

- Disconnectible (X-ray), Wear-free (Gamma-ray)

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Working mechanism

- X-ray / Gamma-ray / IR / Camera

- Integrated steps

- High-frequency / X-ray / Camera

- Inspection speed

- 60, 000 – 120, 000 containers per hour

- Maintenance requirement

- Low maintenance costs

- System flexibility

- Individually adaptable

- System design

- Modular

- Control panel type

- Touchscreen / PLC Interface

- Integration possibilities

- Intralogistics / IT Systems

- Measuring methods

- High-frequency / X-ray / Gamma-ray / Camera / Infrared

- Modular system

- Choice of modules based on container type

- Sustainability features

- Low maintenance costs / Efficient checking

- Compact design

- IR system with compact design