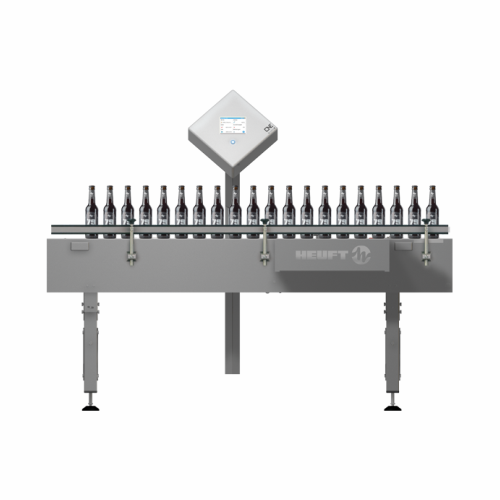

Full container inspection system

Ensure the quality and safety of your products with a compact solution that performs precise fill level, closure, and label inspections, safeguarding your production line from faults and ensuring compliance.

Inspects and Rejects Faulty Full Containers

The HEUFT ONE from HEUFT SYSTEMTECHNIK offers a compact and efficient solution for full container inspection in the beverage, food, and pharmaceutical industries. This device excels by integrating various detection modules, including fill level, closure, and label inspections, directly at the conveyor for seamless operation. Its innovative design utilizes both X-ray and high-frequency technologies to ensure accurate fill level checks, significantly reducing the false rejection rate in products like beer and carbonated drinks. The system is capable of inspecting up to 72,000 containers per hour, making it ideal for high-speed production lines. Fully automated, the HEUFT ONE features a user-friendly HEUFT NaVi interface and a flexible control unit, which can be positioned anywhere along the production line for easy operation. Additionally, optional modules are available for optical and acoustic inspections, expanding its adaptability to various production needs. With network capabilities for real-time data acquisition and remote maintenance, the HEUFT ONE ensures operational reliability and product quality. The equipment is designed to fit into tight spaces, making it an excellent choice for facilities where space is at a premium.

Benefits

- Maximizes production efficiency by inspecting up to 72,000 containers per hour.

- Saves floor space with compact design and flexible module positioning.

- Reduces product waste with precise detection technologies that lower false rejection rates.

- Enhances product quality assurance through integrated fill level, closure, and label inspections.

- Supports seamless integration into existing lines with easy-to-use controls and network capabilities.

- Applications

- Food, Beverages, Pharmaceutical products

- End products

- Beer bottles, Sauce bottles, Carbonated soft drink cans, Bottled water, Wine bottles, Tube-packed ointments, Milk cartons, Medicinal syrup bottles, Jam jars, Liquid pharmaceutical vials, Juice bottles

- Steps before

- Filling, Capping, Labeling

- Steps after

- Packing, Quality Control, Distribution

- Input ingredients

- full beverage containers, filled containers, beer bottles, carbonated soft drink containers

- Output ingredients

- fault-free beverage containers, correctly labeled containers, properly sealed containers, approved containers

- Market info

- HEUFT is known for its expertise in inline quality inspection systems and automation solutions for the food, beverage, and pharmaceutical industries, with a reputation for innovation and reliability in ensuring product safety and integrity.

- Detection type

- X-ray / HF technology

- Capacity

- Up to 72, 000 filled beverage containers per hour

- Accuracy

- Precise fill level, closure, and label check

- Automation

- Network-compatible with remote maintenance

- Space requirement

- Fits into the smallest installation space

- Detection type

- X-ray / HF technology

- Adjustability

- Freely positionable control unit

- Automation level

- Integrated sensor and analysis

- Fault rejection

- Single-segment / multi-segment

- Network capabilities

- Gigabit Ethernet / TCP/IP

- Integration type

- Compact modules with combined detection and evaluation

- Label detection

- Reflection-based sensor system

- Space efficiency

- Compact size for confined spaces

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Closure type

- Crown corks / metal closures

- Compact footprint

- Space-saving

- Machine footprint

- Fits in small installation spaces

- Control panel type

- Freely positionable control unit

- Compact footprint

- Yes

- Control panel type

- Freely positionable control unit

- Integration possibilities

- Network technologies (Gigabit Ethernet, TCP/IP)