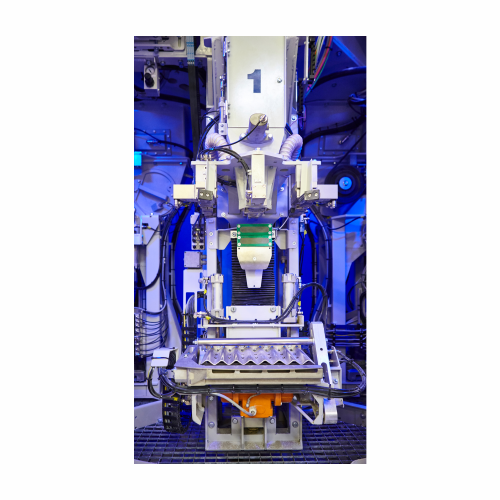

Rotating packaging system for cement and chemicals

Streamline your packaging line with a high-speed, rotating solution that ensures efficient bagging and sealing of powders, protecting your products from environmental factors while optimizing throughput.

Packs and Seals Industrial Bulk Materials

The ROTO-PACKER® from Haver & Boecker is a highly efficient rotating packaging system designed for the precise packing, filling, and sealing of industrial bulk materials. It addresses the challenges in packaging cement, building materials, and chemical products, allowing seamless integration with existing production lines. This system excels with customizable configurations to tackle diverse product properties and packaging requirements, featuring modules such as turbine and air filling technologies. With capacities ranging from 400 to 6,000 bags per hour, it offers unparalleled flexibility. The ROTO-PACKER® includes options for valve bags and FFS tubular film, ensuring a safe, clean, and weatherproof packaging solution. Enhanced with digital monitoring and remote diagnostic capabilities, it facilitates modern, automated operations. It also provides efficient energy management, thanks to its intelligent ventilation and state-of-the-art electronics. The robust construction, available with corrosion-resistant materials, underlines its durability and suitability for harsh industrial environments. Optional upgrades, like ultrasonic sealing and ROTO-LOCK® technology, enhance spillage prevention and maintenance efficiency, making it a versatile package tailored to your specific production needs.

Benefits

- Enhances operational efficiency with capacities up to 6,000 bags per hour.

- Minimizes spillage and maintenance needs with ROTO-LOCK® technology.

- Offers weatherproof packaging using ADAMS® technology for product protection.

- Reduces operational costs with automated, remote diagnostics and monitoring.

- Customizable design adapts to diverse packaging requirements, ensuring versatility.

- Applications

- Building materials, Industrial bulk materials, Chemical products, Cement

- End products

- Calcium carbonate powder packs, Cement powder, Gypsum plaster, Lime-based building materials, Bentonite clay packages, Polyethylene bags filled with cement, Mortar mix, Dry mix concrete, Polypropylene chemical bags

- Steps before

- Pre-mixing, Product Analysis, Weighing, Granulation

- Steps after

- Sealing, Palletizing, Distribution, Storage

- Input ingredients

- cement, building materials, chemical products, fine powders, mixed products

- Output ingredients

- valve bags, FFS bags, open-mouth bags, tubular film bags, ADAMS film bags

- Market info

- Haver & Boecker is renowned for its expertise in manufacturing advanced industrial ETO equipment, specializing in material handling, packing, and screening technology for industries like mining, construction, and chemicals, known for innovation and quality.

- Packaging Speed

- 400–6, 000 bags/hour

- Filling Spouts

- Up to 16

- Bag Type

- Valve / Tubular film

- Ultrasonic Sealing

- Available

- Remote and Diagnostics Capability

- Full digital equipment

- Filling Module Options

- Turbine / Air

- Weatherproof Packaging

- Fully recyclable

- Automation

- Configurable

- Monitoring System

- QUAT²RO® System

- Weighing Electronics

- MEC 4.0

- Control System

- Siemens TIA Portal

- Product Transfer Method

- Turbine / Air pressure

- Valve Bag Closure

- SEAL upgrade available

- Bag Size Adjustability

- Automatic

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Abrasion resistance

- High

- Cleanability

- Easy to clean

- Density/particle size

- Various densities and sizes

- Corrosive resistance (e.g. acids)

- Moderate

- Filling spouts

- Up to 16

- Bag capacity

- 1, 000–6, 000 bags/hour

- Bag types

- Valve bags, FFS bags

- Material compatibility

- Paper, woven PP, film

- Turbine module dimensions

- Vertical and horizontal versions

- Air module versions

- Angled or fully ventilated base plate

- Control panel type

- Siemens TIA portal control

- Seal technology

- Ultrasonic sealing

- Discharge method

- Automatic

- Control panel type

- Siemens TIA portal control

- Integration possibilities

- QUAT²RO® Monitoring/Remote/Scan/Analytics

- Bag type configuration

- Valve / Tubular film / FFS

- Sealing technology

- Ultrasonic sealing device

- Filling module type

- Turbine (T-module) / Air (L-module)

- Optional upgrades

- SEAL upgrade / RADIMAT® system

- Retrofit capability

- Yes, adaptable for performance requirements

- Automatic adjustments

- ROTO Adjust for different bag sizes