Print and verify cartons packaging systems

Streamline your packaging line with a versatile solution that prints, verifies, labels, and tamper-seals cartons, ensuring high-speed precision and secure product serialization.

Prints, Verifies, Weighs, Labels, and Seals Cartons

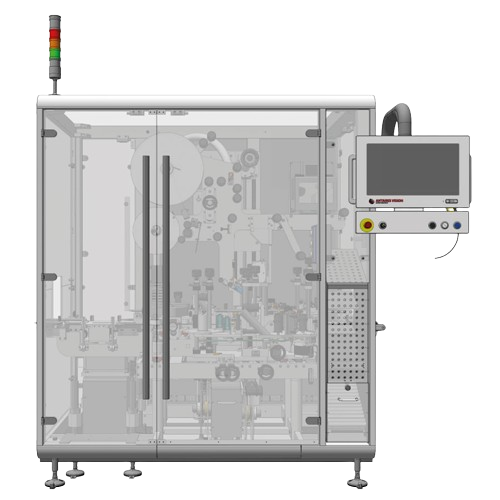

The Print & Check All-in-one (VM2800) from Antares Vision Group is a versatile solution for pharmaceutical, nutraceutical, and healthcare product packaging. This system integrates printing, verification, checkweighing, labeling, and tamper-evident sealing into a single module, ensuring data security and packaging integrity. It accommodates carton sizes of 35-120 mm (A), 15-100 mm (B), and 50-200 mm (C), with a throughput of up to 400 pcs/min, adapting to high-speed environments. Seamless integration into existing lines as a standalone or in-line unit allows pharmaceutical manufacturers and packaging companies to enhance serialization and traceability. With its robust checkweighing capabilities and precise labeling, the VM2800 ensures compliance with regulatory standards, leveraging TIJ or laser printing technology with grade A Datamatrix quality. Its ergonomic design supports efficient space utilization while offering easy maintenance and calibration. The unit is equipped with multilayer inspection systems to uphold label integrity and precision and is tailored to be compliant with industry standards for safety and performance.

Benefits

- Enhances packaging accuracy with integrated serialization and labeling, reducing error rates.

- Increases production efficiency with a high speed of up to 400 pcs/min.

- Ensures regulatory compliance with tamper-evident sealing and comprehensive data verification.

- Saves floor space with a compact, all-in-one design adaptable to existing production lines.

- Supports product diversity with adaptable printing and weighing configurations for various carton sizes.

- Applications

- Nutraceuticals, Cosmetics, Healthcare products, Packaged foods, Pharmaceuticals

- End products

- Vitamin supplement bottles, Medical device packaging, Cereal boxes, Blister packs of tablets, Skincare cream containers

- Steps before

- Carton preparation, Label preparation, Product weighing

- Steps after

- Packing, Distribution, Quality assurance testing

- Input ingredients

- cartons, labels, ink cartridges, rolls of labels

- Output ingredients

- printed cartons, verified cartons, weighed cartons, sealed cartons, labeled cartons

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line Speed

- Up to 400 pcs/min

- Line Speed with Checkweigher Enabled

- 300 pcs/min

- Working Height

- 800-1000 mm

- Standard Belt Pitch

- 150 mm

- Conveyor Length

- 1850 mm

- Standard Carton Size

- A = 35-120 mm / B = 15-100 mm / C = 50-200 mm

- Printing Technology

- TIJ / LASER

- Printable Sides with TIJ

- 3

- Printable Sides with LASER

- 2

- Printing Heads with TIJ

- Up to 4

- Printing Heads with LASER

- Up to 2

- Max Resolution

- 600 dpi

- Datamatrix Print Quality

- Grade B typical, up to Grade A

- Checkweigher Unit Standard Deviation

- 1σ 0.15 g

- Max Carton Weight

- 500 g

- Top Labelling Label Width

- Up to 60 mm

- Top Labelling External Roll Diameter

- Up to 300 mm (400 mm optional)

- Tamper Evident Label Width

- Up to 40 mm

- Tamper Evident Label Length

- Up to 30 mm

- Tamper Evident External Roll Diameter

- Up to 280 mm

- Working mechanism

- Stand-alone automatic unit

- Integrated steps

- Printing, verification, checkweighing, labeling, tamper-evident sealing

- Batch vs. continuous operation

- In-line / Off-line

- Automation level

- Single HMI control

- Line speed

- Up to 400 pcs/min

- Space optimization

- Perfect space optimization

- Configuration flexibility

- Highly flexible unit

- Working height

- 800-1000 mm

- Tamper-evident sealing capability

- Integrated

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Printing Technology

- TIJ / Laser

- Label Application Options

- Top and Bottom / Same Side / Alternated

- Machine footprint

- Conveyor length

- Working height

- 800-1000 mm

- Standard carton size

- A = 35-120 mm, B = 15-100 mm, C = 50-200 mm

- Control panel integration

- Single HMI to manage settings

- Integration Possibilities

- Standalone module, in-line or off-line

- Printing Technology

- TIJ or laser printer

- Number of Printable Sides

- Up to 3 carton sides

- Thermal Transfer Print Engine

- Optional

- Label Application Options

- Top and bottom according to carton flaps, same side or alternated

- Carton Size

- Customizable within defined range