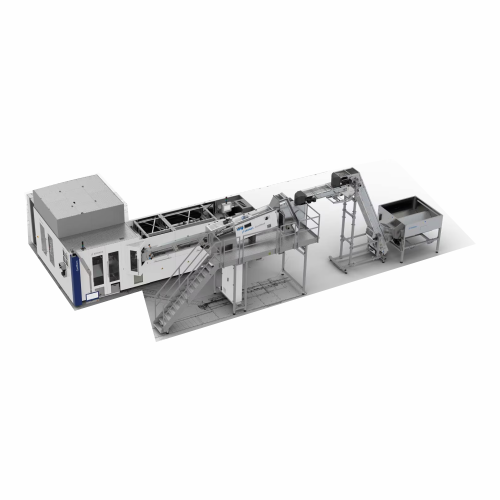

Preform and container inspection system

Ensure only flawless preforms and bottles continue in your production line with an integrated inspection system that rejects any defects, maintaining top-tier bottle quality and protecting downstream processes from potential malfunctions.

Inspects and Rejects Faulty PET Containers

The PET-View inspection system from Krones provides precise quality assurance for PET bottle producers and beverage manufacturers by systematically inspecting and rejecting defective preforms and containers. This system, integrated directly into the blow moulder, ensures a seamless production flow. It evaluates a wide array of criteria such as sealing surface integrity, wall thickness, and material distribution, making it equally effective for both virgin PET and recycled materials. Operating via a user-friendly touch-screen interface, it supports continuous, high-speed, automated processes while protecting the blow moulder from malfunctions. PET-View is especially valued in the food and beverage, packaging, and recycling sectors for its reliability and efficiency in maintaining bottle quality.

Benefits

- Ensures consistent bottle quality by rejecting faulty preforms and containers, preventing production defects.

- Minimizes production downtime by integrating seamlessly into continuous operations.

- Protects the blow moulder from potential malfunctions and disruptions.

- Supports sustainable packaging with the ability to inspect up to 100% recycled PET.

- Enhances operational efficiency with intuitive touch-screen controls.

- Applications

- Rigid plastic packaging, Bottled water, Pet containers, Soft drinks packaging, Home care product containers, Beverage bottles, Juice bottles, Milk-based drinks containers, Bottled spirits

- End products

- Steps before

- Preform production, Preform transportation, Preform storage

- Steps after

- Bottle filling, Bottle capping, Bottle labeling, Bottle packaging

- Input ingredients

- preforms, virgin material, recyclate, faultless preforms

- Output ingredients

- faultlessly blow-moulded bottles, PET bottles

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Inspection Criteria

- 360° Side wall, Contamination, Banana shape, Trapped air, Length of the gate, Length and diameter, Sealing surface, Ovality, Damage, Opaque faults

- Material Compatibility

- Virgin and rPET

- Automation

- Operation via the blow moulder’s touch-screen panel

- Process Integration

- Integration into the blow moulder

- Rejection Positions

- A, B, C, D

- Inspection type

- 360° side wall, sealing surface, base inspection

- Integration

- Into the blow moulder

- Operation control

- Touch-screen panel

- Fault rejection

- Systematic rejection at specified positions

- Material compatibility

- Virgin and rPET

- Recycled PET (rPET)

- Up to 100% recyclate

- Shape compatibility

- Banana shape, Ovality

- Container type

- PET/bottles

- Integration

- Integrated into blow moulder

- Control panel type

- Touch-screen panel

- Inspection criteria

- 360° Side wall, Sealing surface, Ovality, etc.

- Control panel type

- Touch-screen panel