Closure inspection system for beverage caps

Ensure complete closure integrity in high-speed beverage production lines with this advanced inspection system, meticulously engineered to detect and eject defective caps and closures before they reach the end consumer, safeguarding product safety and quality.

Inspects and Ejects Faulty Beverage Closures

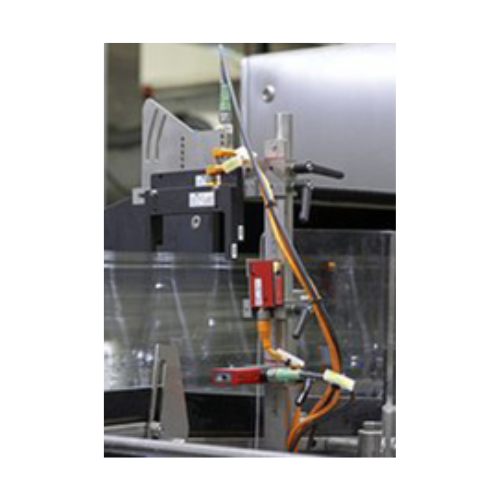

The Innocheck CPC Closure Inspection System from KHS Group is expertly designed to ensure the integrity of beverage packaging across various closure types. This system stands out for its use of rugged sensor technology, including light scanners and metal proximity switches, which allows for precise detection of defective or missing closures on up to 120,000 containers per hour. Designed for integration into high-speed, continuous production lines, this system is ideal for beverage manufacturers producing soda, beer, juice, and more. Its automated ejection mechanism immediately removes non-compliant containers, preventing contamination and ensuring product quality. With minimal maintenance requirements and compatibility with other KHS equipment, the Innocheck CPC enhances operational efficiency and supports seamless process integration. Available for use in beverage, food, and non-food industries, it offers high product flexibility and is supported by KHS’s engineering expertise to meet specific production needs.

Benefits

- Increases operational efficiency by inspecting up to 120,000 containers per hour.

- Enhances product safety by ensuring proper closure integrity, preventing contamination.

- Reduces maintenance costs with durable sensor technology, minimizing service intervals.

- Seamlessly integrates with existing production lines for streamlined operations.

- Supports diverse packaging needs with compatibility across various closure types.

- Applications

- Crown corks, Beverage caps, Sports drink caps, Can lids, Swing stoppers, Corks, Beverage closures, Plastic caps, Metal caps

- End products

- Beer bottles, Sports drink bottles, Metal soda cans, Wine bottles, Soda bottles, Craft beer bottles, Juice bottles, Champagne bottles, Aluminum beer cans

- Steps before

- Container filling, Beverage production, Cap placement

- Steps after

- Quality assurance, Packing, Distribution

- Input ingredients

- beverage containers, plastic caps, metal caps, sports drink caps, corks, crown corks, swing stoppers, can lids

- Output ingredients

- inspected containers, containers with verified closures, ejected containers without closures

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Speed

- up to 120, 000 containers per hour

- Closure Inspection Type

- Light scanners, light barriers, metal proximity switches

- Container Closure Types

- Plastic and metal caps, sports drink caps, corks, crown corks, swing stoppers, can lids

- Rugged Sensor Technology

- Proven track record

- Product Ejection System

- Immediate ejection for containers without closures

- Maintenance Requirement

- Reduced to a minimum

- Inspection speed

- Up to 120, 000 containers per hour

- Sensor technology

- Light scanners, light barriers, metal proximity switches

- Closure types compatibility

- Plastic caps, metal caps, sports drink caps, corks, crown corks, swing stoppers, can lids

- Plastic cap compatibility

- Yes

- Metal cap compatibility

- Yes

- Sports drink cap compatibility

- Yes

- Cork compatibility

- Yes

- Crown cork compatibility

- Yes

- Swing stopper compatibility

- Yes

- Can lid compatibility

- Yes

- Machine Footprint

- Compact Design

- Container Compatibility

- Plastic, Metal Caps, Corks

- Inspection System

- Light Scanners, Light Barriers, Metal Proximity Switches

- Sensor Technology

- Rugged Sensors

- Deployment Method

- Inline Systems

- Operation Speed

- Up to 120, 000 containers per hour

- Control panel type

- Touchscreen / Manual

- Sensor integration

- Light scanner / Metal proximity switch

- System integration

- With fill level inspection systems

- Container size flexibility

- Various types including glass and PET

- Closure type compatibility

- Plastic caps, metal caps, corks, crown corks