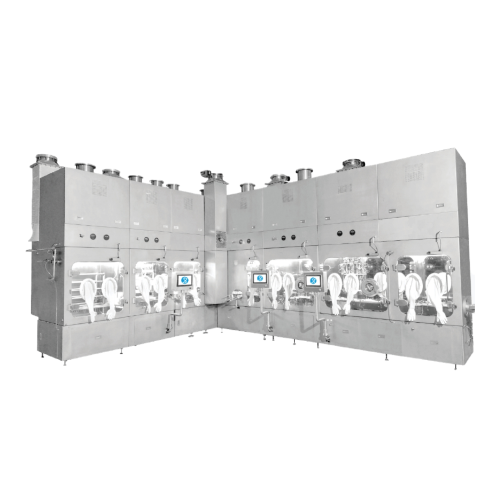

Ampoule filling and sealing line

Streamline your ampoule production with an integrated solution that expertly handles everything from washing to labeling, ensuring precision and efficiency at every step.

Processes and Packages Ampoules Continuously

The integrated ampoule production line from Snowbell Machines offers a comprehensive solution for pharmaceutical manufacturers, handling the entire process from washing to labeling. This system leverages servo control technology to ensure precision and complies with 21 CFR Part 11, enhancing traceability and data integrity. Designed for liquid formulations, it seamlessly integrates processes such as washing, sterilizing, filling, sealing, inspection, and labeling of ampoules, capable of high-speed, continuous operation. The system’s automation, facilitated by a GAMP and SCADA system, allows for streamlined integration into existing production lines, reducing manual intervention and improving efficiency. Ideal for pharmaceutical and biotech industries, this production line ensures compliance with stringent quality standards, offering robust performance in packaging, cleaning, and final conditioning departments.

Benefits

- Enhances operational efficiency with continuous, high-speed processing.

- Ensures regulatory compliance and data integrity through 21 CFR Part 11 adherence.

- Streamlines production by integrating multiple processes into a single, automated line.

- Minimizes contamination risk with controlled, enclosed operations.

- Adapts to existing systems, reducing integration time and costs.

- Applications

- Ampoules, Liquid formulations, Pharmaceuticals

- End products

- Steps before

- Washing

- Steps after

- Sterilizing, Filling, Sealing, Inspection, Labelling

- Input ingredients

- ampoules, pharmaceutical substances

- Output ingredients

- washed ampoules, sterilized ampoules, filled ampoules, sealed ampoules, inspected ampoules, labelled ampoules

- Market info

- Automation

- SCADA system

- Compliance

- 21 CFR Part 11

- Control system

- Servo control system

- Integrated steps

- Washing, Sterilizing, Filling, Sealing, Inspection, Labelling

- Automation level

- Servo control system

- Compliance systems

- 21 CFR Part 11 / GAMP / SCADA

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Servo control system

- Discharge method

- Sealing