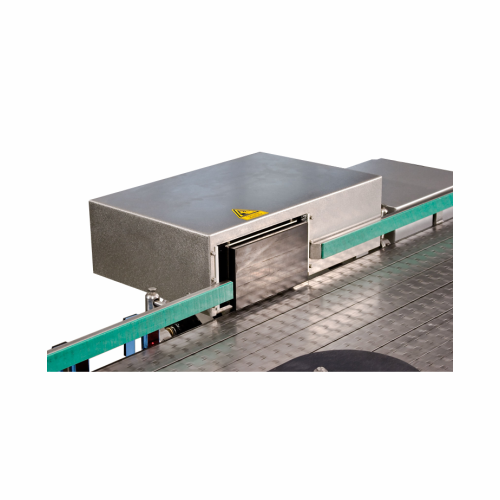

Industrial case rejector for faulty packaging

Ensure product integrity by smoothly removing faulty cases from your production line, optimizing both precision and careful handling without halting high-speed operations.

Rejects and Sorts Faulty Packaging

The HEUFT case rejector system, a precision engineering solution from HEUFT SYSTEMTECHNIK GmbH, excels in efficiently managing faulty or non-brand packaging on high-speed production lines. This system’s unique load-dependent control adapts rejection impact to case weight, ensuring precise removal and distribution without damaging the packaging. Its adaptability spans diverse applications, handling beverage crates and pharmaceutical vials to food trays and pet food packages, maintaining brand integrity across the board. Each component, from the HEUFTxcase to the space-saving HEUFTmaxi-laner, integrates seamlessly into existing conveyor systems, enhancing throughput and operational efficiency. Designed with continuous, automated operation in mind, it leverages HEUFT’s robust mechanical engineering and intelligent control systems to reduce energy usage and streamline processes. Compliance with industry standards guarantees its reliability and safety, while options for customization ensure it meets specific production needs.

Benefits

- Enhances brand integrity by reliably removing non-brand and defective cases.

- Increases operational efficiency with minimal system downtime.

- Adapts seamlessly to different case weights, preserving packaging integrity.

- Supports high-speed production environments with continuous automated operation.

- Integrates effortlessly into existing conveyor systems, optimizing process flow.

- Applications

- Food, Beverage, Trays, Pharma, Shrink wrap packages, Crates, Cardboard boxes

- End products

- Bagged snacks, Ready-made meals, Dairy crates, Juice cartons, Pet food packages, Beer cans, Soda bottles, Pharmaceutical pill bottles, Wine bottle boxes, Frozen food trays, Vaccine vials

- Steps before

- Inspection, Sorting, Container filling, Labeling

- Steps after

- Packing, Distribution, Final inspection, Shipping

- Input ingredients

- faulty cases, non-brand cases, damaged trays, empty cases, half-full cases, completely full cases, outer packaging, crates, cardboard boxes, trays, shrink wrap packages

- Output ingredients

- rejected faulty cases, rejected non-brand cases, rejected damaged trays, rejected empty cases, rejected half-full cases, rejected completely full cases, distributed trays, distributed cases, rejected crates, rejected cardboard boxes, rejected shrink wrap packages

- Market info

- HEUFT is known for its expertise in inline quality inspection systems and automation solutions for the food, beverage, and pharmaceutical industries, with a reputation for innovation and reliability in ensuring product safety and integrity.

- Rejection method

- Discharging, rejecting and distributing

- Control system

- Load-dependent control system

- Rejection impact force adaptation

- Adapts to the weight of each individual case

- Rejection fingers

- Three on a sledge under the roller conveyor

- Parallel conveyor chains

- Available for empty, half-full, or full cases

- Lane distribution

- Three lanes

- Changeover necessity

- No mechanical changeover required

- Automation level

- Load-dependent control system

- Batch vs. continuous operation

- Continuous

- Rejection method

- Case/tray rejection with sledge and rejection fingers

- Load adaptation

- Force adapts to weight of cases/trays

- Distributing capability

- Onto several lanes

- Space-saving design

- Compact system installed above conveyor

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Package type

- Crates / Cardboard boxes / Trays / Shrink wrap packages

- Compact footprint

- Space-saving design with conveyor integration

- Control panel type

- Load-dependent control system

- Discharge method

- Rejection using rejection fingers or segments

- Machine footprint

- Installed directly above conveyor

- Basket,cone,or tank shape and size

- N/A

- Load-dependent control system

- Adapts rejection force to case weight

- Rejection distance control

- Equal rejection distance for all weights

- Lane distribution capability

- Three-lane distribution possible