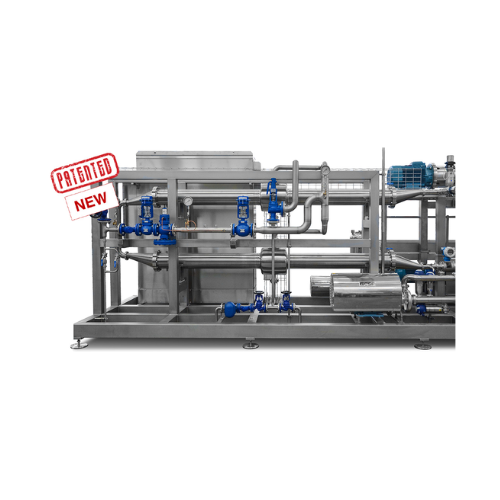

Cold extraction deaeration system for fruit and vegetable purees

Achieve superior puree quality with our system that ensures optimal cold extraction and deaeration, maintaining natural flavors and nutrients while enabling continuous high-speed processing and efficient thermal shock deactivation.

Extracts and Deactivates Purees for Food Processing

The ULTRA Series Turbo Extractors from Bertocchi Srl offer a sophisticated solution for fruit and vegetable processing, specializing in cold extraction and rapid enzymatic deactivation. These machines revolutionize puree production by incorporating a thermal shock deactivation process, ensuring product stability and nutritional retention. Ideal for applications in baby food, smoothies, and concentrates, they process up to 24 tons per hour with a seamless integration into existing production lines. The system boasts a compact design for continuous, high-speed operations with flexible automation options, allowing effortless control via a PLC interface. Material options emphasize durability and hygiene, meeting stringent food safety standards. Furthermore, these extractors are engineered for easy maintenance with an integrated CIP system and supported by comprehensive customization services to meet specific processing needs.

Benefits

- Increases product quality by preserving nutritional content through cold extraction and thermal shock deactivation.

- Enhances operational efficiency with continuous high-speed processing capability.

- Saves energy with optimized motor control for reduced power consumption.

- Ensures food safety compliance with hygienic design and CIP system.

- Adaptable to various processing environments with customizable configurations and material options.

- Applications

- Smoothies, Sauces, Plant-based purees, Fruit purees, Nectars, Concentrates, Baby food, Vegetable purees

- End products

- Aseptic fruit puree for retail, Stone fruit baby food, Peach puree concentrate, Apricot nectar, Red fruit smoothie blends, Apple puree for infants, Tropical fruit sauce, Deactivated vegetable soup base, Multi-fruit plant-based puree, Pear puree for toddlers

- Steps before

- Chopping, Destoning, Sorting, Washing

- Steps after

- Packing, Aseptic Filling, Concentration, Sterilization

- Input ingredients

- fruits, vegetables, whole fruits, chopped fruits, destoned fruits, apples, pears, destoned peaches, destoned apricots, grapes, red fruits, wild fruits, tropical fruits, low consistency vegetables

- Output ingredients

- deactivated fruit puree, deactivated vegetable puree, concentrate, single-strength puree, hot packed puree, aseptic puree, baby foods, nectars

- Market info

- Bertocchi is known for manufacturing engineered-to-order industrial equipment, specializing in custom process solutions for the food and beverage industry. They have a strong reputation for innovation, quality, and reliability in producing machinery tailored to customer specifications.

- Capacity

- 1000 kg/h to 24 t/h

- Process Type

- Cold extraction and cold deaeration

- Deactivation Method

- Ultrarapid deactivation by thermal shocking

- Number of Model Sizes

- 10

- Product Type Processed

- Fruits and vegetables

- Automation level

- Enzymatic Deactivation Circuit

- Batch vs. continuous operation

- Continuous

- Product Processed State

- Whole, Chopped, or Destoned

- Recirculation

- Hot Product through Cold Turbo Extractor

- Biological compatibility

- Compatible with fruits and vegetables

- Corrosive resistance

- High, suitable for processing acidic fruits

- Cleanability

- Designed for easy cleaning with CIP

- Viscosity

- Varies

- Enzymatic deactivation sensitivity

- High

- Machine footprint

- Varies by model size

- Tank shape

- Cold Turbo Extractor design

- Feed method

- Suitable for whole, chopped, or destoned fruits

- Discharge method

- Screen outlet discharge

- Control panel type

- PLC / HMI

- Integration possibilities

- With existing production line

- Compact footprint

- Space-saving design

- Material options

- Stainless steel / Food-grade materials

- Capacity options

- 1000 kg/h to 24 t/h