Making Jam

Find innovative production technology for making jam and connect directly with world-leading specialists

The kitchen toaster may be the first appliance that a jam jar brings to mind. But turning fruit into the classic spreadable involves an entire line of jam processing equipment. The meticulous preparation for high-capacity jam manufacturing puts paid to the old idiom 'money for jam'.

Select your jam process

Tell us about your production challenge

Giving your jam the right texture with a vacuum cooker

The secret to a spreadable jam is a balanced combination of sugars, acids, and pectin. High methoxyl pectin is added to give your finished product the proper structure and fluidity.

HM pectin needs to boil for around one minute at 105°C in the vacuum cooker to form a mesh with sugar and acid. However, uneven heat distribution or overcooking the mix causes your pectin-sugar-acid matrix to come apart, resulting in runny jams.

Why your low-calorie jams are more fluid

Pectic substances with low methoxyl properties (LMP) can form a jam structure without bonding with sugars and acids. While LMP is ideal for jams with reduced sugar content, the calcium salts added to the mixture to create the gelling structure develop into a more viscous product.

At the same time, LMP pectin retains better stability in low pH foods such as grapefruit or blueberry than HM pectin. The gelation of LMP substances is also more cohesive at higher temperatures.

High pressure processing technology to protect your jam from spoilage

The fruit pulp in a jam is a magnet for microorganisms, and bacteria quickly attack heat-treated jars once opened. High pressure processing (HPP) is emerging as a viable preservation method to inactivate pathogens such as listeria, E. coli, and salmonella.

Microbiological studies show that applying HPP techniques extends the shelf life of products at room temperature by three months. More importantly, fruit jams subjected to 400-600 MPa registered no loss in texture quality or color.

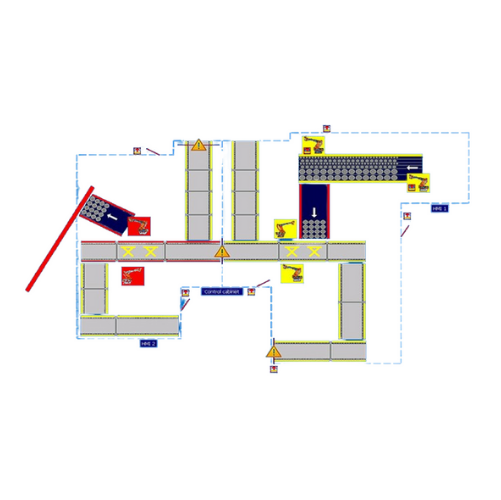

Processing steps involved in jam making

Which jam technology do you need?

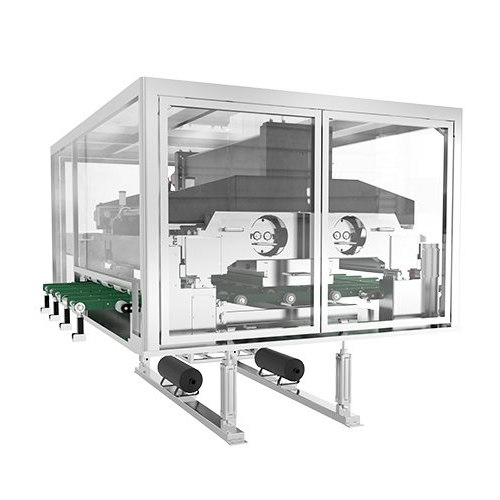

Layer cake production system

Effortlessly streamline your bakery production with a system designed for precise layering and ...

Volumetric piston depositors for cake and pie fillings

Achieve precise depositing and gentle handling of varied doughs an...

Cakes and pastry fill injector

Achieve precise and efficient filling of a variety of bakery products, minimizing waste and d...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Melting and mixing kettles for chocolate production

Achieve consistent melting and mixing of chocolates, butter, and jams...

Rapid chocolate and fat melting system

Optimize your confectionery production with an efficient solution designed to rapidl...

Chocolate melter for large quantities

Efficiently melt and maintain the temperature of substantial chocolate quantities wit...

Chocolate melting and mixing kettle for small-scale production

Streamline your confectionery production with a compact k...

Powder and liquid mixing system for food and life sciences

Achieve rapid and homogeneous dissolution of large quantities...

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

Clean-in-place system for industrial cleaning needs

Optimize your production efficiency with a system that seamlessly int...

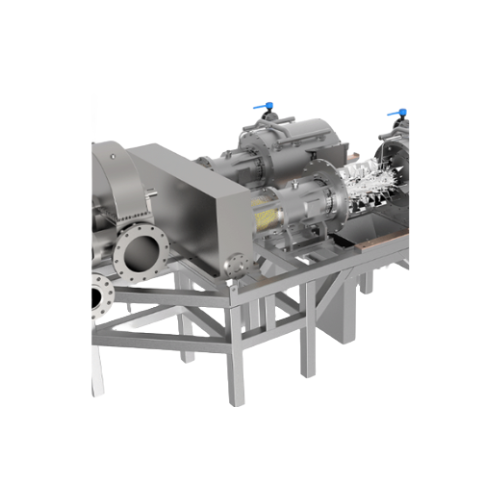

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Automated capsule packaging system

Streamline your high-speed packaging operations with a system designed for precision fil...

Lab-scale water bath blending vessel for product preparation

Ensure consistent flavor and quality across diverse small-s...

Co-extruder for filled sweet and savoury products

Effortlessly create a variety of filled sweet and savoury products, fro...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Industrial mixer for baby food and dairy production

Optimize your production line efficiency with a versatile mixing solu...

Industrial melting tank for diverse manufacturing applications

Optimize your production with this versatile melting tank...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

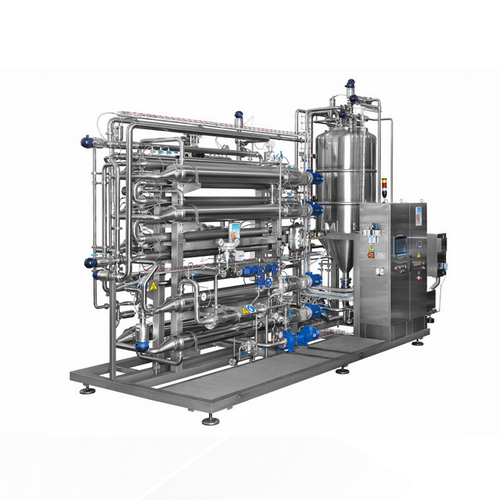

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

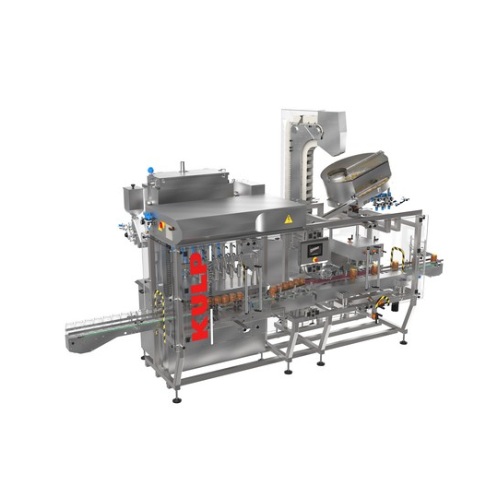

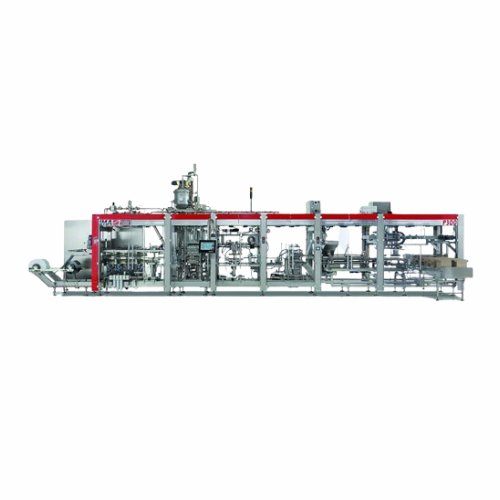

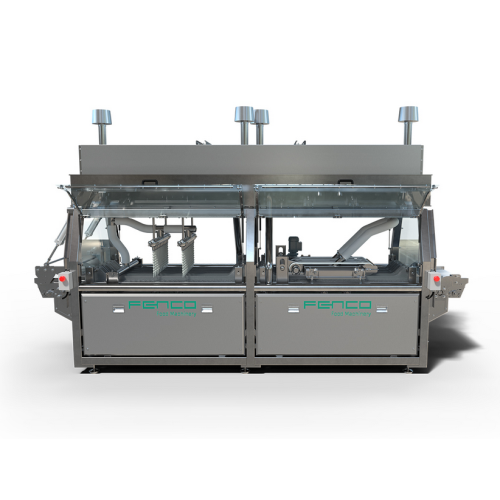

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

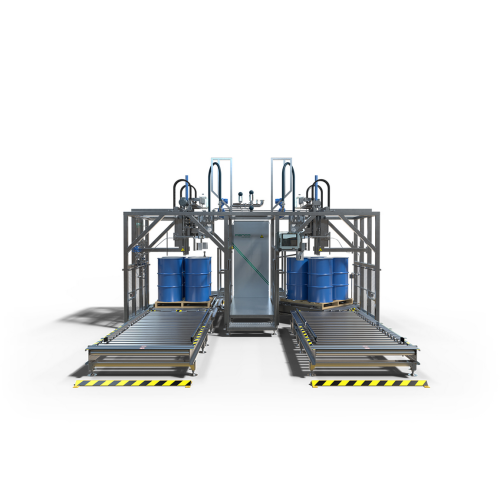

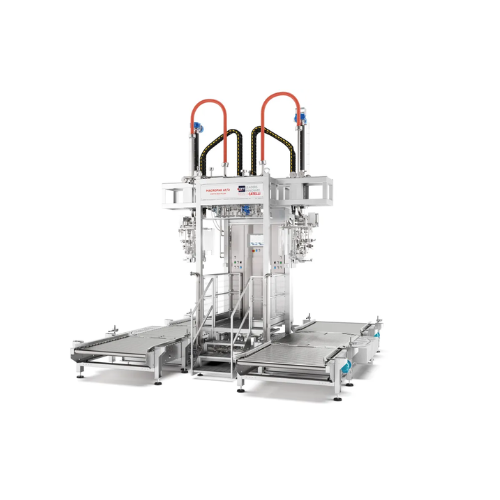

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

4 head sealing system for plastic and glass jars

Achieve precision sealing for jars of various materials with this high-sp...

Continuous inline capping system

Perfect for high-speed operations, this system ensures precise capping of diverse container...

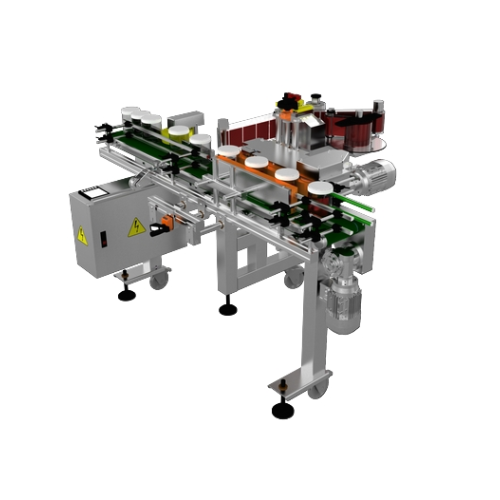

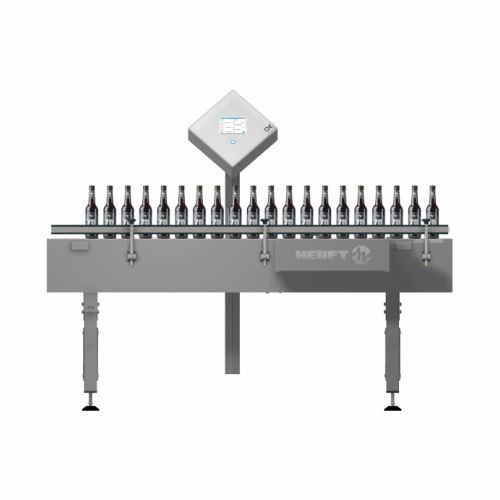

Container labeling for jars and bottles

Achieve precise labeling for diverse container shapes, from jars to square bottles,...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

Jam kettle for preserve and marmalade production

Ensure consistent flavor and texture in your jams and marmalades with pre...

Food dosing systems for industrial applications

Optimize your food production efficiency by minimizing waste with precisio...

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

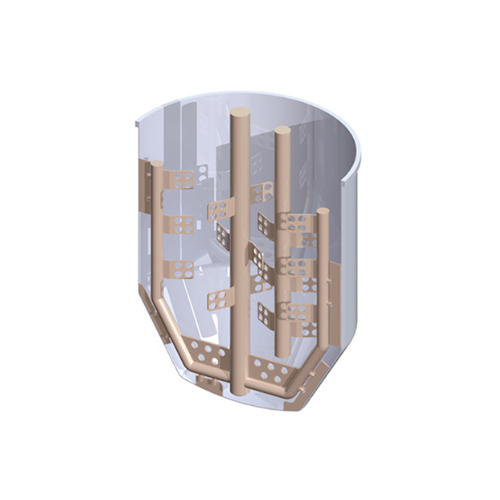

Agitators for mixing tanks

Optimize mixing operations with versatile agitators designed for various viscosities and fluid ty...

Industrial vacuum cooker for sauces

Enhance your sauce and jam production with an industrial vacuum cooker that offers cutt...

Industrial vacuum kettle for sauce production

Achieve optimal flavor retention and nutrient preservation with an industria...

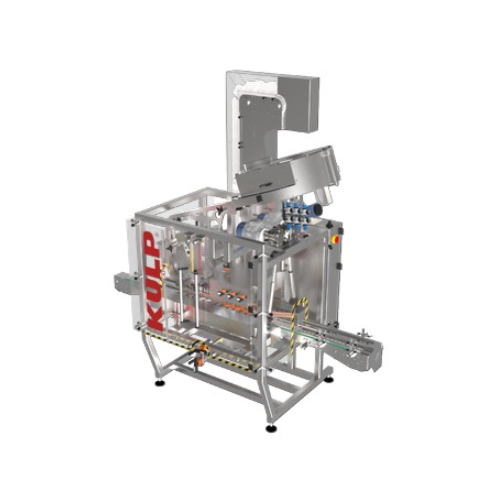

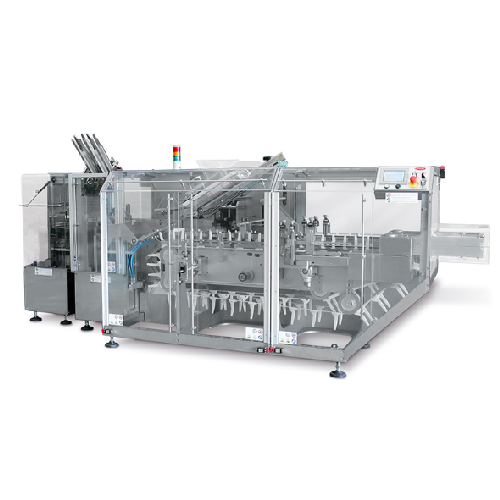

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

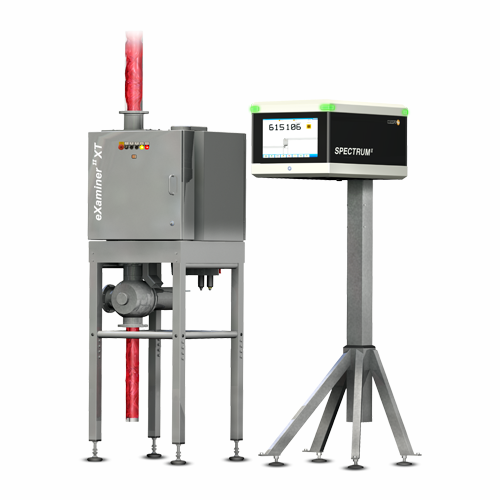

Pipeline inspection for liquid and paste-like products

Ensure your liquid and paste-like products are free from foreign o...

Semi-modular labeller for precise beverage bottle labelling

Achieve millimeter-precision bottle labelling with seamless ...

Versatile labeller for food industry

Enhance your packaging line with a versatile labelling machine capable of applying wra...

Foreign object inspection for full containers

Detect and remove minute foreign objects from liquid and paste-like products...

Full container inspection system

Ensure the quality and safety of your products with a compact solution that performs precis...

Wafer sheet cream application system

Achieve precision in cream application with high-capacity, continuous film spreading, ...

Pipeline metal detection for pumpable products

Ensure safety and quality by detecting and rejecting metal contaminants in ...

Stainless steel skids for food process integration

Optimize your production process with compact stainless steel skids th...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Pulper finisher for tomato and cold extraction

Enhance your production line efficiency with a pulper finisher designed to ...

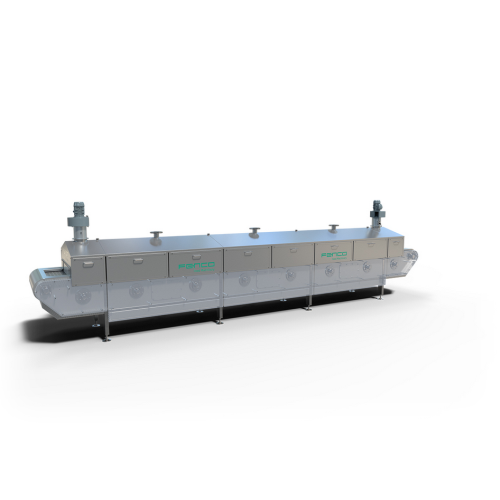

Industrial tunnel pasteurizer for rigid containers

Ensure consistent product quality and safety with a tunnel pasteurizer...

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

Efficient drying solution for food packaging pouches

Optimize your packaging line with precise moisture control, ensuring...

Industrial evaporators for multi-product processing

Optimize your production line with customized evaporators designed fo...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

Cell disintegration measurement tool for food products

Ensure precise measurement of cell disintegration across food prod...

Fruit processing system for jams and marmalades

Optimize your fruit-based product manufacturing with equipment designed fo...

Dual-purpose biscuit and jam depositing system

Enhance your production line with a versatile solution that seamlessly depo...

Gear or piston filling-dosing equipment for creamy and thick foods

Efficiently dose and fill dense and creamy products ...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

Combination cooker-dosing kit for food packaging

Optimize your small-scale food production with seamless cooking-to-packag...

Industrial cooker for food processing

Enhance your production line with versatile cooking solutions designed for precise te...

Electric cooker for preserved food preparation

Efficiently streamline your preserved food production with a multifunction ...

Industrial low temperature freeze dryer for high sugar or acid content products

For processing challenging high sugar ...

Tunnel for thermal treatment of packaged foods and beverages

Optimize your thermal processing with this customizable tun...

Leaf vegetable sorting and cooling system

Ensure optimal freshness and extended shelf life for leaf vegetables with precis...

Industrial cooking kettles for food processing

Optimize your production with versatile cooking kettles designed to handle ...

Robotic palletizer for material handling

Experience seamless and efficient palletizing with advanced robotic solutions desi...

Precision size grader for tomatoes and round fruits

Ensure precise grading and sorting of tomatoes and round fruits to op...

Robotic case packers for bags and pouches

Efficiently pack a variety of bagged and pouched products with precision handlin...

Robotic handling systems for beverage containers and bins

Streamline your container handling with precision-engineered r...

Industrial can seamers for food and beverage packaging

Streamline your canning process with precision seaming solutions d...

Industrial spiral freezing system

Optimize your food processing line with a reliable spiral system, designed to efficiently...

Sterilizers and pasteurizers for industrial food processing

Optimize thermal processing for viscous foods and beverages ...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

Batch retorts for food sterilization and pasteurization

Achieve optimal sterilization and pasteurization of packaged food...

Tomato processing crushing mill

Optimize your production line with efficient chopping and refining, ensuring uniformity and ...

Robotic depalletizers for bins

Efficiently optimize your warehouse space while ensuring precise and adaptable material handl...

Enzymatic inactivation system for fruits and vegetables

Achieve optimal product quality by maintaining vivid color, robus...

Energy efficient tomato evaporator

Achieve up to 98% steam savings in your evaporation process while ensuring minimal CO2 e...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

High-speed wet glue labelling system

Ensure precise labelling on diverse bottle types with our versatile rotary labelling s...

Vibratory rotary filler for accurate filling in food packaging

Achieve precise and efficient filling of diverse solid pr...

Lidding system for cups and trays

Enhance your packaging line with precise, space-saving lidding technology, ideal for seal...

Sleeving machine for product presentation

Enhance your product’s appeal with precise, continuous sleeving and wrappi...

Dosing unit for semi-automatic filling and packaging extension

Streamline your filling operations with this dosing unit,...

Batch cooker for confectioneries

Achieve consistent texture and flavor in every batch with this precision-driven cooker desi...

Defreezer for fruit and vegetable preparations

Optimize your fruit and vegetable processing with a versatile defreezer tha...

Horizontal evaporation bowl for fruit jams and purees

Optimize thermal exchange and preserve product integrity during jam...

Hammer pulping system for fruit and vegetable processing

Optimize your fruit and vegetable pulping process with a high-sp...

Pressure equipment directive (ped) compliant tanks

Achieve precise pressure regulation and safety with tanks designed to ...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

Shelling mill for Iqf and frozen fruit lumps

Effortlessly process frozen fruit and vegetable conglomerations into shelled ...

Shelling mill for Iqf and frozen lumps

Precision-engineered for the seamless transition from frozen state to process-ready ...

Turbo extractor for puree and concentrate production

Enhance your puree and concentrate production with a turbo extractor...

Belt blancher for vegetables

Optimize your vegetable processing with efficient blanching and cooking, ensuring reduced treat...

Fruit and vegetable washing solution with agitating action

Experience efficient dirt removal and product agitation for f...

Horizontal mixer for creams

Achieve optimal and uniform mixing of creams, pasty products, and powders with advanced horizont...

Sterile cooling system for fruit preparations

For manufacturers seeking aseptic conditions, this cooling system ensures ra...

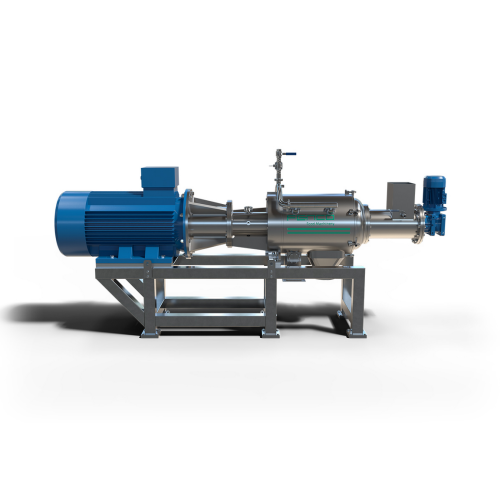

Scraped surface sterilizer for high viscosity liquid products

Optimize your production of high viscosity liquids with a ...

Apple processing equipment for juice and puree production

Efficiently process apples and pears into high-quality juice a...

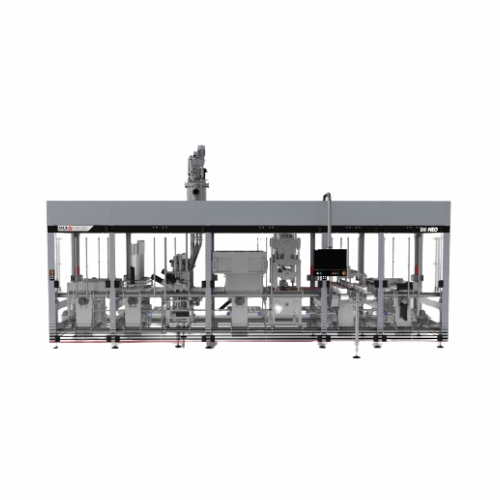

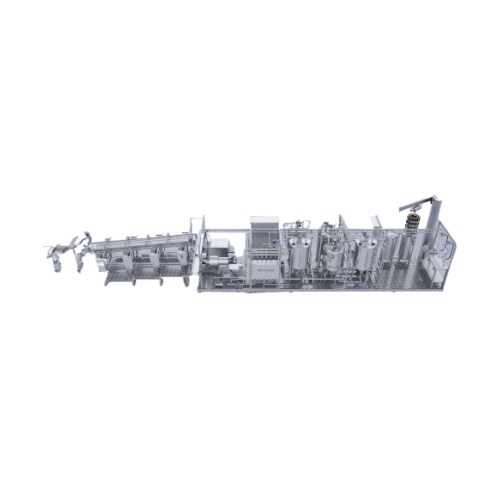

Industrial jam processing line for fresh fruit or puree

Streamline your jam production with a versatile line capable of p...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Industrial liquefying and crunching solution for frozen fruits and vegetables

Efficiently transform frozen produce int...

Turbo extractor for cold extraction of fruit and vegetable purees

Achieve high-yield, efficient cold extraction of frui...

Frozen extraction turbo extractor for fruit and vegetable purees

Efficiently transform frozen fruits and vegetables into...

Cold extraction system for fruits and vegetables puree

Optimize your fruit and vegetable puree production with a versatil...

Crunching and dosing solution for frozen fruits and vegetables

Streamline your processing line with a versatile system d...

Cold extraction turbo extractor for fruit and vegetable puree

Optimize your processing line with continuous cold extract...

Industrial glaze sprayer for high-volume bakery production

Enhance product appeal and extend shelf life with precise gla...

Pneumatic dosing system for dense and semi-dense products

Easily handle dense and semi-dense products with precision dos...

Aseptic filler for bag in drum or box

Enhance product shelf life and maintain quality without preservatives by employing as...

Checkweighers with chain conveyors for diverse package types

Optimize your production line with precision weighing, acco...

Dual lane x-ray inspection system for cosmetics

Optimize your production line with dual-lane x-ray technology that ensures...

Spiral conveyor for individual bottles and cans

Streamline your production line’s space and layout with a compact co...

Automatic bottle cold glue labeling solution

Achieve precise labeling for diverse container types, enhancing your producti...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

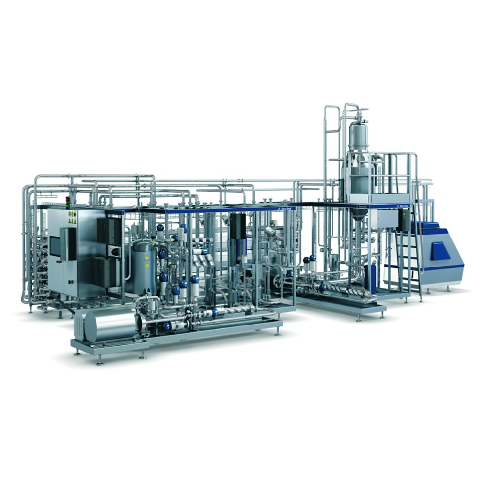

Aseptic vacuum cooker-cooler for jams and marmalade

Ensure your fruit-based products retain vibrant color and taste while...

Vacuum cooker-cooler for jams and sauces

Optimize your food production with a vacuum cooker-cooler that enhances flavor whi...

Semi-automatic piston injector for bakery products

Enhance your bakery production with precise delivery of a wide range o...

High-viscosity mass depositor

Efficiently deposit high-viscosity masses like caramel and jam with precision, while the integ...

Basket tracking system for automated batch retort systems

Efficiently manage and monitor your batch processing with a sy...

Ohmic heat exchanger for high viscosity foods

Optimize the thermal processing of heat-sensitive foods with precise ohmic h...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Sandwich and biscuit depositing system

Achieve high-capacity sandwich and biscuit production while maintaining precision wi...

Modular and combined labeling machines for bottling

Achieve high-speed labeling with unmatched flexibility, combining mul...

Rotary tampers for metal and glass containers

Optimize your food production line with high-speed rotary tampers, designed ...

Integrated filling and capping system for food and soft drinks

Streamline your bottling operations with an integrated sy...

Complete filling and closing line for food containers

Optimize your production line with a versatile solution that ensure...

Rotary piston fillers for pumpable products

Optimize high-speed production lines with precision filling for diverse liquid...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

X-ray scanner for sealed container inspection

Ensure the integrity and quality of sealed containers while seamlessly integ...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Industrial food portioning system

Optimize your production flow with precision portioning equipment designed to handle a di...

Compact food depositor for direct container use

Streamline your depositing process with a versatile solution that handles ...

Tabletop food depositor for portion control

Streamline your food production with precise portion control, reducing waste a...

Tubular pasteurizers for fruit pulp and tomato concentrate

Enhance your fruit and tomato product preservation with effic...

Tunnel pasteurizers for high and low viscosity fruit juices

Optimize your production with versatile tunnel pasteurizers,...

Forced circulation fruit juice concentrator

Optimize your fruit juice production with advanced forced circulation technolo...

High pressure aseptic sterilizer for tomato paste

Ensure your tomato paste achieves optimal safety and quality with a hig...

Multi-fruit extraction line for mango, guava, and passion fruit juice

Optimize your fruit processing with high-yield ex...

Small-scale fruit processing line for juices and sauces

Streamline your small-scale production with a versatile line that...

Multifruit processing line for wholemeal pulps and juices

Optimize your fruit processing capabilities with a skid-based ...

Multifruit processing line for tropical and temperate fruits

Optimize your fruit processing operations with a versatile ...

Nectar formulation line for fruit juices

Optimize your fruit-based product lines with a seamless process that integrates hi...

Pineapple juice extraction line

Streamline your pineapple processing with a complete solution designed to efficiently transf...

Tomato paste production line

Maximize tomato yield and flavor retention with this robust processing line designed to ensure ...

Aseptic filler for fruit juice and dairy products

Ensure sterile, high-speed filling of liquids and creams with precision...

Aseptic sterilizers for fruit concentrates and pulp

Optimize your fruit processing by maintaining product quality and she...

Banana purée production line

Maintain banana pulp quality by processing in a nitrogen atmosphere, ensuring fresh, oxidation-...

Batch evaporators for fruit juice and tomato concentration

Achieve high-quality fruit and tomato concentrates while pres...

Aseptic storage tanks for food liquids

Ensure the sterility and quality of your liquid food products by utilizing advanced ...

Automatic banana peeling solution

Struggling with banana oxidation during puree production? This solution ensures swift, hi...

Continuous effect evaporators for tomato concentrate

Achieve high degrees of concentration for tomato paste and fruit jui...

Falling film concentrators for low viscosity fruit juices

Achieve high concentration levels in fruit and dairy products ...

Acai berry processing line

Enhance your acai berry production efficiency with an automated line that transforms traditional ...

Apple, pear, and kiwi juice extraction line

Achieve high-yield juice production from apples, pears, and kiwis while retain...

Aroma recovery system for natural juice extraction

Maximize aroma recovery in your juice production with a fully automate...

Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filli...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Aseptic filling solution for fruit juice and dairy products

Ensure product integrity and safety with this aseptic fillin...

Rotary cup filling and closing system

Maximize production efficiency with a system that offers precision filling and secure...

Glass jar filling system for processed cheese

Streamline your production line with a robust, high-speed filling solution d...

Forming, filling, and sealing solution for mini portions

Optimize your production line with a high-speed machine designed...

Forming, filling, and sealing system for liquid food products

Achieve precise portion control and versatile packaging wi...

Horizontal cartoning machine for medium to high-speed production

Optimize your cartoning process with precise loading an...

Continuous sugar dissolver for beverage and food production

Efficiently dissolve crystalline sugar in water up to 65°Bri...

Food pasteurizer for prepared foods

Optimize your prepared food production with precise temperature control and automated o...

Coiled heat exchanger for high viscosity products

Efficiently handle high-pressure, viscous product heating and cooling w...

Plate heat exchanger for food products

Achieve precise temperature control in your processing line with this plate heat exc...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Continuous sugar dissolver for beverage production

Optimize your production line with a system that efficiently dissolves...

Efficient pasteurizer for prepared foods

Achieve precise heat treatment and reduce product waste with a modular pasteurizat...

Food processor for high and low viscosity products

Achieve consistent recipe results and streamline your operations with ...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Autonomous ingredient dissolver for high volume dry ingredient mixing

Streamline your production by seamlessly mixing d...

Ingredient dissolver for small batches

Efficiently dissolve water-soluble powders and concentrates up to 200 cP with precis...

Coiled heat exchanger for viscous and particulate products

Optimize heat treatment of viscous and particulate foods with...

Industrial plate heat exchanger for food processing

Ensure consistent product quality with precise temperature control an...

Tubular heat exchanger for food products

Achieve precise temperature control and energy efficiency with this innovative tub...

Aseptic tank for blending and buffering

Optimize your production line with a secure aseptic tank that ensures precise in-li...

Blending tank for food preparations

Optimize your production line with a tank designed for efficient blending and storage o...

Liquid sugar storage tank

Ensure seamless liquid sugar management in your production line with advanced storage solutions de...

High-speed aseptic carton filling solution

Maximize production efficiency and meet growing demand with this high-output fi...

Filling system for gable top packages

Achieve precise, cost-effective filling with reduced energy consumption for chilled l...

Filling system for tetra brik 100 slim packages

Optimize your chilled product packaging with a high-speed filling system d...

High-speed carton filler for aseptic packaging

Maximize production efficiency with this high-speed filling solution that e...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Cardboard packer for secondary packaging

Streamline your packaging process with a high-speed, automated cardboard packer th...

Industrial tray shrink wrapper

Optimize your packaging line with rapid, resource-efficient shrink wrapping, accommodating di...

Bottle and jar rinsing system

Achieve optimal internal sanitization and cleanliness for bottles and jars with a versatile ri...

Self-adhesive label applicator for cylindrical and shaped bottles

Simplify label application on varied bottle shapes wi...

Manual monoblock for filling and capping jars

Optimize your jar filling and capping processes, even with high-temperature ...

Manual system for filling and capping jars

Ideal for efficiently handling liquid and semi-dense products, this manual syst...

Semi-automatic capping machines for versatile applications

Enhance your packaging efficiency with versatile semi-automat...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Automatic line for filling and capping spouted pouches

Streamline your production line with high-speed filling and cappin...

Industrial strawberry and blueberry washer

Ensure your soft fruits remain intact and impurity-free with this specialized w...

Mango juice production line

Streamline your mango juice production with a complete solution that efficiently transforms fres...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Jacketed kettle for porridge and sauce cooking

Efficiently heat and mix diverse liquid and slurry products with precise te...

Entry-level texture analysis system for Qc applications

Perfect for quality control labs, this portable system streamline...

Pilot plants for small-scale viscous product processing

Optimize your product development with pilot plants designed for ...

Scraped surface heat exchanger for high viscosity products

When dealing with complex formulations, achieve efficient hea...

Steady and moving pallet palletizers

Optimize your packaging line with advanced palletizing solutions designed to handle di...

Pallet depalletizers for industrial packaging

Efficiently handle layered packaging systems with versatile depalletizers de...

Efficient jam and marmalade production line

Optimize your fruit and bakery product lines with equipment designed for high-...

Automated mayonnaise and dressing production line

Ensure the consistent quality of your mayonnaise, dressings, and sauces...

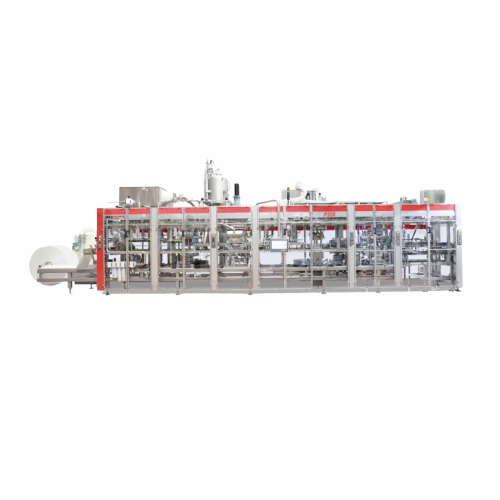

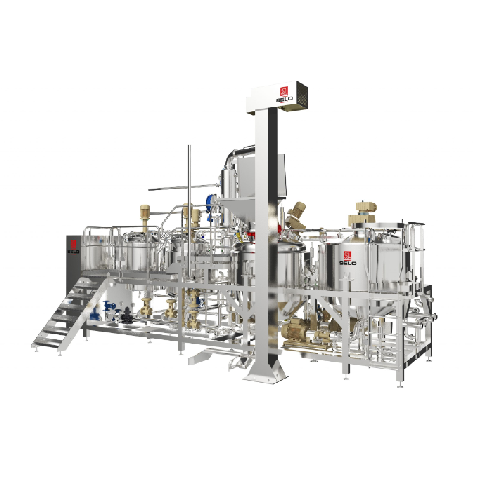

Jam production line

Optimize your jam production with our sophisticated line that ensures high capacity, consistent quality, ...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

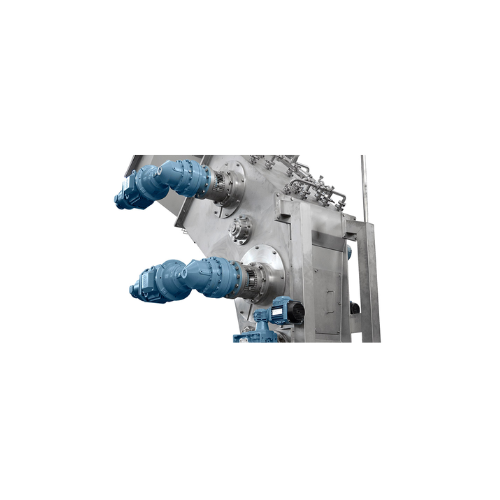

Industrial jam vacuum cooker

In a production setup of agri-food preserves, sauces, and other condiments, vacuum cooking at 5...

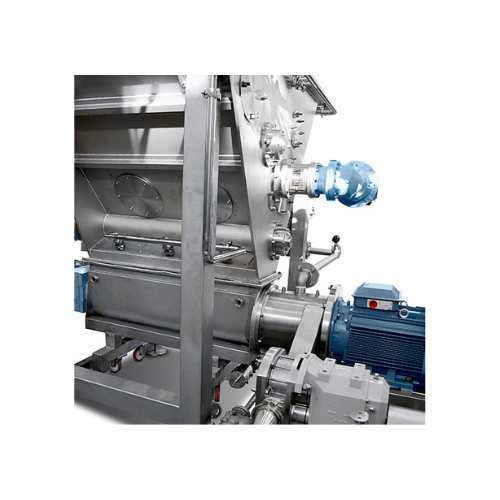

Small Scale Industrial Jam Cooker

Production of marmalades, jams, fruit concentrates, and sauces requires multiple steps. T...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Industrial vacuum cooker

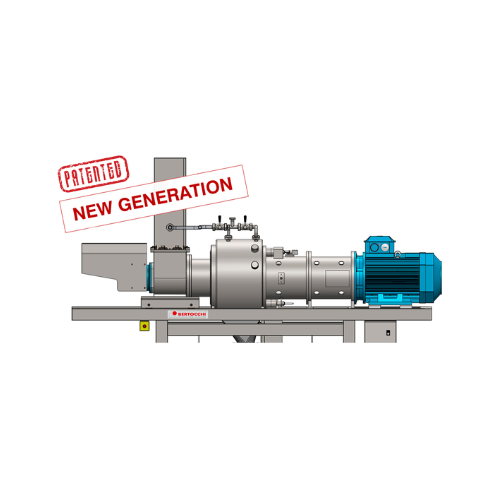

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Hygiene washer for food utensils

Thorough and quick cleaning of kitchen utensils, such as baskets, knives, trays, and other ...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Easy to use food processor for gastronomy sauces and pastes

For the development and production of high quality gastronom...

Food processor for making fruit jams for pastries

In a bakery environment fruit jams are often used for the decoration or...