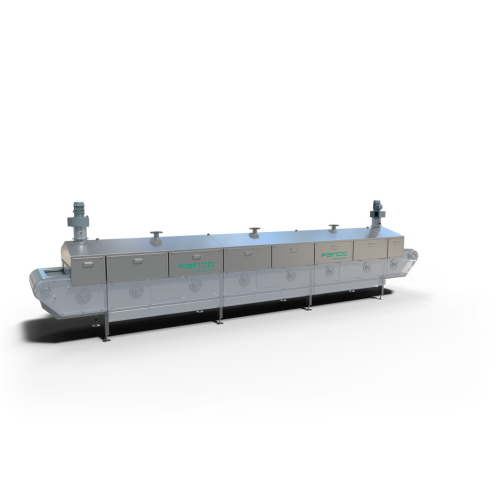

Industrial tunnel pasteurizer for rigid containers

Ensure consistent product quality and safety with a tunnel pasteurizer, designed for efficient heat treatment of rigid containers, while maintaining product integrity and extending shelf life.

Pasteurizes and Cools Rigid Container Contents

The Tunnel Pasteurizer from Fenco Food Machinery is engineered to efficiently pasteurize rigid containers such as glass jars, tin cans, and plastic bottles. This system utilizes a modular design with automatic control over the temperature and timing of the pasteurization and cooling processes, ensuring uniform heat treatment for various food and beverage products. With its fully drainable construction and stainless-steel materials, it offers superior durability and easy cleaning. The inclusion of advanced suction filters and a water-treatment system prevents contamination, promoting consistent operation. Capable of handling diverse applications from tomato paste and fruit jams to milk-based products, it achieves energy optimization that significantly reduces power consumption. Compliant with FDA standards, this machine supports continuous operation and integrates smoothly into existing production lines, with options for customization to your specific operational needs. With easy access panels, maintenance is streamlined, minimizing downtime and enhancing productivity.

Benefits

- Enhances product safety and quality with precise temperature control.

- Optimizes energy usage, reducing power consumption significantly.

- Minimizes maintenance time and costs through easy access and cleaning.

- Supports various product types and packaging materials for versatile application.

- Integrates seamlessly into production lines for efficient operation.

- Applications

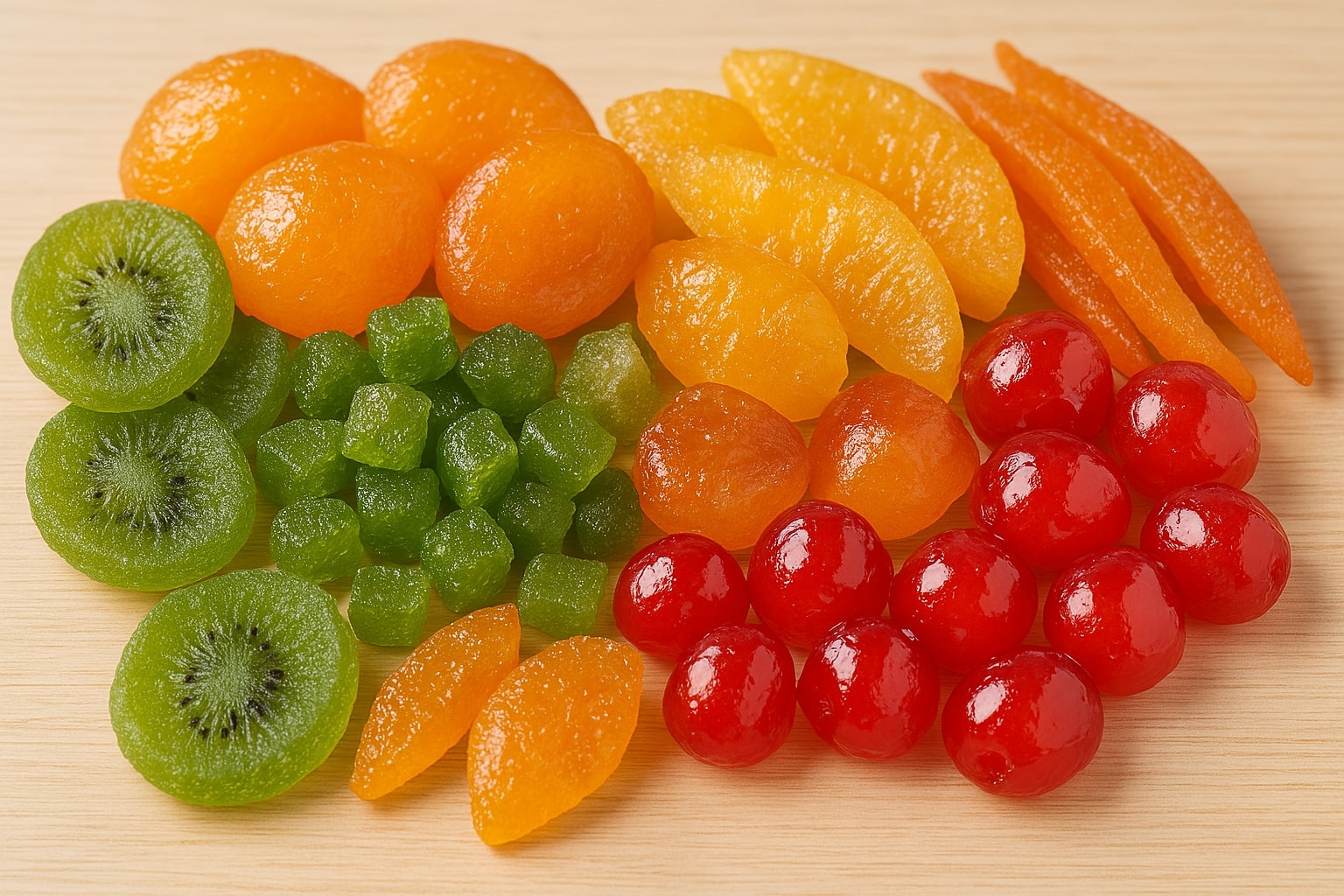

- Rigid containers, Formulated products, Milk products, Fruit products, Jams, Tomato products, Candied fruits

- End products

- Tinplate-bound fruit preserves, Rigid glass jars, Fruit compote, Bagged dried fruits, Plastic-wrapped milk cartons, Pureed tomato sauce, Peeled tomatoes in jars, Glass-packed candied fruits, Milk-based dessert cups, Pasteurized milk bottles, Packaged fruit jams, Bottled tomato juice, Tomato paste, Yogurt containers, Canned goods, Diced tomatoes in cans

- Steps before

- Filling, Heat Treatment Setup

- Steps after

- Cooling, Packing, Quality Inspection

- Input ingredients

- glass containers, tinplate tins, plastic containers

- Output ingredients

- pasteurized glass containers, pasteurized tinplate tins, pasteurized plastic containers

- Market info

- FENCO Food Machinery is known for engineering and manufacturing high-quality, customized food processing equipment. Renowned for innovation and reliability, they specialize in designing machinery tailored to specific production needs in the food industry.

- Material Compatibility

- Glass / Tinplate / Plastic

- Automation

- Automatic control

- Material

- Stainless steel

- Drainage

- Fully drainable

- Inspection Access

- Easy access with removable panels

- Energy Optimization

- Energy saving

- Capacity

- Modular structure

- Water-Treatment

- Integrated system to prevent algae and fungus

- Temperature Control

- Automatic

- Process Control

- Automatic control of time and temperature

- Coverage

- Nozzle distribution with 100% coverage

- Working mechanism

- Heat treatment tunnels

- Batch vs. continuous operation

- Continuous

- Automation level

- Automatic control of process, time, and temperature

- CIP/SIP

- Fully drainable machines

- Energy efficiency

- Optimized installed power

- Cleaning method

- Easy access with removable panels

- Corrosion resistance

- Stainless steel

- Compatibility with rigid containers

- Glass / Tinplate / Plastic

- Container type

- Glass / Tinplate / Plastic

- Machine footprint

- Modular structure

- Tank shape and size

- One or more tanks

- Material

- Completely stainless-steel structure

- Discharge method

- Fully drainable machines

- Access method

- Removable panels for easy inspection

- Control panel type

- Automatic control

- Material used

- Stainless steel