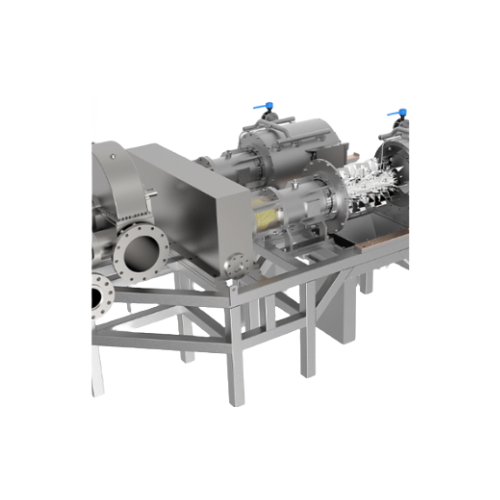

Tomato processing crushing mill

Optimize your production line with efficient chopping and refining, ensuring uniformity and purity in tomato paste, juices, and purees.

Enhances Processing of Fruits and Vegetables

The PTR30, Giubileo, and Crushing Mill from the CFT Group are engineered to revolutionize processing operations in the food industry. These systems excel in chopping, extracting, and refining, utilizing a robust multi-stage process to continuously handle a variety of applications, including tomato paste, fruit juices, and vegetable purees. Operational capacities reach up to 1,500 tons per day, accommodating both small-scale and large-scale production needs.

With a focus on versatility, these machines seamlessly integrate into existing lines, ensuring optimal size reduction and uniformity in heating and refining processes. The PTR30 features a powerful 30 kW motor and is strategically placed within cold-break and hot-break systems to maximize efficiency. The rubber-free destoning technology in Giubileo reduces contamination risk while maintaining product purity, complemented by customizable settings for precision processing.

Operators benefit from the systems’ energy efficiency and durable construction, featuring stainless steel options for enhanced corrosion resistance. Available with CIP systems, these machines simplify cleaning and maintenance, promoting longer equipment life cycles while ensuring compliance with industry standards. Configured for continuous, high-speed operations, they meet the rigorous demands of modern food processing with reliability and precision.

Benefits

- Maximizes production efficiency with continuous high-speed operation, reducing processing times.

- Ensures product purity with non-contaminating, rubber-free destoning technology.

- Customizable settings enhance process precision, allowing tailored production for specific needs.

- Robust construction minimizes maintenance requirements, ensuring long-term operational reliability.

- Energy-efficient design reduces operational costs and supports sustainable production practices.

- Applications

- Ketchup, Sauces, Jams, Tomato products, Vegetable purees, Fruit juices

- End products

- Strawberry jam, Apple juice, Carrot puree, Marinara sauce, Tomato paste, Classic ketchup

- Steps before

- Receiving, Washing, Sorting, Peeling

- Steps after

- Heating, Refining, Sterilization, Pasteurization, Aseptic filling, Packaging

- Input ingredients

- tomatoes, fruits, vegetables

- Output ingredients

- fruit pulp, vegetable pulp, juice, refined products, pomace

- Market info

- CFT Group specializes in manufacturing engineered-to-order equipment for the food and beverage industry, renowned for its innovative processing and packaging solutions, focusing on sustainability and advanced technology.

- Motor Power

- 30 kW

- Capacity

- 60 tons/hour

- Max Capacity

- Up to 1, 500 tons/day

- Min Capacity

- 48 tons/day

- Max Capacity

- Up to 3, 000 tons/day

- Automation level

- PLC or Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Minimal

- CIP/SIP

- Integrated CIP

- Cleaning method

- CIP / Manual

- Energy efficiency

- Optimized for low consumption

- Air incorporation control

- Present

- Processing Type

- Cold-Break and Hot-Break systems

- Material Type

- Tomatoes, Stoneless Fruits, Vegetables

- Motor Power

- 30 kW

- Capacity

- 60 tons per hour

- Compact Version Availability

- Yes

- Control panel type

- Standard / Custom

- Paddle pitch inclination adjustment

- Customizable

- Compact footprint

- Available