Fruit jam processing – What do you need for jam setting besides sugar, acid & pectin?

Strawberries, raspberries, blackberries, peaches, apricots, plums, or pineapples, you name it. All these fruits and many more, despite their differences, are suitable for jam processing.

Fruit jam processing can involve one single fruit or a combination of them. It all depends on the recipe. What’s important if you want to achieve a perfect jam set is that there must be a balance of the three key elements: sugar, pectin and acids.

Jam setting and preservation: the role of sugar in making fruit jam

Apart from being the sweetening agent par excellence, the sugar helps the fruit jam to set and has a preservative effect. Because sugar is hygroscopic, it binds water molecules to itself, reducing the water content in the jam. And low water content makes microbial growth more difficult. The final sugar content in jam should be 65-69%. If it is lower than 65%, the fruit jam is more easily subjected to spoilage affecting shelf life.

Acids for PH control and avoiding ionization

Sugar doesn’t do it all by itself. Acids are another essential component that allow pectin to form a gel network. A PH level between 2.8 and 3.3 is needed to avoid ionization of the COOH groups in the pectin to create the gel network. Fruits contain natural acids, but the content varies within the different fruits. You can add tartaric or citric acids to make up for any acid deficiency, such as lemon juice.

Pectin to form the fruit jam gel structure

Pectin consists of long chains of polysaccharide molecules, naturally found in fruits. When heating the jam mixture, the sugar molecules bind the water molecules in the fruit allowing the long pectin chains to bond each other, forming the gel network and the desired texture. When the fruit is fully ripe, it has lower pectin content compared to slightly under-ripe fruit. When processing low pectin fruit such as blueberries, blackberries or peaches, you need to add commercial pectin. This is usually extracted from leftover apple pomace or citrus peel under acid conditions, filtrated to separate residues, and further purified.

Tell us about your jam processing challenge

Are you looking for technology to set up or improve your fruit jam manufacturing process? And looking for the right production partner to build your line? Tell us about your fruit jam production process and we will connect you quickly with a partner that has experience in making your product.

Extracting fruit pulp from fresh fruits for your fruit jam process

The preparation or extraction process for fruit pulp in fruit jam making is very similar to preserving fresh fruit for other purposes. After harvest, fresh fruit requires washing, peeling, and pitting, depending on your process and type. If seeds remain in the fruit, they may alter the flavor of the pulp, giving it a more bitter taste. Before adding sugar, fruits like cherries or apricots (hard fruits) require simmering to soften the flesh, while most berries, for instance, don’t need this heating treatment.

Making jam with frozen fruit - how to prevent fruit from clumping?

When using frozen fruits as your starting ingredient, they need to be kept around −18 °C. Fruits can clump together when kept in the freezer for an extended period. This allows the formation of large ice crystals that can cause the fruits to stick together, creating a solid, frozen block.

Most fruit is frozen using the IQF method, Individual Quick Freezing, in which each piece of fruit is placed on a conveyor belt and frozen individually, avoiding clumping. Because it is a flash-freezing process, it is so rapid that no ice crystals can form. Frozen fruit is available with or without added sugar.

Fruit jam processing using the open kettle method

In the open vessel, jam is boiled in boiling water under atmospheric conditions using high batch temperatures. Heating the product for a prolonged time at high temperatures in an industrial cooker could affect the color and flavor of the jam, even leading to possible caramelization of the sugar. Although the vacuum process is becoming increasingly popular, the open kettle method is still used by producers who produce small capacities of jam, being that the initial installation of vacuum equipment is very expensive.

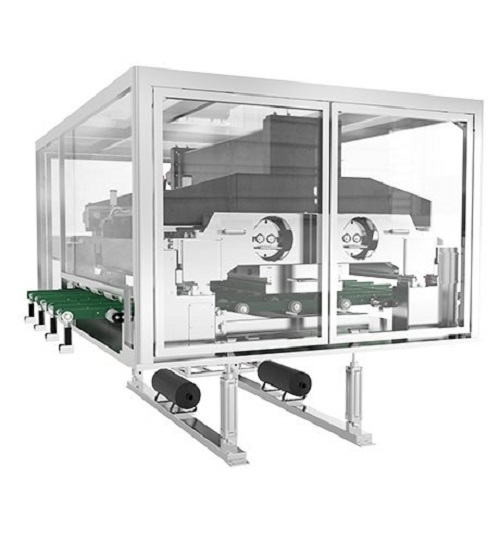

Vacuum cookers for lower temperature evaporation

The evaporation in the vacuum process takes place at a lower temperature which helps retain the fruits’ natural taste and organoleptic properties. The jam is placed under vacuum conditions to reduce the boiling water temperature in the vacuum process. The temperature range for evaporation is around 65-75 °C, which avoids the loss of the nutritional components and minimizes color and flavor change. In this case, the total time for concentration is about half as compared to that required with boiling at atmospheric pressure.

Using the vacuum cookers during the cooking stage means adding an extra pasteurization step before filling. The low temperatures of vacuum evaporation may not kill and eliminate all bacteria and microorganisms in the ingredients. Rapid pasteurization is performed at 85 to 95 °C, depending on the acidity of the jam.

Test the jam setting point using the sheet test

To check if the jellying point is reached, you can carry out different tests such as the boiling point method, refractometer method, or the well-known sheet test. The sheet test is done by taking out a portion of jam using a cool metal spoon during the boiling step. Drop the jam by turning the spoon to one side and watch as the jam runs off the spoon. The jam will form two drops. If the drops fall off the spoon together forming a sheet or a flake, the jellying point has been reached.

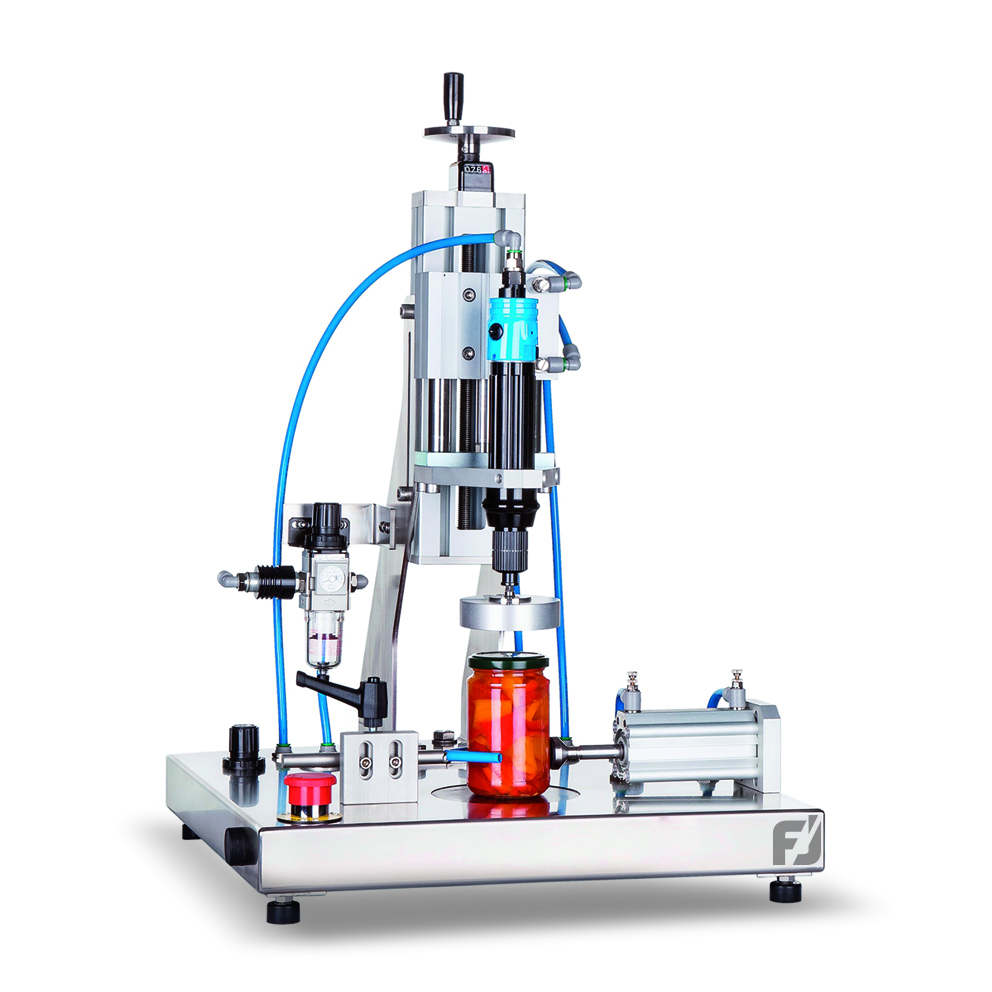

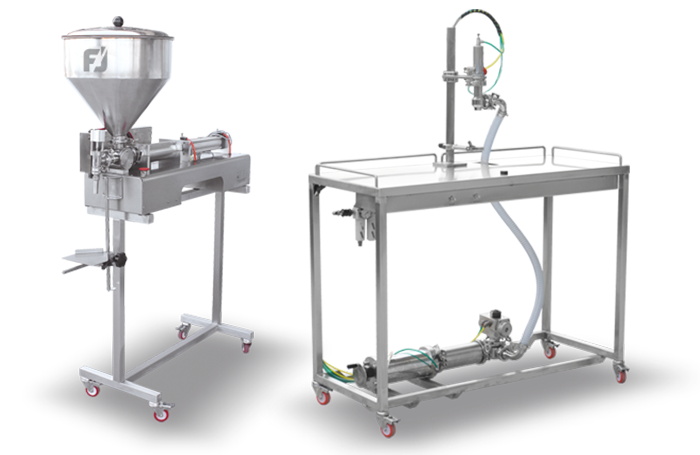

Filling and cooling jars in fruit jam processing

Some fruits, such as strawberries, have the tendency to float, making the filling challenging. This jam must be cooled during the strawberry jam making process until it is close to the setting point. The filling temperature for fruits that have a tendency to float should be around 57 °C. After filling, with such a low temperature, pasteurization (82 °C) of the container is necessary to ensure a safe product. For those fruits that do not have this problem, the filling temperature is around 79-85 °C.

In general, containers should be preheated before filling. This is done to prevent the boiling jam from being exposed to an excessive temperature difference with the cold container. Cooling jam depends on whether you have jam in glass jars or canned jam. The cans are simply run through a water bath, while air cooling through a tunnel is used for jam in glass jars.

Love & hate: the strawberry jam production process

We said that the perfect jam recipe balances the three ingredients: sugar, pectin and acids. Some fruits, such as apples, have a high pectin content, while others, such as strawberries, do not have enough pectin to allow gel formation. And besides that, strawberries also have a low acid content. Plus, they are made up of 90% of water.

Therefore, strawberries are boiled with sugar, which traps the water in order to improve the gel thickness. In the strawberry jam making process, producers must add commercial pectin and citric or tartaric acid to the mixture to compensate for the low acid and pectin content.

Make it better: using low methoxyl pectin to reduce sugar in fruit jam production

Making low-calorie jam depends on the type of pectin you use. Pectin can be classified into high methoxyl pectins (HMP) and low methoxyl pectins (LMP) based on their degree of esterification. High methoxyl pectin is used when making standard jam because it requires a lot of sugar (above 55%) to gel. Low methoxyl pectins can form a jam structure without bonding with sugars and acids, but it requires calcium to activate the gelling process. The calcium bonds that hold the liquid together can create the gel.

Make it better: low-calorie jam using stevia as a replacement for sugar

Nowadays, people are increasingly focused on leading a healthy lifestyle and eating foods high in nutrients and low in fats. Jam is a good compromise, being made of fruits that are an optimal source of minerals, vitamins, and fibers. On the other side, it is well known that high sugar content is needed for the jam to form its gel structure.

Sugar though can be replaced with a natural and non caloric sweetener, stevia. Stevia was proved to have many beneficial effects on people’s health, and believe it or not, its main component, stevioside, is 300 times sweeter than sucrose. Jam made with stevia results in a low-calorie product with a taste and flavor close to traditional jam.