Basket tracking system for automated batch retort systems

Efficiently manage and monitor your batch processing with a system that tracks, records, and ensures quality control to streamline operations and flag discrepancies in real-time.

Tracks, Records, and Monitors Batch Processes

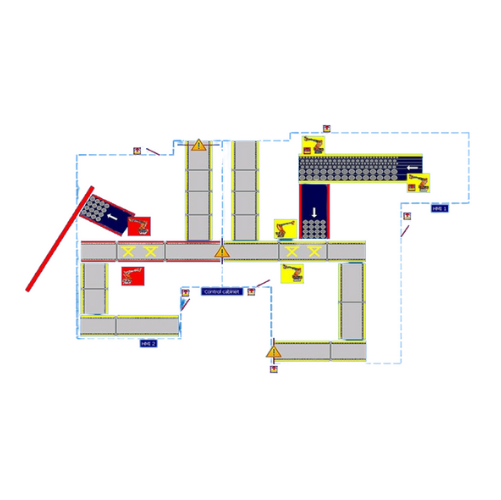

The Basket Tracking System from JBT is a sophisticated solution designed for precision monitoring and data recording in batch processing environments. It coordinates all movements of baskets, ensuring that each phase—from loading to unloading—is meticulously tracked using barcode technology. This system is especially critical for food processors and beverage manufacturers dealing with diverse products such as infant formula, juices, sauces, and ready meals. It excels in environments where maintaining high standards of quality control is paramount, like poultry, meat, and seafood processing. The system flags any anomalies, necessitating quality control intervention to ensure compliance and safety.

This equipment integrates seamlessly into automated batch retort systems, offering complete oversight with its ability to monitor preprocess dwell time deviations. Its PLC-controlled framework supports easy integration with existing lines, providing a comprehensive overview for operators. Made with durable materials suitable for various industries, it promises reliability and longevity even under demanding conditions. The Basket Tracking System allows you to focus on throughput and quality, protecting your processes against errors with prompt flagging and accurate data capture. Plus, it facilitates compliance with industry standards, ensuring your production line remains efficient and compliant.

Benefits

- Ensures product integrity with accurate anomaly detection and flagging.

- Enhances operational efficiency through comprehensive batch coordination and monitoring.

- Reduces human error with automated tracking of preprocess dwell times.

- Supports strict quality control with precise data recording and process oversight.

- Adapts to diverse product types, streamlining operations for both solid and liquid production lines.

- Applications

- Beverages, Soups, Sauces, Seafood, Ready meals, Pet food, Meat, Fruits, Oils, Nuts, Dressings, Poultry, Seasonings, Baby food, Juices

- End products

- Ketchup, Olive oil, Ranch dressing, Salmon fillets, Tomato soup, Black pepper seasoning, Infant formula, Chicken breast, Orange juice, Dry dog food, Ground beef, Microwaveable lasagna, Almond butter, Applesauce, Soft drinks

- Steps before

- Loading, In-container sterilization, Process start

- Steps after

- Unload, Quality control, Packing

- Input ingredients

- baskets, raw food products

- Output ingredients

- processed baskets, sterilized food products, flagged baskets (for QC review)

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Automation

- Fully Automated

- Data Recording

- Continuous Data Logging

- Movement Coordination

- Real-Time Coordination

- Barcode Tracking

- Integrated Barcode Scanners

- Anomaly Detection

- Automatic Anomaly Flagging

- System Overview

- Complete System Monitoring

- Dwell Time Monitoring

- Pre-process Dwell Time Tracking

- Barcode integration

- Yes

- Anomaly detection

- Automated flagging

- Dwell time monitoring

- Continuous

- Automation level

- PLC-controlled

- Data recording

- Automated

- Process oversight

- Full system overview

- Integration with existing systems

- Compatible

- Manual override capability

- QC privilege required

- Batch vs. continuous operation

- Batch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Basket

- Product type

- Food, Beverage

- Control panel type

- Touchscreen HMI

- Integration possibilities

- SCADA/PLC systems

- Barcode scanner type

- Optical laser

- Data recording customization

- Configurable parameters