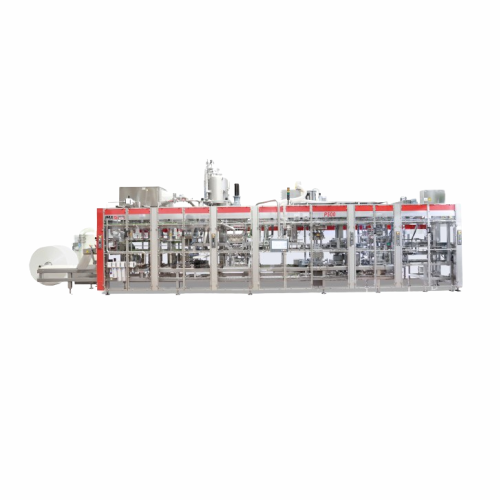

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing material waste while ensuring consistent portion control in dairy, spreads, and sauces.

Forms, Fills, and Seals Portion Cups

The P500 from IMA Group is a high-performance form, fill, and seal machine engineered for continuous processing of portion cups across diverse food and dairy applications. Its multi-stage thermoforming and sealing process ensures precise product size and shape, optimizing material use and minimizing waste. Ideal for liquid and semi-liquid products such as soft cheeses, sauces, and jams, the P500 efficiently handles a throughput of up to 129,600 portion cups per hour. Featuring clean, ultra-clean, and aseptic operation standards, this machine integrates seamlessly into packaging lines, offering options for different hygiene classes and servo-driven automation for precision control. With the capability to handle packaging materials like PS, PET, and PP, the P500 is available with configuration options like low-waste punch units and CIP systems to ensure easy maintenance and minimal downtime.

Benefits

- Maximizes production efficiency with throughput up to 129,600 cups per hour.

- Ensures hygiene compliance with options for clean, ultra-clean, and aseptic standards.

- Minimizes material waste through advanced low-waste punching technology.

- Enhances operational flexibility, accommodating various cup designs and materials.

- Simplifies maintenance with integrated CIP systems for quick, contamination-free cleaning.

- Applications

- Ketchup, Spreads, Sauces, Jams, Soft cheese, Cream cheese, Desserts, Dressings, Butter, Mayonnaise, Honey, Mustard, Dairy products

- End products

- Blue cheese dressing cups, Hollandaise sauce portions, Dijon mustard sachets, Reduced-fat mayonnaise pouches, Fresh mozzarella cups, Herb butter portions, Chocolate dessert cups, Whipped cream cheese containers, Single-serve ketchup packets, Raspberry preserves packs, Organic honey pods, Strawberry jam mini-packs

- Steps before

- Ingredient preparation, Mixing, Heating, Emulsification

- Steps after

- Case packaging, Sterilization, Cool storage, Logistics and distribution

- Input ingredients

- PS, PET, PP, PLA, PS multilayer, PVC, Paper-based lid materials, PET-based lid materials, Alu-based lid materials, heat sealable materials, bottom web

- Output ingredients

- butter, desserts, cream cheese, soft cheese, ketchup, mustard, mayonnaise, sauces, jams, honey, spreads, dressings, portion cups

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Nominal Output

- Up to 129, 600 cups/h

- Hygienic Standards

- Clean, Ultra-clean, Aseptic

- Material Compatibility

- PS, PET, PP

- Material Width

- Max. 550 mm

- Draw-off Length

- Max. 320 mm

- Forming Depth

- Max. 40 mm

- Reel Diameter (Bottom Web)

- Max. 1, 200 mm

- Reel Diameter (Lid Material)

- Max. 400 mm

- Control System

- Schneider Electric

- Punching Principle

- Low-waste, multi punch

- Filling Speed

- Phase-specific

- Output Range

- 54, 000 – 129, 600 cups/h

- Working Mechanism

- Form, Fill and Seal

- Integrated Steps

- Thermoforming, Filling, Sealing, Packaging

- Batch vs Continuous Operation

- Continuous

- Automation Level

- PLC / Servo Motors Controlled

- Cleaning Method

- Clean-in-Place (CIP)

- Material Handling Capability

- PS, PET, PP

- Nominal Output

- Up to 129, 600 cups/h

- Hygienic Standards

- Clean, Ultra-clean, Aseptic

- Compatible Materials

- PS, PET, PP

- Lid Material Compatibility

- Paper, PET, Alu-based, heat sealable materials

- Heat Sealable Lid Materials

- Yes

- Machine Footprint

- Not specified

- Material width

- max. 550 mm

- Draw-off length

- max. 320 mm

- Forming depth

- max. 40 mm

- Reel diameter (Bottom web)

- max. 1, 200 mm

- Reel diameter (Lid material)

- max. 400 mm

- Output

- 54, 000 – 129, 600 cups/h

- Cup Shapes

- Various

- Material compatibility

- PS, PET, PP

- Hygienic standards

- Clean, ultra-clean, aseptic (steam aseptic)

- Punching principle

- Low waste, multi punch

- Bottom web processing

- PP processing

- Lid material

- Lateral reel feed with reel diameter max. 600 mm