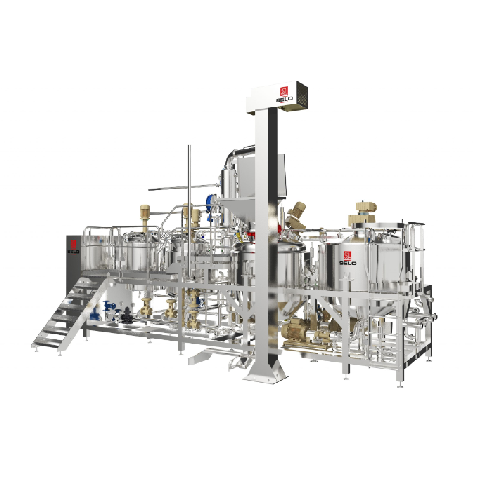

Jam production line

Optimize your jam production with our sophisticated line that ensures high capacity, consistent quality, and effortless recipe transitions while preserving authentic fruit flavors and textures. Perfect for maintaining competitiveness and meeting evolving consumer trends in preserved foods.

Processes and Packages Jams and Preserves

The jam and preserve production line is offered by Selo, a notable manufacturer known for their hygienic and high-capacity food processing solutions. This fully automated line is engineered to optimize the production of jams, jellies, marmalades, and fruit preserves, integrating seamlessly into your existing operations.

Specializing in continuous processing, it features a multi-stage cooking and pasteurization system that ensures consistent product quality and flavor retention, all while managing high throughput demands. Capable of processing a broad range of products, from strawberry jam to blueberry bakery filling, it supports both cool and hot filling per your production needs.

Equipped with PLC-controlled automation, the line permits real-time monitoring and efficient control, facilitating quick recipe changes and reducing waste. To uphold strict hygiene standards, it incorporates a Clean-In-Place (CIP) system for effective sterilization between batches, ensuring products meet regulatory compliance such as EHEDG.

Material options include robust stainless steel constructions for enhanced durability and corrosion resistance. Selo also offers engineering support for customizable features, allowing configurations tailored to your operational requirements and scale. Whether you’re a large-scale jam producer or a boutique confectionery, this production line provides the flexibility and reliability needed to meet market demands.

Benefits

- Maximizes production efficiency with high-capacity, continuous operation.

- Maintains product quality and integrity with minimized fruit damage.

- Reduces waste and adapts to market demands with quick recipe changes.

- Ensures hygiene and compliance with CIP-equipped, easy-to-clean design.

- Allows year-round production flexibility by utilizing up to 80% frozen fruit.

- Applications

- Jellies, Jams, Fruit preserves, Marmalades, Bakery fillings

- End products

- Blueberry bakery filling, Apple jelly, Orange marmalade, Strawberry jam, Peach preserve, Apricot preserve, Fruit tart filling, Blackcurrant jam, Mixed fruit marmalade, Raspberry jelly

- Steps before

- Pre Engineering, Ingredient Preparation, Fruit Sorting, Fruit Washing, Fruit Cutting

- Steps after

- Cooling, Packing, Labeling, Quality Control, Distribution

- Input ingredients

- fresh fruits, frozen fruits, sugar, preservatives, flavorings

- Output ingredients

- jams, jellies, marmalades

- Market info

- Selo is known for providing industrial engineered-to-order equipment solutions, specializing in processing and packaging systems. They are reputed for their innovative engineering, customization capabilities, and a strong commitment to quality and customer satisfaction within various industries.

- Capacity

- High capacity

- Fruit percentage capability

- Up to 80% frozen fruit

- Process time

- Short process time

- Filling options

- Cool and hot filling

- Recipe changeover

- Quick with minimal waste

- Automation

- Automatic process lines

- Hygienic design

- EHEDG standard

- Working mechanism

- Fully automatic

- Automation level

- High (PLC-controlled)

- Batch vs. continuous operation

- Batch or Inline Continuous

- Changeover time

- Quick recipe changes

- CIP/SIP

- CIP

- Cleaning method

- User-friendly, hygienic design

- Energy efficiency

- Efficient production process

- Control panel type

- Touchscreen HMI

- Integration possibilities

- SCADA, MES systems

- Recipe management

- Automated, quick changeover

- Filling options

- Cool and hot filling

- Fruit content settings

- Whole fruit, pureed

- Pre-testing

- Technology Center trial batches

- Hygienic design standard

- EHEDG compliant

- Aroma recovery

- Available

- Automatic brix control

- Available