Agitators for mixing tanks

Optimize mixing operations with versatile agitators designed for various viscosities and fluid types, ensuring uniformity in blending, suspension, and dispersion across your production line.

Mixes, Suspends, and Homogenizes Various Products

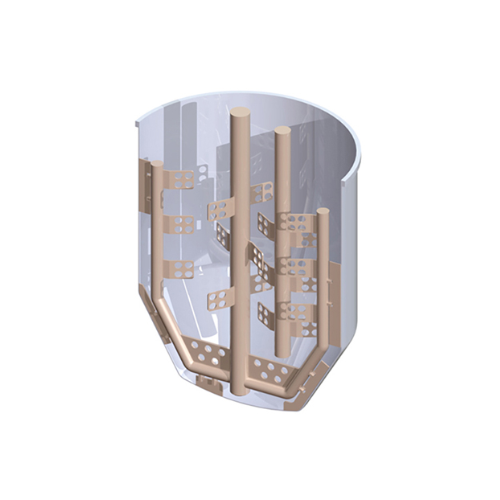

The Agitators for Standard Tanks from INOXPA are engineered to meet diverse mixing needs across the food, beverage, cosmetic, and pharmaceutical industries. These agitators employ a combination of anchor, propeller, blade, and turbine designs, ensuring effective mixing for products ranging from jam to protein shakes. Capable of batch and continuous operations, they support high-speed processing with the flexibility of manual adjustments. The agitators are designed to fit tanks with rounded or conical bottoms, promoting efficient suspension, emulsification, and homogenization processes.

Applications include the production of yogurts, fruit juices, and liquid soaps, with options for handling varying viscosities. With precise mixing mechanics, these agitators prevent solid deposition and ensure consistent product quality. Constructed from durable stainless steel, they offer excellent corrosion resistance and compatibility with CIP systems for easy maintenance. The equipment is PLC-controlled for seamless integration with existing production lines, offering customizable configurations to suit specific operational demands. Compliant with GMP and FDA standards, these agitators assure adherence to stringent industry regulations.

Benefits

- Enhances product consistency with precise mixing action across various viscosities.

- Increases operational efficiency by integrating into both batch and continuous production lines.

- Reduces contamination risk through easy-to-clean CIP compatibility.

- Minimizes downtime with robust, corrosion-resistant stainless steel construction.

- Ensures compliance with industry standards, including GMP and FDA.

- Applications

- Cosmetic industry, Food industry, Dairy industry, Bakery industry, Pharmaceutical industry, Beverage industry

- End products

- Protein shake, Jam, Cough syrup, Mayonnaise, Face cream, Cake batter, Yogurt, Liquid soap, Fruit juice, Ice cream mix

- Steps before

- Filling, Pre-Heating, Material Preparation

- Steps after

- Heat Treatment, Filtration, Packing

- Input ingredients

- highly viscous products, non-Newtonian fluids, low-viscosity products, solid-in-liquid solutions, suspensions, liquids, emulsification substances, dispersion substances

- Output ingredients

- mixed highly viscous products, homogenized non-Newtonian fluids, suspended solids in liquid, dispersed and homogenized mixtures, emulsified products

- Market info

- INOXPA is known for its expertise in manufacturing stainless steel components and equipment, particularly for the food, dairy, cosmetic, and pharmaceutical industries. They are reputed for high-quality, hygienic, and reliable processing solutions.

- Agitator Type

- Anchor-type, Propeller-type, Blade-type, Turbine-type

- Mixing Capacity

- Highly viscous to low-viscosity products

- Mounting Type

- Rounded or conical bottom tanks

- Operation Speed

- Medium to high speeds

- Axial Flow

- Yes

- Peripheral Velocity

- 2 to 7 m/s

- Flow Deflector

- Optional, depending on application

- Viscosity Range

- Non-Newtonian to low-viscosity

- Emulsification and Dispersion Process

- Yes, for turbine agitators

- Installation Requirement

- Radial flow deflector for center-mounted agitators

- Mixing type

- Anchor / Propeller / Blade / Turbine

- Speed control

- Manual / Automated

- Viscosity range

- Low to High

- Tank bottom type compatibility

- Rounded / Conical

- Application type

- Suspension / Dispersion / Homogenization

- Flow type

- Axial / Radial

- Installation position

- Centered / Off-centered

- Abrasion resistance

- High

- Biological compatibility

- Food-grade

- Cleanability

- CIP compatible

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- Varied

- Fluid type

- Newtonian / Non-Newtonian

- Product viscosity

- Highly viscous / Low-viscosity

- Agitator type

- Anchor, Propeller, Blade, Turbine

- Tank shape

- Rounded or Conical Bottoms

- Mounting orientation

- Vertical / Side-entry

- Anchor shape

- U-shaped, Helical

- Propeller type

- Marine, Gamma, Lineflux

- Blade type

- T6 Inclined, T11 Inclined, High Flow

- Tank compatibility

- Standard Tanks

- Peripheral speed

- 2 to 7 m/s

- Control panel type

- PLC / HMI

- Agitator type

- Anchor / Propeller / Blade / Turbine

- Mounting style

- Top-entry / Side-entry

- Bottom shape compatibility

- Rounded / Conical

- Flow deflector options

- Radial / Axial