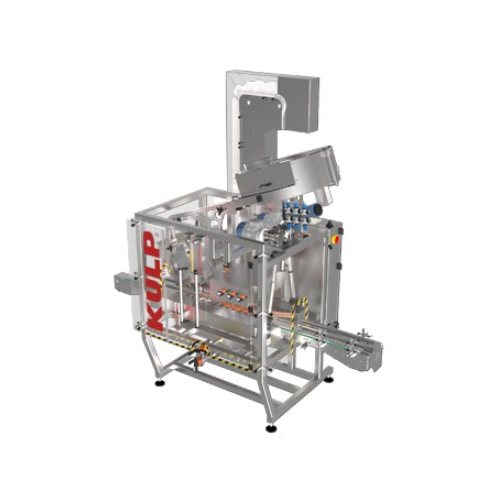

Continuous inline capping system

Perfect for high-speed operations, this system ensures precise capping of diverse container shapes and cap types, enhancing production efficiency by allowing seamless adjustments without halting the production line.

Caps, Sorts, and Tightens Various Container Types

The KAP 938 Capping Machine from Kulp Makina stands out with its continuous inline capping system, efficiently managing various cap types and container shapes without pausing the production line. Designed for high-speed operations, it excels in packaging applications across food, beverage, cosmetics, and chemical industries. This machine processes up to 6,000 packages per hour and features a state-of-the-art cap sorting system with quick-change capabilities for seamless transitions between cap sizes. The step motor-driven capping head with adjustable torque ensures precise application, minimizing cap damage while accommodating round, oval, square, and rectangular containers. With a user-friendly touch screen interface and adjustable conveyor system, it integrates effortlessly into existing production lines. Constructed from heavy-duty stainless steel and anodized aluminum, it offers durability and resistance to industrial environments, making it a reliable choice for high-demand packaging lines.

Benefits

- Boosts production efficiency with a seamless continuous capping process, minimizing downtimes.

- Supports versatile packaging needs with quick cap size adjustments, enhancing line flexibility.

- Enhances product integrity by preventing cap damage through precise torque control.

- Simplifies operations with an intuitive user interface, reducing training time.

- Sustains high operational durability in demanding environments with robust stainless steel construction.

- Applications

- Chemical packaging, Beverages, Personal care products, Household products, Cosmetic products, Food products, Pharmaceuticals

- End products

- Canned soups, Chemical solvent bottles, Glass bottled juices, Cleaning spray bottles, Pill containers, Face cream jars, Shampoo bottles

- Steps before

- Filling, Sealing

- Steps after

- Labeling, Packaging

- Input ingredients

- containers, metal twist-off caps, plastic screw caps, metal screw caps, trigger caps, dispenser caps, spray caps

- Output ingredients

- capped containers

- Market info

- Capacity

- 6000 Packages/Hour

- Speed

- 100 Caps/Minute

- Automation

- Automatic Capping System

- Capping System

- Continuous Inline Capping

- Voltage

- 380 volts / 50-60 Hz

- Cap Types

- Metal Twist-Off, Plastic Screw, Metal Screw, Trigger, Dispenser, Spray

- Container Compatibility

- Round, Oval, Square, Rectangular

- Capping Torque

- Adjustable

- Construction Material

- Stainless Steel, Anodized Aluminium

- Interface

- Touch Screen Interface

- Conveyor Line

- 3 Meter Speed Adjustable

- Stability

- Superior stability with belt system

- Working mechanism

- Continuous Inline Capping System

- Automation level

- Automatic

- Changeover time

- Quick change

- Container stability

- Belt system for high and soft containers

- Cleaning method

- Manual

- Abrasion resistance

- Stainless steel components

- Corrosive resistance (e.g. acids)

- Stainless steel and anodized aluminium

- Cleanability

- Easy to clean with stainless steel surfaces

- Density/particle size

- Suitable for a variety of cap densities

- Machine footprint dimensions

- Compact

- Container compatibility

- Round, oval, square, rectangular

- Cap type compatibility

- Metal Twist-Off, Plastic Screw, Metal Screw, Trigger, Dispenser, Spray

- Frame material

- Stainless steel and anodized aluminium

- Control panel type

- User friendly touch screen interface

- Feed/discharge method

- Integrated cap elevator and sorter

- Cap chute

- Adjustable for different caps

- Capping head

- Step motor driven with adjustable torque

- Control panel type

- User friendly touch screen interface

- Integration possibilities

- PLC-controlled with OMRON PLC, Touch Screen, Drivers

- Cap sorting,distribution

- Mechanical sorter with quick-change cap systems

- Capping head adjustment

- Step motor with adjustable capping torque

- Container handling

- Belt system supporting various sizes and types

- Electrical power requirement

- 380 volts / 50-60 Hz

- Construction materials

- Heavy duty stainless steel frame