Crunching and dosing solution for frozen fruits and vegetables

Streamline your processing line with a versatile system designed to efficiently crunch and dose frozen fruits and vegetables, enhancing production flow and ensuring precision in feeding downstream processes.

Crunches and Doses Frozen Fruits and Vegetables

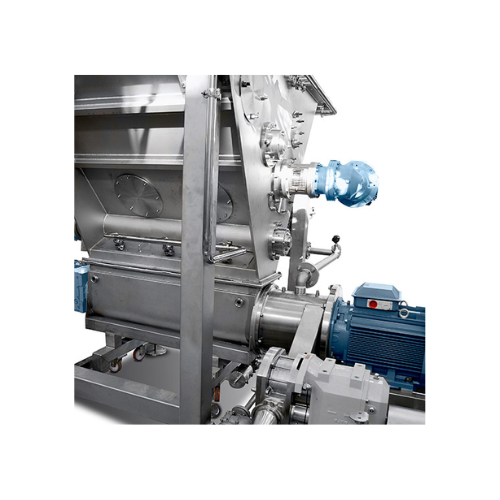

The CRUNX Series by Bertocchi Srl offers a robust solution for efficiently processing frozen fruits and vegetables. This machine specializes in crunching and dosing frozen produce, seamlessly preparing it for further downstream processes such as extraction, refining, and blending. The system is designed to handle various product forms, including puree slabs, blocks, and drums, with specific models like Delta CRUNX and Gamma CRUNX providing flexibility for different throughput needs—from 2 to 10 tons per hour.

Integration into existing production lines is straightforward, with automation managed via a PLC system, ensuring high-speed continuous operation. Its energy-efficient design optimizes motor control, reducing energy consumption significantly. The CRUNX Series is constructed from durable materials, supporting operations in food, beverage, and aseptic processing industries, while maintaining ease of cleaning and maintenance with its user-friendly design. This makes it an ideal choice for companies focusing on high-quality puree production, baby foods, jams, and juices.

Benefits

- Enhances production efficiency with continuous, high-speed operation.

- Integration-ready design minimizes setup time in existing lines.

- Reduces energy costs through optimized motor control.

- Supports diverse applications with versatile processing capabilities.

- Streamlined cleaning and maintenance reduce operational downtime.

- Applications

- Jam, Fruit purees, High-quality puree, Frozen fruits, Frozen vegetables, Baby food, Fruit juices

- End products

- Grinded frozen spinach, Strawberry jam, Apple puree slabs, Premium pear puree, Organic baby apple puree, Grinded frozen strawberries, Mango fruit juice

- Steps before

- frozen fruit preparation, frozen vegetable preparation

- Steps after

- extraction, refining, blending, thermal treatment, high temperature storage, aseptic processing

- Input ingredients

- frozen fruit puree slab, frozen puree block, frozen puree drum, rolling IQF

- Output ingredients

- grinded frozen fruit, grinded frozen vegetables, extraction, refining, blending, thermal treatment of puree, high temperature storage, aseptic, baby foods, jam, fruit juices, high quality puree

- Market info

- Bertocchi is known for manufacturing engineered-to-order industrial equipment, specializing in custom process solutions for the food and beverage industry. They have a strong reputation for innovation, quality, and reliability in producing machinery tailored to customer specifications.

- Capacity

- 2 to 10 t/h

- Process Type

- Crunching and Dosing

- Product Compatibility

- Frozen puree slab, block, drum, rolling IQF

- Model Sizes

- Delta

- Delta Model Capacity

- 2 to 8 t/h

- Gamma Model Capacity

- 6 to 10 t/h

- Working mechanism

- Crunching and Dosing

- Process type

- Batch

- Max capacity

- 2 to 10 t/h

- Final product size

- Grinded frozen fruits and vegetables

- Product compatibility

- Frozen puree slabs, blocks, drums, rolling IQF (SA model)

- Delta model variability

- 5 Different Model Sizes

- Gamma model variability

- 2 Different Model Sizes

- End use flexibility

- Extraction, refining, blending, thermal treatment

- Density/particle size

- 0.5–2.5 g/cm³

- Discharge Method

- Feeding downstream plants

- Drum Size

- Various sizes

- Max Capacity

- 2 to 10 t/h

- Container Type

- Frozen puree slab, block, drum, rolling IQF

- Control panel type

- Available

- Discharge method

- Grinded product ready for feeding

- Compact footprint

- Modular design

- Model sizes

- 5 models for Delta, 2 models for Gamma