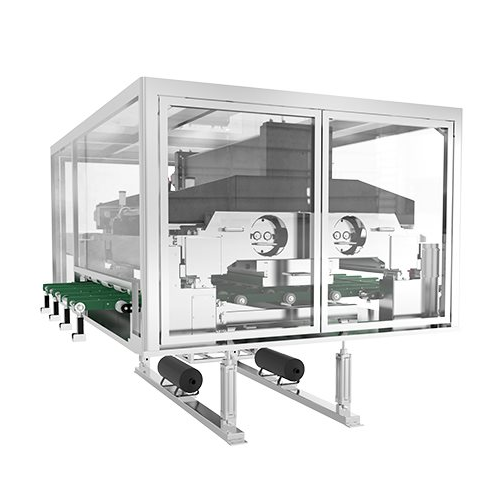

High-viscosity mass depositor

Efficiently deposit high-viscosity masses like caramel and jam with precision, while the integrated mould shaking ensures flawless, air-free end products.

Deposits High Viscosity Masses and Chocolate Chips

The ETX Depositor from Aasted stands out with its ability to handle high viscosity masses such as caramel, jam, and toffee with precision and speed. This versatile depositor doubles as both a center filling and chocolate chip depositor, making it a flexible solution for complex manufacturing lines. Integrated with a mold shaker, the ETX eliminates trapped air, ensuring superior product quality. It’s ideal for producing caramel squares, jam-filled cookies, and chocolate-covered bars.

Capable of continuous high-speed operations, the ETX offers seamless integration within your production line, from melting tanks to enrobers. Built with easy cleaning and maintenance in mind, the depositor supports hygienic stainless-steel construction. With its high throughput efficiency, adaptable to your specific requirements, the ETX suits the needs of chocolate manufacturers, confectionery producers, and bakeries aiming for precise and high-quality production runs.

Benefits

- Enhances product quality by eliminating trapped air with integrated mold shaking.

- Increases production efficiency with high-speed, continuous operation.

- Offers customization flexibility to meet diverse production needs.

- Simplifies maintenance with easy-to-clean stainless-steel construction.

- Seamlessly integrates into existing lines, optimizing workflow.

- Applications

- Jam, Bakery, Confectionery, Toffee, Filled bars, Chocolate chips, Chocolate, Caramel

- End products

- Filled chocolate pralines, Chocolate chip cookies, Jam-filled cookies, Caramel squares, Toffee chews, Chocolate-covered bars, Fruit-filled pastries

- Steps before

- Feeding, Mixing, Melting, Tempering

- Steps after

- Mould Shaking, Cooling, Enrobing, Filling, Weighing

- Input ingredients

- high viscosity masses, caramel, jam, toffee, chocolate mass

- Output ingredients

- filled bars, deposited chocolate, center filled products, chocolate chips

- Market info

- Aasted is known for its expertise in manufacturing equipment for the chocolate, bakery, and confectionery industries, offering solutions like tempering, molding, and baking machinery with a strong reputation for innovation and quality.

- Capacity

- Up to 2½ tons/hr

- Melting tank capacity range

- 150 kg to 3, 000 kg

- Material handled

- High viscosity materials such as caramel, jam, and toffee

- Material compatibility

- Chocolate chip, high viscosity masses

- Precision

- High speed and accuracy

- Cleaning Method

- Easy cleaning

- Mold shaking

- Integrated

- Lifting table

- Built-in

- High viscosity mass handling

- Yes

- Center filling deposition

- Yes

- Integrated mold shaking

- Yes

- Automation level

- High speed and accuracy

- Cleaning method

- Easy cleaning

- Flexibility and customization

- Adjustable to specific requirements

- Versatility in product types

- Filled bars, chocolate chips

- Easy maintenance

- Yes

- High viscosity compatibility

- Caramel, jam, toffee, chocolate

- Cleanability

- Easy cleaning

- Corrosive resistance (e.g. acids)

- Stainless steel

- Filling purpose

- Center filling, Chips depositing

- Machine footprint

- Compact/bespoke to client requirements

- Tank capacity

- 150–3000 kg

- Discharge method

- Integrated mold shaking

- Control panel type

- PLC-Controlled

- Lifting table inclusion

- Built-in

- Mould shaking integration

- Integrated

- Maneuverability

- Easily maneuverable

- Specific requirements adjustment

- Adapts to specific needs

- Add-on equipment options

- Feeder Mixer, Filling, Weighing St., Melting Tank, Pumps