Pulper finisher for tomato and cold extraction

Enhance your production line efficiency with a pulper finisher designed to deliver high-quality purees and refined juices by effectively separating impurities from fruits and tomatoes, ensuring precision and consistency in every batch.

Separates and Refines Purees and Juices

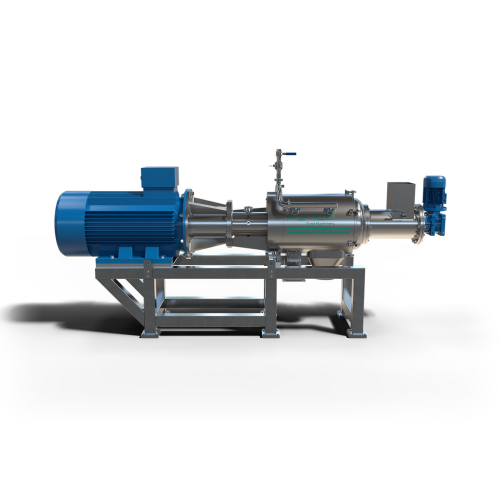

The Pulper Finisher Machine from FENCO Food Machinery is engineered to optimize your tomato and fruit processing operations. This robust machine addresses the challenge of impurity removal by effectively separating and refining purees and juices. Its heavy-duty design supports continuous, high-speed processing, handling up to 60 tons per hour for tomatoes and 15 tons per hour for cold extraction.

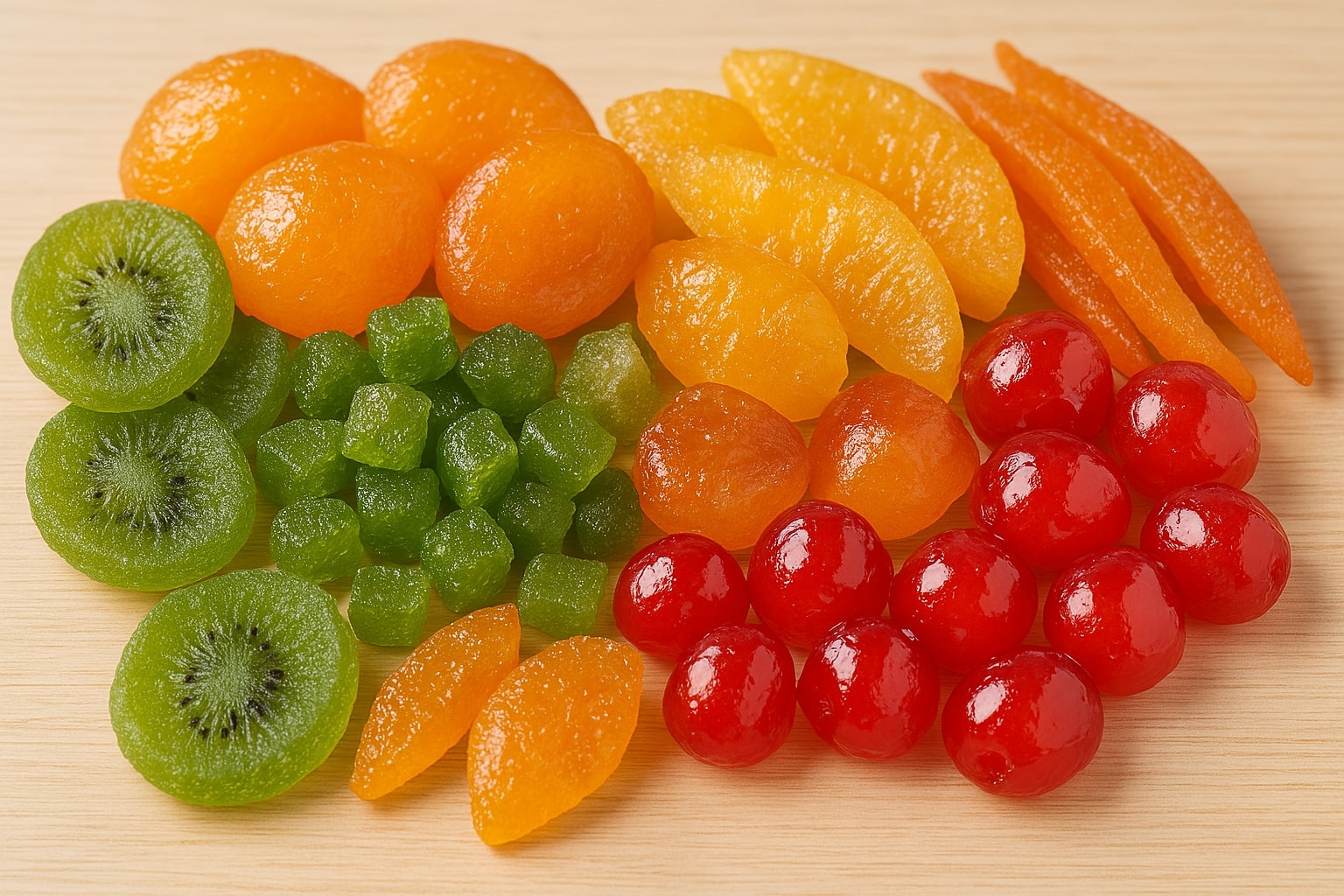

The Pulper Finisher employs a dual-stage assembly, allowing for flexible integration into various production lines. Applications include processing tomato paste, diced and peeled tomatoes, jams, candied fruits, and refined fruit juices. Constructed entirely from stainless steel, it features high-thickness perforated plates for superior durability and corrosion resistance.

For enhanced energy efficiency, this machine includes a variable-speed rotor and an intuitive mechanical setup, ensuring lower operational costs and easier maintenance. Its integrated washing system with internal nozzles supports effective cleaning, reducing downtime and contamination risks. FENCO provides various customization options, including a screw feeder for cold extraction, tailoring the machine’s components to match specific production needs.

Benefits

- Maximizes production efficiency with continuous, high-capacity processing.

- Ensures product purity by effectively separating unwanted impurities.

- Reduces maintenance time with an integrated washing system.

- Lowers operational costs through energy-efficient design and variable-speed control.

- Customizable options to fit specific production requirements.

- Applications

- Fruit products, Jams, Refined juices, Tomato products, Purees, Candied fruits

- End products

- Apple puree, Strawberry jam, Tomato juice, Peach puree, Tomato puree, Raspberry jam, Peeled tomatoes, Candied cherries, Refined apple juice, Refined orange juice, Mango puree, Candied orange peel, Tomato paste, Diced tomatoes, Apricot jam

- Steps before

- Sorting, Washing, Grinding, Milling

- Steps after

- Sterilization, Packing, Concentration, Pasteurization

- Input ingredients

- tomatoes, fruits, skins, peels, seeds, stems

- Output ingredients

- purees, refined juices

- Market info

- FENCO Food Machinery is known for engineering and manufacturing high-quality, customized food processing equipment. Renowned for innovation and reliability, they specialize in designing machinery tailored to specific production needs in the food industry.

- Production Capacity (Tomatoes)

- 5–60 t/h

- Production Capacity (Cold Extraction)

- 3–15 t/h

- Material

- All stainless-steel components

- Stage Options

- Simple or double stage

- Design

- Robust structure and heavy-duty

- Sieve Option

- Perforated plate with high thickness

- Adjustments

- Wide adjustments, rotor turns, and sieve rotor distance

- Feeder Option

- Possibility of screw feeder for cold extraction

- Maintenance

- Optimized mechanics for intuitive maintenance

- Washing System

- Integrated washing system with internal nozzles

- Working Mechanism

- Simple or double stage

- Integrated Steps

- Cold extraction

- Automation level

- Intuitive maintenance

- Cleaning method

- Integrated washing system with internal nozzles

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Integrated washing system

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- Low to medium

- Machine footprint

- Robust structure, adaptable size

- Material composition

- All stainless-steel components

- Operation capacity

- 5 to 60 t/h (tomatoes)

- 3–15 t/h (cold extraction)

- Stage assembly

- Simple or double stage

- Customization options

- Integrated washing system, sieve rotor distance adjustments

- Feed/discharge method

- Possibility of screw feeder for cold extraction

- Stage assembly

- Single or Double

- Integrated washing system

- Internal nozzles