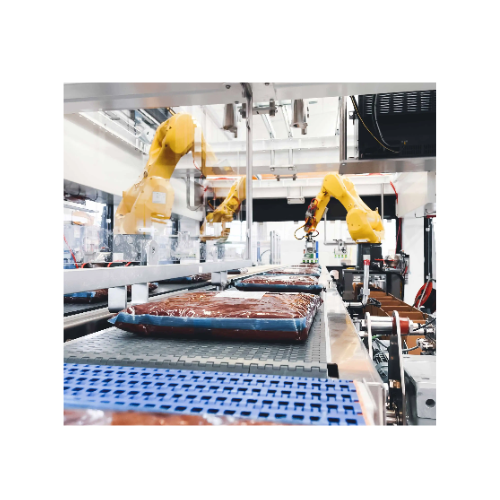

Robotic case packers for bags and pouches

Efficiently pack a variety of bagged and pouched products with precision handling, ensuring optimal carton arrangement and seamless production integration.

Automates Handling and Packing of Diverse Bag Formats

The robotic case packers from CFT Group are engineered to optimize your food packaging line by efficiently automating the handling and packing of diverse bag formats. These systems excel in integrating seamlessly into existing operations, ensuring full automation driven by programmable logic control (PLC) systems. Suitable for processing fruits, sauces, jams, and vegetables, the equipment handles up to 2,400 containers per hour. Utilizing a 3D vision module, it guarantees precise bag placement in different carton styles and includes automatic rejection of non-compliant items. Designed with modularity, additional robots can be integrated, enhancing productivity. The equipment also achieves energy efficiency with automatic head changes and improved motor controls, promoting sustainability with reduced operational costs. Built with safety compliance in mind, all electrical systems are contained within the structure, supporting smooth and reliable performance in demanding environments.

Benefits

- Enhances production efficiency by automating complex packing tasks, reducing manual labor.

- Maximizes throughput with the capacity to handle up to 2,400 containers per hour.

- Promotes energy savings through optimized motor control and automatic head changes.

- Increases flexibility by accommodating multiple bag formats and carton types.

- Ensures product quality with an automatic rejection system for non-compliant bags.

- Applications

- Ketchup, Sauces, Jams, Fruits, Tomato, Vegetables, Bags

- End products

- Tomato paste cartons, Vegetable bags, Sauce packets, Fruit pouches, Jam jars, Diced tomatoes, Ketchup sachets

- Steps before

- Receiving, Washing, Sorting, Chopping, Extracting

- Steps after

- Depalletizing, Palletizing

- Input ingredients

- bags, pouches, different bag formats

- Output ingredients

- carton formats, containers, 2, 400 containers/hour

- Market info

- CFT Group specializes in manufacturing engineered-to-order equipment for the food and beverage industry, renowned for its innovative processing and packaging solutions, focusing on sustainability and advanced technology.

- Capacity

- 2, 400 containers/hour

- Container Type

- Bags

- Maximum Bag Weight

- up to 10 kg

- Automation

- Fully automatic head change

- Recognition System

- Automatic with 3D vision module

- Robot Axis

- 6 axis

- Automation level

- Fully automatic

- Changeover time

- Automatic head change

- Modular structure

- Yes, easily upgradable

- Safety compliance

- Electrical panels contained

- Bag handling

- Simultaneous multiple formats

- Max container capacity

- 2, 400 containers/hour

- Operation type

- Batch

- Weight recognition

- Automatic recognition system

- Handling weight

- Up to 10 kg

- Handling capability

- Bag-In-Box Robot

- Operating sectors

- Fruits, Ketchup, Sauces, Jams, Vegetables, Tomato

- Container type

- Bags

- Safety compliance

- Yes

- Control panel type

- Fully automatic

- Modular structure

- Yes

- Bag weight capacity

- Up to 10 kg

- Automatic head change

- Fully automatic

- Robotic system configuration

- Modular structure

- Multi-format handling

- Simultaneous for different bag formats

- Control system

- Recipe-based automation

- 3D vision system

- Automatic recognition