Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity with our piston filler, ideal for high-speed operations requiring accurate filling of both liquid and slurry products.

Fills and Packages Liquids and Slurries

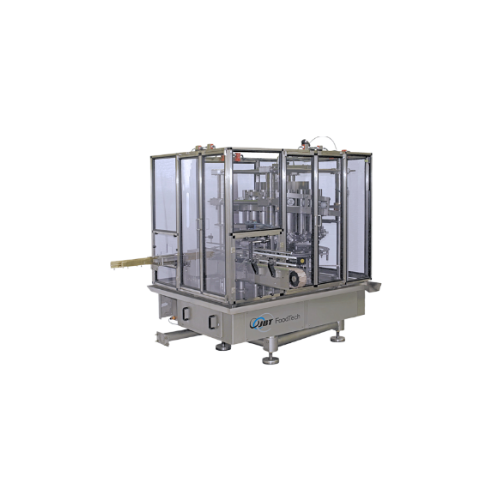

The JBT Piston Filler is a versatile volumetric filling solution designed for seamless integration into various production lines in food, beverage, and industrial sectors. It features a highly accurate system capable of handling both low and high-viscosity liquids, with or without particles, up to 25 mm in size. This piston filler is suitable for a wide array of applications, from infant formula and yogurt to industrial paints and solvents. Its design allows for continuous operation with adjustable fill volume even during use, ensuring minimal downtime and high throughput.

With a full WIP/CIP-compatible guarding and a stainless-steel construction, it offers excellent corrosion resistance and ease of cleaning. The unit is PLC-controlled, providing remote monitoring capabilities for enhanced automation. The replaceable plug valve and piston allow for quick maintenance, reducing service times. JBT ensures the equipment meets strict compliance standards, making it ideal for certified facilities. Customization options are available upon request to tailor the system to specific production demands, supported by JBT’s comprehensive engineering support services.

Benefits

- Maximizes production efficiency with precise volumetric filling, minimizing product waste.

- Enhances flexibility by handling a wide range of viscosities and particles, supporting diverse product lines.

- Reduces maintenance interruptions through easily replaceable components.

- Optimizes cleaning processes with CIP compatibility, ensuring faster turnaround.

- Complies with industry standards, guaranteeing suitability for certified production environments.

- Applications

- Sauces, Oils, Dairy, Seafood, Soups, Dairy alternatives, Industrial products, Seasonings, Juices, Tea, Ready meals, Pet food, Fruits, Nuts, Chemical, Baby food, Beverages, Meat, Coffee, Dressings, Poultry

- End products

- Herb seasoning, Baby puree, Infant formula, Industrial solvents, Nut butter, Orange juice, Almond milk, Dry dog food, Canned tuna, Cold brew coffee, Yogurt, Tomato sauce, Chicken breast pieces, Olive oil, Tea concentrates, Ground beef, Microwave-ready lasagna, Paints, Fruit puree, Frozen chicken curry, Tomato juice, Wet cat food, Adhesives, Chicken soup, Ranch dressing

- Steps before

- Grinding, Mixing, Emulsification, Juicers, Finishers, Extractors

- Steps after

- Packing, Pasteurization, Sterilization, In-Container Sterilization

- Input ingredients

- liquid products, viscous products, products with particles, pumpable products, high viscosity products, low viscosity products

- Output ingredients

- filled glass jars, filled cans, filled plastic containers, filled wide-mouth rigid containers, filled semi-rigid containers

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Filling accuracy

- Highly accurate

- Filling volume

- Infinitely adjustable from zero to maximum full volume

- Viscosity range

- High and low viscosity products

- Particle size capacity

- Up to 25 mm

- Container type

- Wide-mouth rigid or semi-rigid containers such as glass jars, cans, and plastic containers

- Materials

- Stainless steel bottom plate

- Cleaning method

- Compatible with WIP (Wash In Place) and CIP (Clean In Place)

- Plug valve and piston replacement

- Easily and quickly replaceable

- Working mechanism

- Volumetric filling with piston and plug valve

- CIP/SIP compatibility

- WIP/CIP-compatible guarding

- Automation level

- Adjustable fill volume during operation

- Changeover time

- Quick replacement of valve and piston

- Cleanability

- WIP/CIP-compatible

- Viscosity Range

- Low to high viscosity products

- Particle Size

- Up to 25 mm

- Container Type

- Glass jars, cans, plastic containers

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Container size

- Wide-mouth

- Container type

- Rigid/Semi-rigid

- Material

- Stainless steel

- Guarding feature

- WIP/CIP-compatible

- Drainage point

- One single drainage point

- Plug valve and piston replacement

- Easily and quickly replaceable

- Fill volume adjustment

- Infinitely adjustable from zero to maximum full volume

- Machine compatibility

- WIP/CIP-compatible

- Guarding

- Full WIP/CIP-compatible guarding

- Control panel type

- Available upon request

- Integration possibilities

- Available upon request