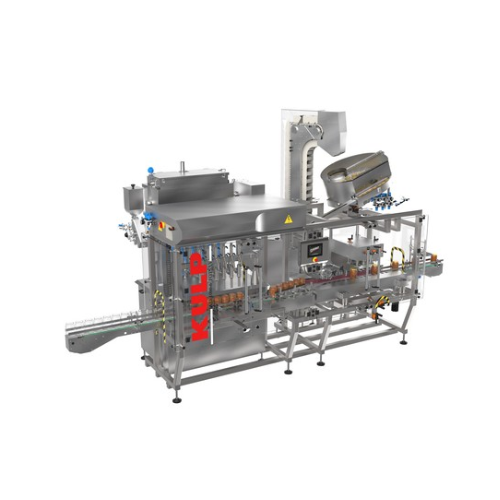

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling and capping into your production line, ensuring accurate packaging for a diverse range of liquid and viscous products.

Fills and Caps Liquid and Viscous Products

The 6 Heads Monoblock from Kulp Makina seamlessly integrates filling and capping functionalities within a compact design. This machine efficiently handles liquids, semi-liquids, and viscous products, making it ideal for diverse industries such as food, cosmetics, and chemicals. With a range of adjustable filling capacities from 50ml to 1000ml, it supports high throughput, processing up to 3600 packages per hour. Equipped with pneumatic and servo-motor options, it ensures precise filling accuracy, ±1%, backed by an anti-dropping system to prevent wastage. The machine is designed for easy integration into production lines with its user-friendly touch screen interface and tri-clamp connections for quick disassembly during cleaning. Materials in contact with products are crafted from 316L stainless steel, ensuring durability and compliance with food hygiene standards. Optional features, including agitators and CIP cleaning systems, offer enhanced flexibility and maintenance efficiency.

Benefits

- Enhances operational efficiency with simultaneous filling and capping, reducing production time.

- Achieves precise product consistency with ±1% filling accuracy, minimizing product waste.

- Adapts to various product viscosities and container types, offering versatile production capabilities.

- Simplifies maintenance with quick-release connections, ensuring minimal downtime during cleaning.

- Complies with stringent hygiene standards, safeguarding product quality and safety.

- Applications

- Viscous products, Household products, Cosmetic products, Biomedical products, Liquid products, Industrial products, Food products

- End products

- Liquid soap refill packs, Anti-freeze solutions, Ketchup bottles, Peanut butter, Glass cleaner spray, Mayonnaise jars, Balsamic vinegar bottles, Cream cheese, Body lotion tubes, Disinfectant sprays, Soup packs, Edible oil containers, Chocolate spread, Tomato paste cans, Fertilizer containers, Hand sanitizer bottles, Engine oil bottles, Pva glue bottles, Shampoo bottles

- Steps before

- Formulation, Mixing, Pre-heating, Homogenization

- Steps after

- Cooling, Labeling, Packaging, Quality Inspection

- Input ingredients

- chocolate spread, peanut butter, hazelnut hash, honey, cream honey, mayonnaise, ketchup, mustards, sauces, jam, marmalade, tomato paste, pepper paste, cream cheese, cheese spread, labne, yogurt, milk, ayran, clotted milk, molasses, vinegar, balsamic vinegar, syrups, pomegranate concentrate, edible oils, pre-cooked meals, American salad, mashed vegetables, tapenade, glaze, toppings, soups, cosmetic oils, cosmetic creams, shampoo, conditioner, liquid soap, bodywash, hair cream, body lotion, peelings, face and body mask, waxes, gels, Vaseline, foundation, BB cream, ointments, lotions, glycerin, disinfectant, biomedical products, sanitary products, veterinary products, paints, glue, PVA, hydrogen peroxide, ink, fertilizers, pesticides, varnish, household products, engine oil, glass cleaner, anti-freeze

- Output ingredients

- filled packages, bottled products, capped products, sealed containers

- Market info

- Automation

- PLC-controlled

- Capacity

- 3000–3600 packages per hour

- Filling accuracy

- ±1%

- Compressed Air Usage

- 6 bars / 800 lt/min

- Filling volume

- 50 ml – 1000 ml

- Operating Temperature

- +5 ºC to +85 ºC

- Electrical Connection

- Three phase (380v / 50-60 Hz)

- Material of Construction

- 316 L and 304 L stainless steel, Anodized aluminium

- Nozzle type

- Interchangeable with anti-dropping system

- Capping Type

- Metal twist-off, plastic screw, push-on

- Conveyor Length

- 3 meters

- Hopper Capacity

- 80 liters

- Working mechanism

- Pneumatic, Electronic

- Integrated steps

- Filling and Capping

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- Optional CIP system

- Automation level

- PLC-controlled

- Changeover time

- Quick nozzle change system

- Cleaning method

- Designed for easy disassembly

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Compact footprint

- Yes

- Control panel type

- Touch Screen

- Discharge method

- Automatic

- Adjustable side rails

- Yes, for varied sizes

- Control Panel Type

- Touch Screen Interface

- Volume Adjustment Method

- Handwheel and Numerator

- Nozzle Type

- Interchangeable for Liquids and Viscous Products

- Capping Head Type

- Easy Change for Different Caps

- Diving Nozzle Speed

- Adjustable for Foamy Products

- Hopper Type

- Optional Double Jacketed Hopper

- Cleaning System

- Optional C.I.P. Suitable

- Agitator

- Optional

- Filling Piston Cleaning System

- Optional Back Side Cleaning