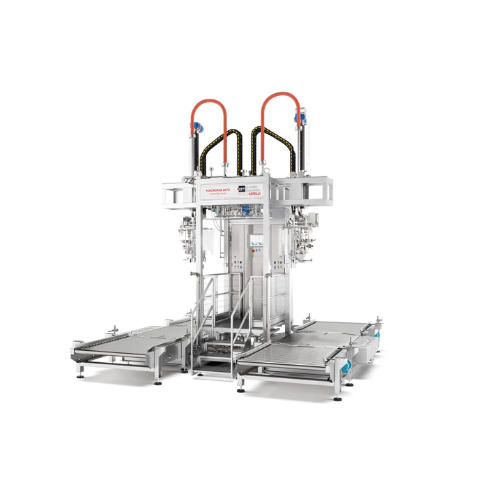

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adaptable machines that maintain product integrity across various packaging formats, enhancing efficiency and precision in your production line.

Fills and Sterilizes Liquid and Slurry Products

CFT Group’s Minipak, Aseptic Magnum, Macropak RVS, Macropak MF, Macropak AF, and Labopak aseptic filling machines offer tailored solutions for seamless integration into food and beverage processing lines. These machines specialize in filling and sterilizing liquid and slurry products, ensuring precise dosing and maintaining product integrity. They cater to a diverse range of applications, including fruit purees, UHT milk, tomato paste, and sauces.

The aseptic filler range incorporates state-of-the-art technology with flexible packaging options, handling capacities ranging from 5 to 1,000 liters per bag, and achieving speeds of up to 500 bags per hour with low viscosity products. They integrate smoothly with existing processing and packaging setups, featuring remote monitoring capabilities via VPN and advanced PLC controls.

Available with robust materials such as stainless steel, these machines stand up to the challenges of handling high-acidity products while ensuring compliance with FDA standards. Enhanced cleaning capabilities, including steam washing and CIP options, facilitate maintenance and minimize downtime, while customizable features meet specific production needs, offering a competitive edge in modern production environments.

Benefits

- Ensures product safety and integrity with aseptic filling, reducing contamination risks.

- Enhances flexibility with versatile bag and spout configurations, catering to varied production demands.

- Boosts operational efficiency with high-speed filling, maximizing throughput up to 500 bags per hour.

- Minimizes maintenance time through integrated steam-based cleaning systems.

- Optimizes resource utilization with energy-efficient designs and remote monitoring capabilities.

- Applications

- Other foods, Ketchup, Sauces, Milk, Jams, Fruits, Tomato, Vegetables, Edible oil, Dairy

- End products

- Cream, Applesauce, Olive oil, Uht milk, Sorbets, Fruit purees, Salad dressings, Cream cheese, Yoghurt, Condensed milk, Fruit preserves, Tomato paste, Vegetable purees, Soup bases

- Steps before

- Receiving, Washing, Sorting, Peeling, Chopping, Extracting, Enzymatic inactivation, Evaporating, Sterilizing

- Steps after

- Packing, Seaming, Robotic handling, Robotic case packing, Depalletizing, Palletizing

- Input ingredients

- fruits, milk, dairy, tomato, vegetables, sauces, jams, edible oil, liquid foods, viscous foods, fiber-containing products, particulate-laden products

- Output ingredients

- aseptic bags, drums, bins, pouches, small bags, drum bags, aseptic pouches

- Market info

- CFT Group specializes in manufacturing engineered-to-order equipment for the food and beverage industry, renowned for its innovative processing and packaging solutions, focusing on sustainability and advanced technology.

- Filling speed

- Up to 500 bags per hour

- Filling volume

- 5 liters/bag to 1, 000 liters/bag

- Dosing device passage

- 1" integral passage

- Dosing device passage

- 2" integral passage

- Dosing device passage

- 3" integral passage

- Container type

- Bags

- Remote monitoring

- Via VPN

- Validation

- Optional FDA validation test

- Automation level

- PLC / Remote monitoring via VPN

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Steamjet/condensate washing

- Cleaning method

- Steam washing

- Compact design

- Reduced footprint suitable for small-medium workshops

- Filling system configuration

- Pneumatic cylinder and head translation system

- Dosing passage size

- 1", 2", and 3" integral passage for different product viscosities

- Bag size compatibility

- 5-20 liters or up to 1, 000 liters

- Filling head

- Single and dual head configurations

- Control panel type

- Touchscreen HMI / PLC

- Compact footprint

- Yes

- Dosing device size

- 1’’ - 3’’ integral passage

- Remote monitoring

- Via VPN

- Head design

- Single / Two-head

- Bag size range

- 5 liters - 1, 000 liters

- Filling capacity

- Up to 500 bags/hour

- Spout washing

- Steamjet/condensate

- FDA validation test

- Optional