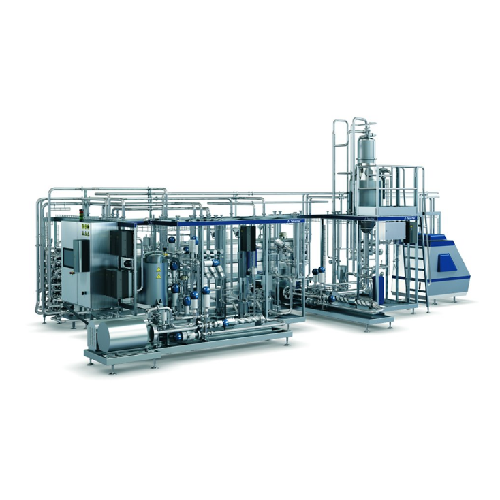

Food pasteurizer for prepared foods

Optimize your prepared food production with precise temperature control and automated operations, reducing waste and accelerating product launches.

Processes and Pasteurizes Prepared Food Products

The Tetra Pak® Pasteurizer PFC is a highly versatile solution tailored for food manufacturers aiming to optimize their pasteurization processes. This equipment offers flexible heat exchanger configurations, accommodating both high and low viscous liquid and slurry products, ensuring accurate heat treatment up to 140°C. It’s ideal for producing tomato ketchup, concentrated tomato paste, teriyaki sauce, and smooth desserts like chocolate pudding. With a capacity ranging from 3,000 to 30,000 liters per hour, it efficiently handles diverse prepared food applications.

The automated system significantly reduces product waste by precisely controlling the emptying and filling processes, potentially saving manufacturers between €17,000 and €35,000 annually with four product changes. Its modular design accelerates product line introductions by 20%, minimizing time-to-market.

The equipment supports different automation levels, from stand-alone monitoring of temperatures and flows to full line integration via Tetra PlantMaster, enhancing production insights and operational control. The Tetra Pak® Pasteurizer PFC is engineered to offer low total cost of ownership with robust guarantees, making it a future-proof investment for continuous and automated food processing operations.

Benefits

- Significantly reduces product waste and costs with precise automated filling and emptying functions.

- Accelerates new product introduction by 20% with modular design, reducing time-to-market.

- Provides flexible processing capabilities for various product viscosities with adaptable heat exchanger configurations.

- Optimizes operational insights and control through customizable automation levels according to production needs.

- Ensures energy-efficient processing with high throughput capacity, lowering energy usage per unit produced.

- Applications

- Ketchup, Sauces, Soups, Smooth desserts, Fruit preparations, Tomato paste, Prepared foods, Soy sauces

- End products

- Teriyaki sauce, Vegetable broth, Strawberry jam, Cream of mushroom soup, Concentrated tomato paste, Chocolate pudding, Marinara sauce, Tomato ketchup

- Steps before

- Mixing, Blending, Cooking, Homogenization

- Steps after

- Cooling, Filling, Sealing, Packaging

- Input ingredients

- Ketchup, Tomato paste, Soy sauces, Smooth desserts, Fruit preparations, Prepared foods

- Output ingredients

- Pasteurized ketchup, Pasteurized tomato paste, Pasteurized soy sauces, Pasteurized smooth desserts, Pasteurized fruit preparations, Pasteurized prepared foods

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 3, 000 - 30, 000 l/h

- Temperature treatment

- up to 140°C

- Heat exchanger type

- Flexible (Tubular and Plate)

- Automation

- Flexible degree (Stand-alone/Full line)

- Product waste reduction

- between €17, 000 – 35, 000 per year

- Product change savings

- 4 product changes

- Commissioning time reduction

- up to 20%

- Batch vs. continuous operation

- Inline Continuous

- Flexible heat exchanger set-up

- Plate / Tubular

- Automation level

- Stand-alone / Full line / Factory site integration

- Automated filling and emptying

- Yes

- Modular equipment design

- Shortened lead times

- Energy efficiency

- Cost-effective

- Changeover flexibility

- Fast changeover

- Viscosity

- Low to high viscous products

- Heat sensitivity

- Up to 140°C

- Product type

- Ketchup, tomato paste, soy sauces, smooth desserts, fruit preparations

- Container size

- Efficient for 3, 000 - 30, 000 l/h

- Foaming potential

- Automated emptying reduces product waste

- Heat exchanger type

- Tubular / Plate

- Heat exchanger configuration

- Flexible

- Automation level

- Flexible / Modular

- Filling method

- Automated / Optimized

- Discharge method

- Automated

- Heat exchanger set-up

- Flexible

- Degree of automation

- Flexible, depending on customer's needs

- Modular design

- Speeds up new product introduction by 20%

- Factory integration

- Tetra PlantMaster