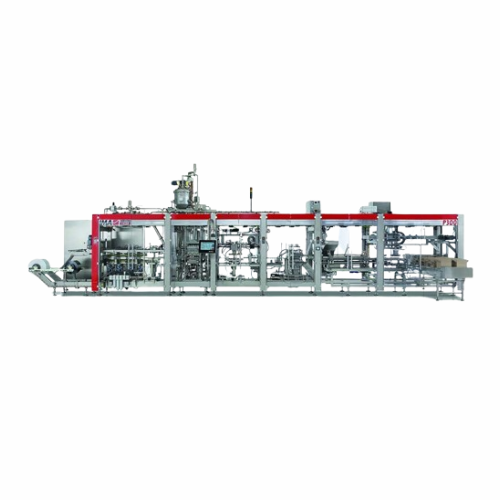

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently forms, fills, and seals, ensuring hygienic standards while minimizing downtime and operational costs. Ideal for diverse food and dairy applications requiring precise and high-output solutions.

Forms, Fills, and Seals Portion Packs

The P300 from IMA Group is a compact, modular form fill seal machine specifically designed for portioning liquid products like sauces, dressings, and dairy items. Its standout feature is the minimal footprint and modular design, allowing seamless integration into existing production lines for food and dairy applications. With a throughput of 22,000 to 54,000 portion packs per hour, it efficiently processes a variety of cup shapes and sizes. The P300’s sophisticated servo motor control system ensures precise product cut-off and minimal downtime while maintaining high hygiene standards through automatic SIP/CIP systems. It supports clean, ultra-clean, and aseptic processing in compliance with FDA and other international standards. Built for easy maintenance with low operational costs, the machine also offers customizable options such as hot fill accessories and multiple web handling configurations.

Benefits

- Enhances productivity with a high throughput of up to 54,000 portion packs per hour.

- Minimizes operational costs with an energy-efficient servo motor system.

- Maintains hygiene and product integrity with automatic SIP/CIP systems and aseptic processing.

- Offers flexibility with customizable configurations for different cup shapes and sizes.

- Facilitates seamless production line integration with a compact, modular design.

- Applications

- Food, Ketchup, Sauces, Spreads, Jams, Cream cheese, Soft cheese, Desserts, Dressings, Butter, Mayonnaise, Honey, Mustard, Dairy

- End products

- Chocolate mousse, Balsamic vinaigrette, Ricotta cheese, Liquid honey, Dijon mustard, Mango mousse, Caesar dressing, Sour cream, Chipotle sauce, Hazelnut spread, Mascarpone cheese, Gourmet mayonnaise, Herb cream cheese, Bee honey, Fruit jams, Raspberry jam, Unsalted butter, Whipped cream desserts, Salted butter

- Steps before

- Bottom web feed, Bottom web sterilisation, Pre-heating, Thermoforming

- Steps after

- Cup conveyor discharge, Case packing, Carton infeed, Carton loading

- Input ingredients

- PET, PP, PP multilayer, PLA, PS, PS multilayer, PVC, Paper-based lid material, Aluminium-based lid material, PET-based lid material, Heat sealable materials

- Output ingredients

- butter, desserts, cream cheese, soft cheese, ketchup, mustard, mayonnaise, sauces, jams, honey, spreads, dressings

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Speed

- 22.000 – 54.000 cups/h

- Footprint

- Small

- Web level height

- Reduced

- Forming depth

- max. 40 mm

- Material width

- max. 340 mm

- Draw-off length

- max. 340 mm

- Automation

- SCHNEIDER ELECTRIC or Rockwell Automation

- Punching principle

- Low waste, multi, grid

- Reel diameters

- Bottom web

- Hygiene class

- Clean (VDMA I + II)

- Material compatibility

- PET, PP, PP multilayer, PLA, PS, PS multilayer, PVC

- Lid materials

- Paper-, aluminium-, PET-based or other heat sealable materials

- Working mechanism

- Form, fill, and seal process

- Integrated steps

- Portioning, sealing, and packaging

- CIP/SIP

- Automatic, fully controlled SIP/CIP systems

- Automation level

- Intuitive HMI, PLC-controlled

- Batch vs. continuous operation

- Continuous operation

- Energy efficiency

- Low operational costs

- Changeover time

- Minimal downtime

- Web level height

- Reduced for convenient handling

- Cleaning method

- Automatic SIP/CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Portion cups

- Filling purpose

- Butter, desserts, cream cheese, soft cheese, etc.

- FDA Aseptic

- Available on demand

- 3A Sanitary Standards

- Available on demand

- EHEDG certification

- Available on demand

- European regulations

- Full compliance

- Compact footprint

- Small footprint

- Modular structure

- Modular design

- Web level height

- Low for improved ergonomics

- Footprint

- Small

- Control panel type

- Simple, intuitive HMI

- Web level height

- Reduced for improved ergonomics