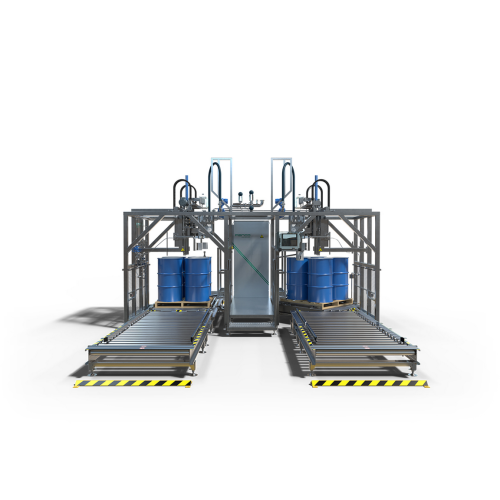

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precise filling and sterilization of liquid, viscous, and chunky products, maintaining product integrity and extending shelf life.

Fills, Sterilizes, and Packages Food Products

Fenco’s Industrial Aseptic Filling Machine excels in filling, sterilizing, and packaging a variety of food products, including liquid, viscous, and chunky items. Designed for 24/7 operation, this machine offers total process control with options for steam or disinfectant cap sterilization. It’s FDA-certifiable, suiting food processing companies that demand high hygiene standards. Capable of handling low and high pH products, it effectively manages products like tomato paste, jams, sauces, and dairy liquids. With its easy-clean design and limited part numbers, maintenance is streamlined. Integration is seamless, with storage for historical plant data and personnel interventions, ensuring traceability and efficiency in production lines. Ideal for continuous, high-speed operations across food, dairy, and beverage industries.

Benefits

- Enhances production efficiency with continuous operation.

- Ensures product safety through sterilization and FDA certification options.

- Simplifies cleaning and maintenance, minimizing operational disruptions.

- Supports diverse product ranges, increasing production flexibility.

- Provides comprehensive data logging for improved process traceability.

- Applications

- Liquid formulations, Milk products, Formulated products, Fruit products, Viscous products, Chunky products, Tomato products

- End products

- Smoothies, Flavored milk drinks, Tomato juice, Pureed soups, Tomato puree, Jams, Dairy liquids, Peeled tomatoes, Fruit nectars, Pasta sauce, Yogurt-based drinks, Fruit concentrates, Tomato paste, Candied fruits, Diced tomatoes, Salsa

- Steps before

- Formulating, Processing, Pasteurization

- Steps after

- Sterilization, Packing

- Input ingredients

- liquid products, viscous products, chunky products

- Output ingredients

- small bags, 200l drums, 1000l bags

- Market info

- FENCO Food Machinery is known for engineering and manufacturing high-quality, customized food processing equipment. Renowned for innovation and reliability, they specialize in designing machinery tailored to specific production needs in the food industry.

- Bag size

- 3 to 1000 L

- Filling head options

- Mono and bi-head

- Product type compatibility

- Liquid, viscous, and chunky products

- PH range compatibility

- Low pH and high pH

- Sterilization method

- Steam or disinfectant

- Capacity ranges

- Small and medium productions

- Automation

- Total process control

- Operation duration

- 24/7 operation

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Ease of use

- High

- Process control

- Total control in filling and sterilization phase

- Product capacity

- Small bags

- Drums

- 200L

- Bags

- 1000L

- Product versatility

- Liquid, viscous, and chunky products

- CIP/SIP

- Easy-clean design

- Sterilization method

- Steam or disinfectant, depending on product

- Operating time

- 24/7 operation

- Data storage

- Plant history and process parameters

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bag size

- 3 to 20l, 200l drums, 1000l bags

- Head configuration

- Mono and bi-head

- Machine footprint

- Compact footprint for small and medium productions

- Feed/discharge method

- Sterilization of the cap with steam or disinfectant

- Control panel type

- Easy-clean design with process control

- Control panel type

- Touchscreen / Button

- Compact footprint

- Yes

- Integration possibilities

- SCADA / PLC systems

- Discharge method

- Gravimetric / volumetric

- Customization for product types

- Liquid / Viscous / Chunky

- Drive system

- Servo / Pneumatic

- Head configuration

- Mono-head / Bi-head