Industrial evaporators for multi-product processing

Optimize your production line with customized evaporators designed for efficient processing of viscous and delicate products, ensuring energy savings and seamless operation across a variety of applications.

Evaporates and Recompresses Liquid and Slurry Products

The Hybrid Evaporator, designed by Fenco Food Machinery, efficiently processes a range of liquid and slurry products, catering to food and waste processing industries. By combining forced circulation, falling film, and thin-layer technologies, it spans applications from concentrated tomato paste to evaporated milk. Its capacity ranges from 5,000 to 70,000 liters per hour. Featuring Thermal and Mechanical Vapor Recompression, it optimizes steam usage and minimizes energy consumption. The evaporator integrates PLC control and remote monitoring, ensuring seamless automation and operation. Constructed with robust materials, it can be customized for corrosion resistance and includes a self-diagnostic system for maintenance ease. Aroma-recovery options enhance product quality, and it supports a high degree of integration into existing production lines.

Benefits

- Minimizes energy costs with efficient vapor recompression technologies.

- Prolongs production periods with reduced downtime through optimized exchanger design.

- Cuts cleaning expenses and downtime with quick CIP capabilities.

- Ensures operational reliability and responsiveness with remote monitoring and self-diagnostics.

- Provides versatile processing, enabling multiple product types within the same setup.

- Applications

- Milk products, Fruit products, Waste products, Tomato products, Residues

- End products

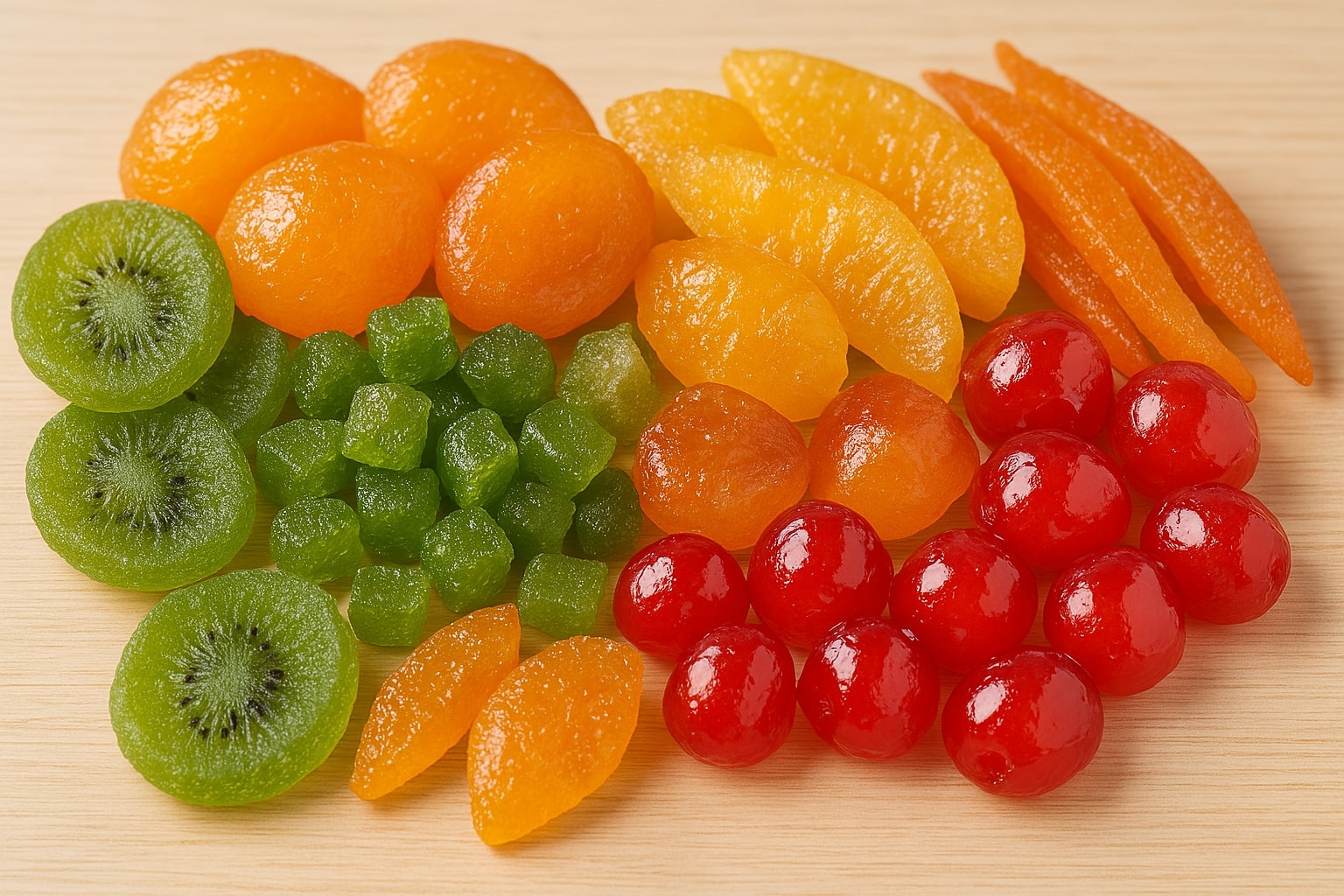

- Double-concentrated tomato paste, Tomato juice, Tomato puree, Jams, Peeled tomatoes, Evaporated milk, Tomato paste, Candied fruits, Diced tomatoes

- Steps before

- Filtration, Pulping, Clarification, Blending

- Steps after

- Cooling, Aroma Recovery, Decanting, Packing

- Input ingredients

- fruit, tomatoes, milk, processing residues, waste products

- Output ingredients

- evaporated water, sauce, double-concentrated tomato paste

- Market info

- FENCO Food Machinery is known for engineering and manufacturing high-quality, customized food processing equipment. Renowned for innovation and reliability, they specialize in designing machinery tailored to specific production needs in the food industry.

- Evaporation Capacity

- 5, 000 to 70, 000 l/h

- Evaporation Type

- Forced circulation / Falling film / Turbulent, thin-layer

- Steam Optimization

- Thermal Vapor Recompression (TVR) / Mechanical Vapor Recompression (MVR)

- Energy Consumption

- Low energy consumption

- Automation

- High degree, remote control capability

- Operation Management

- Touch panel, software, and settable parameters

- Multi-product Capability

- Process various products in the same plant

- Aroma Recovery System

- Optional

- Production Time

- Prolonged between washes

- Wash Times

- Reduced

- Working Mechanism

- Forced Circulation / Falling Film / Turbulent Thin-Layer

- Integrated Steps

- Hybrid Solutions

- Energy Efficiency

- Low Energy Consumption

- Cleaning Method

- Optimized CIP Design

- Batch vs. Continuous Operation

- Multi-product Capability

- Automation Level

- High Degree of Automation / Remote Control

- Changeover Time

- Reduced Wash Times

- Automation Features

- Self-diagnostics of Sensors and Motors

- Touch Panel Control

- Easy to Use, Settable Parameters

- Process Versatility

- Capable of Processing Various Products

- Aroma Recovery System

- Integration Available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank shape

- Rectangular / Cylindrical

- Tank size

- Customizable

- Feed method

- Pump-fed / Gravity-fed

- Discharge method

- Gravity / Pump

- Control panel type

- Touch panel

- Integration possibilities

- Remote control, aroma-recovery system

- Automation level

- High degree of automation

- Self-diagnostics

- Sensors and motors