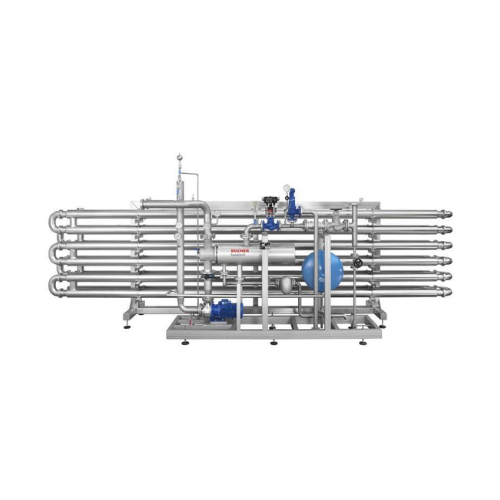

Mash heater for core fruits and berries

Improve juice extraction and color yield in your fruit processing line with this innovative mash heating solution, designed to optimize enzyme activation and streamline the preheating process.

Enhances Juice and Color Yield

The Mash Heater from Bucher Unipektin offers a specialized solution for enhancing juice extraction and color yield in fruit and berry processing. Employing a pipe-in-pipe tubular design, this system ensures gentle heating of fruit mash, activating enzymes and improving yield without compromising quality. Situated between the milling and mash holding sections, the mash heater processes up to 120 tons per hour with a capacity range of 700–2,800 kW. The modular system uses a hot water or optional low-pressure steam heating system, operating within a temperature range of 5 to 85°C. Automation is facilitated by PLC-based controls with touchscreen visualization, allowing for continuous operation and easy integration into existing lines. The robust construction supports varied and adaptable processing needs, offering customizable sections based on output requirements. Maintenance is straightforward, with an easy-to-clean design and hot water recirculation for efficient system management.

Benefits

- Increases juice yield and color extraction through efficient enzyme activation.

- Minimizes heat impact, preserving fruit quality with gentle processing.

- Enhances operational flexibility with adjustable hot water temperatures.

- Reduces labor costs and streamlines operations with automated PLC-based control.

- Easily integrates into existing production lines with compact, modular design.

- Applications

- Berry processing, Fruit processing, Food processing, Juice extraction, Juice and color yield enhancement

- End products

- Berry syrup, Apple juice, Stone fruit puree, Pear nectar, Berry compote, Fruit concentrate

- Steps before

- Milling, Grinding

- Steps after

- Mash Holding, Juice Extraction, Color Extraction

- Input ingredients

- fruit mash, apples, pears, berries, stone fruits

- Output ingredients

- heated mash, extracted juice, improved colour yield

- Market info

- Bucher Unipektin is known for producing advanced equipment and systems for the food and beverage industry, specializing in juice processing and filtration technologies with a reputation for innovative solutions and reliable, high-quality products.

- Tube Design

- Pipe-in-pipe tubular design

- Heating Method

- Gentle heating

- Design

- Compact and modular

- Control System

- Automated PLC based

- Cleanability

- Easy to clean

- Enzyme Activity Enhancement

- Yes

- Heat System

- Hot water or low pressure steam

- Capacity

- 10 to 120 t/h, 700–2, 800 kW

- Temperature Range

- 5 to 85 °C

- Number of Sections

- Variable depending on output

- Heat Exchanger Module

- Double tube

- Heating Mechanism

- Pipe-in-pipe tubular design

- Automation level

- PLC-based, visualisation with touchscreen

- Temperature Range

- 5 to 85 °C

- Flow Type

- Inline Counter-current

- Capacity Adjustment

- 10 to 120 t/h

- Heat Transfer Method

- Hot water or low-pressure steam

- Cleaning Method

- Easy to clean

- Batch vs. Continuous Operation

- Inline Continuous

- Hot Water Recirculation

- Yes

- Safety Features

- Safety valve and expansion tank

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- 3A Sanitary Standards

- Not specified

- EHEDG certification

- Not specified

- FDA compliance

- Yes

- FDA materials

- Yes

- CE marking

- Yes

- GMP Compliance

- Yes

- ATEX certification

- Not specified

- Machine footprint

- Compact and modular design

- Design

- Pipe-in-pipe tubular

- Section configuration

- Multi-section system

- Installation location

- Between milling and mash holding

- Modular configuration

- Yes

- Pipe Components

- Preassembled pipe elements

- Safety,Expansion Features

- Safety valve and expansion tank

- Heating method

- Gentle heating

- Control panel type

- PLC-based touchscreen

- Automation level

- PLC / Visualisation

- Capacity adjustments

- Flexible for various fruit types

- Temperature range

- Adjustable 5 to 85 °C

- Heating system

- Hot water / Low pressure steam (optional)

- Number of sections

- Variable