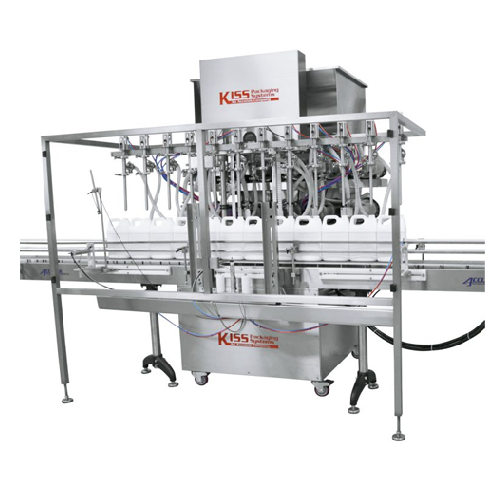

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operations with a solution designed to handle everything from thin liquids to thick pastes, ensuring accurate fills and reducing spillage across various product types and container sizes.

Fills Liquid Products with Precision and Speed

The APD Series Positive Displacement Filling Machine, part of Accutek’s renowned lineup, is designed to tackle diverse liquid handling needs with precision. Utilizing advanced PLC controls and a color touch screen interface, it ensures accurate fills by fine-tuning the flow and speed for each filling head. This machine excels in automatic filling operations, capable of managing liquids from thin juices to viscous sealants, making it versatile across industries such as food, pharmaceuticals, and chemicals. The APD Series features upsurge fill cycles to minimize splashes and includes options for 4gpm to 10gpm pump heads, catering to a range of container sizes and product volumes. Built with sanitary stainless steel and equipped with features like star wheel indexing and a 10-foot variable speed conveyor, it integrates seamlessly into high-speed production lines while offering easy cleaning and maintenance. Customizable options, such as diving heads and positive off nozzles, further enhance its adaptability for specific application needs.

Benefits

- Enhances operational efficiency with precise filling accuracy, minimizing product waste.

- Versatile application across multiple industries, from food to personal care, expanding market possibilities.

- Reduces labor costs with automated indexing and quick changeover capabilities.

- Built in compliance with sanitary standards, supporting hygienic production environments.

- Allows for seamless integration with existing production lines, improving workflow continuity.

- Applications

- Household cleaners, Beverages, Sauces, Sealants, Liquid formulations, Personal care products, Detergents, Nutraceuticals, Varnish, Oils, Cosmetics, Adhesives, Food products, Industrial chemicals, Paints, Dairy products, Pharmaceuticals

- End products

- Super glue, Shampoos, Protein shakes, Cough syrups, Salad dressings, Facial creams, Tomato paste, Essential oils, Wood varnishes, Yogurt drinks, Engine coolants, Automotive paints, Laundry detergents, Antibiotic syrups, Silicone sealant, Fruit juices, Liquid soaps

- Steps before

- Product Mixing, Emulsification, Ingredient Preparation

- Steps after

- Capping, Labeling, Packaging, Inspection, Sterilization

- Input ingredients

- water, juices, vitamin drinks, syrups, dressings, milk, honey, mayonnaise, cheese, jellies, perfumes, hair conditioner, liquid soap, shampoo, creams, lotion, hand wash, body wash, hair styling gels, mascara, eye liner, makeup remover, detergents, oils, liquid cleaners, paint, degreasers, engine coolant, varnish, candles, sealants, grease, glue, silicone, cough medicine, iodine, saline solutions, insect repellent

- Output ingredients

- filled containers, bottled products, packs

- Market info

- Accutek is known for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in custom automation and packaging solutions. They are reputed for their innovation, reliability, and ability to meet complex industrial needs.

- Speed

- Up to 200 CPM

- Fill Size

- 0.5 oz – 5+ gal.

- Viscosity Range

- 1-18000 cp

- Foamy Product Capability

- Yes

- Corrosive Product Capability

- Yes

- Heated Product Compatibility

- Yes

- Particulates Handling

- Yes

- Electrical Requirements

- 220/240 VAC / 3 Phase / 40 Amp

- Air Requirements

- 120psi @ 6 – 12 cfm

- Automation

- PLC-controlled

- Dimensions

- 96" H x 128" L x 48" W

- Weight

- ~1800 lbs. (816.46 kg)

- Automation level

- Automatic / PLC-controlled

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- Manual cleaning with quick clean connection

- Energy efficiency

- No specific value provided

- Cleaning method

- Manual, with possibility of quick clean

- Air incorporation control

- Upsurge fill cycle to reduce splash

- Height adjustment

- Individual height adjustment of fill heads

- Star wheel indexing

- Included

- Viscosity Range

- 1-18000 cp

- Foaming Products

- Yes

- Corrosive Products

- Yes

- Heated Products

- Yes

- Particulates

- Yes

- Container Size

- 0.5 oz – 5+ gal

- Machine Footprint

- 96" H x 128" L x 48" W

- Weight

- ~1800 lbs. (816.46 kg)

- Height Adjustable Frame

- Yes

- Conveyor

- 10' Stainless steel 4.5" wide variable speed conveyor

- Nozzle Count

- Four (4) to twelve (12) fill nozzles

- Frame

- Heavy-duty sanitary stainless steel

- Control Panel Type

- Color touch screen displays

- Feet

- Four height-adjustable, articulating feet

- Movement Option

- Optional heavy duty, locking casters

- Control panel type

- Touch screen with PLC

- Height adjustable

- Yes

- Articulating feet

- Yes

- Upgradable features

- Heavy duty, locking casters

- Container size compatibility

- Wide range

- Nozzle options

- 4 to 12 fill nozzles

- Indexing system

- Star wheel indexing

- Sanitary construction

- Stainless steel

- Conveyor length

- 10’ long variable speed

- Pump head options

- 4gpm (10gpm optional)

- Filtration compatibility

- Universal nozzle assembly

- Application specific pump heads

- Available

- Filling head height adjustment

- Individual adjustment available