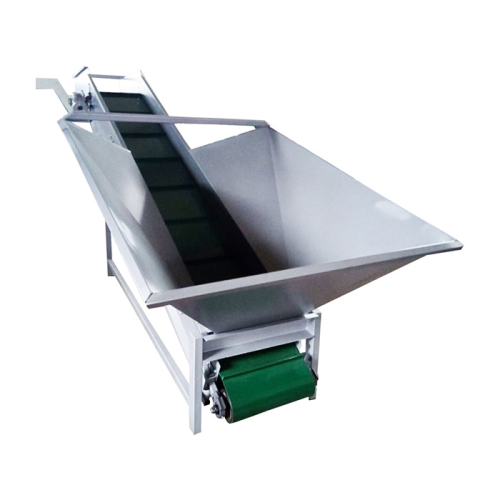

Receiving hopper for jumbo boxes

Efficiently unload and handle bulk agricultural products with ease, streamlining your pre-processing operations for fruits and vegetables.

Receives and Separates Bulk Produce Efficiently

The Receiving Hopper from Kronitek is designed for food processing and agricultural industries, offering efficient management of bulk produce and raw materials. This hopper effectively receives products from jumbo boxes, integrating seamlessly into pre-processing stages with adjustable features for soil separation and conveyor alignment. With a capacity of 1.5 m³ and a 50 cm wide belt, it accommodates a variety of solid items, including vegetables, fruits, and pet food mixes. The inclusion of an optional inverter allows precise belt speed adjustments, while the soil separator can be tailored with a fixed or adjustable span and individual motor control for each roller. It handles loads up to 600 kg and operates at 1.5 kW power. The hopper’s design supports manual and configurable operations, making it suitable for diverse production environments such as industrial food processors, vegetable processing plants, and pet food manufacturers. Adjustable height settings and mechanical separator angle adaptation further enhance its versatility, ensuring compatibility with various upstream and downstream equipment configurations.

Benefits

- Enhances productivity by seamlessly integrating receiving and separation into the production line.

- Offers customizable motor control to optimize processing speed and efficiency for varied materials.

- Minimizes labor costs through adjustable automated settings tailored to specific operational needs.

- Accommodates a broad range of bulk produce with flexible size, height, and angle configurations.

- Supports diverse industry applications from food processing to pet food production with robust construction.

- Applications

- Pet food, Fruits, Agricultural products, Food processing, Vegetables

- End products

- Pre-washed potatoes, Sliced onions, Apple slices, Pet food mix, Pre-packaged vegetables, Fruit salad, Mushroom slices, Diced carrots, Grated cheese, Potato chips

- Steps before

- Unloading, Sorting, Washing

- Steps after

- Soil Separation, Packing, Transporting

- Input ingredients

- jumbo boxes, vegetables, fruits

- Output ingredients

- transported goods, processed vegetables, processed fruits

- Market info

- Container capacity

- 1.5 m³

- Belt width

- 50 cm

- Belt dog height

- 5 cm

- Dimensions (L/W/H)

- 305x215x190 cm

- Weight

- 600 kg

- Installed power

- 1.5 kW

- Power supply

- 3x380V

- Height adjustment range

- 96-130 cm

- Soil separator span adjustment

- 10-70 mm

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Easy to clean surfaces

- Corrosive resistance (e.g. acids)

- Withstands mild acids

- Density/particle size

- Suitable for varied densities of fruits/vegetables

- Machine footprint

- 305x215x190 cm

- Container capacity

- 1.5 m³

- Belt width

- 50 cm

- Belt height

- 5 cm

- Height adjustment range

- 96-130 cm

- Weight

- 600 kg

- Discharge method

- Belt conveyor

- Inverter for hopper belt adjustment

- Yes/No

- Soil separator width adjustment

- 10-70 mm

- Motor independent control for each roller

- Yes/No

- Adjustable separator angle

- Yes/No

- Height adjustment range

- 96-130 cm

- Tipper positioning direction

- From sides/straight-ahead