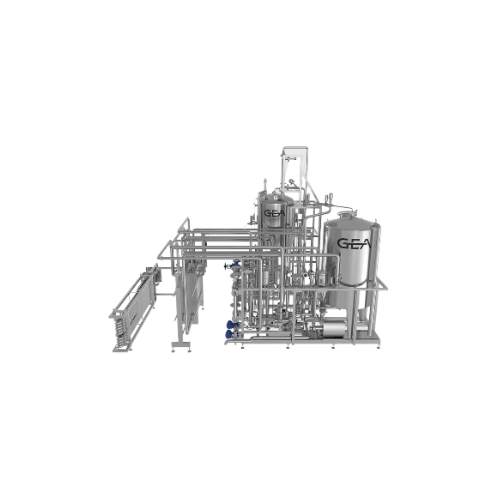

Pasteurizer for non-alcoholic beverages

Ensure microbiological safety and extend shelf life of your non-alcoholic beverages with a versatile pasteurization system designed for seamless integration into your production line, delivering energy-efficient heating, filling, and cleaning processes.

Ensures Safe Pasteurization and Efficient Heat Recovery

The GEA Pasteurizer Systems provide beverage producers with a versatile solution for pasteurizing non-alcoholic beverages. This system is engineered to accommodate diverse liquid products, such as fruit juices and smoothies, with its flexible and continuous processing capabilities. Featuring advanced plate and tubular heat exchangers, the system achieves up to 95% heat recovery, enhancing energy efficiency and lowering operational costs.

GEA’s pasteurization systems are PLC-controlled, allowing seamless integration into existing production lines with options for remote monitoring. This automation supports fast and frequent product switches, ideal for rapidly changing markets. Designed for hygienic operations, the system includes an easy-to-maintain CIP system that ensures thorough and quick cleaning.

Applicable across the food, beverage, and dairy industries, the system adapts to various production needs, from high-speed pasteurization to precise heat management. Constructed with high-grade materials for durability and chemical resistance, it is available in configurations compliant with industry standards, supporting sustainable and reliable beverage processing.

Benefits

- Increases energy efficiency with up to 95% heat recovery, reducing operational costs significantly.

- Enhances production flexibility with rapid product changeovers and continuous operation.

- Ensures product safety and quality through precise pasteurization control, meeting industry standards.

- Minimizes maintenance downtime with easy-to-clean CIP system, improving overall productivity.

- Supports sustainability goals by integrating heat pumps for potential 100% heat recovery, lowering carbon footprint.

- Applications

- Smoothies, Water-based drinks, Non-alcoholic beverages, Beverage concentrates, Fruit juices, Vegetable drinks

- End products

- Herbal water, Apple juice, Tomato juice, Berry smoothie, Orange juice, Mango concentrate, Carrot juice, Lemonade concentrate, Almond milk smoothie, Flavored water

- Steps before

- Ingredient selection, Juicing, Blending, Ingredient mixing

- Steps after

- Filling, Sealing, Labeling, Packaging

- Input ingredients

- non-alcoholic beverages, fruit-based drinks, vegetable-based drinks, water-based drinks, juices, smoothies, concentrates, ingredients with seeds, herbs, pulp, fibers

- Output ingredients

- pasteurized beverages, shelf-stable drinks, microbiologically safe beverages, nutrient-retained drinks

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Temperature range

- Up to 98°C

- High heating temperature

- Up to 125°C

- UHT temperature

- Up to 145°C

- Flow rate for plate heat exchangers

- 200 – 120, 000 l/h

- Flow rate for tubular heat exchangers

- 200 – 70, 000 l/h

- Heat recovery for plate heat exchangers

- Up to 95%

- Heat recovery for tubular heat exchangers

- Up to 92%

- Dual stream pasteurizer technology flow range

- 20% to 100% of maximum speed

- Automation

- Full automation and PU control

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- Up to 95% heat recovery

- Changeover time

- Fast switchover with minimal product loss

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Size and Shape

- Various

- Particle Handling

- Pulp/Seeds/Herbs

- Footprint

- Varies by customization

- Control panel type

- PLC / SCADA / HMI

- Integration possibilities

- Upstream functionality integration

- Application flexibility

- Hot filling / Cold aseptic filling / Ultra clean filling

- Batch size capability

- Small to large batch sizes

- Energy recovery options

- Heat pump technology / 95% heat recovery

- Switching capability

- Rapid product switching

- Heat exchange design

- Patented tubular heat exchange inlets