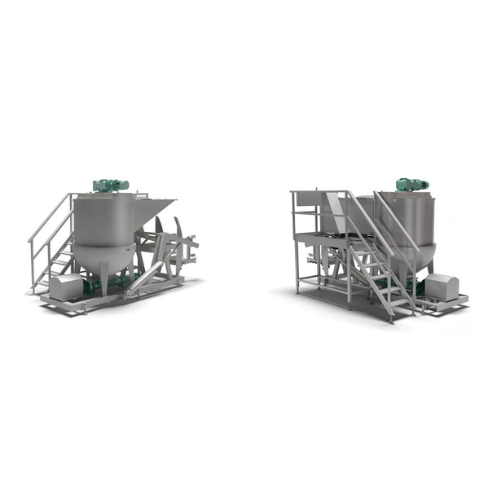

Crusher system for frozen juice processing

Effortlessly process frozen juices and concentrates by efficiently crushing, melting, and emptying drum contents into a seamlessly flowing production line.

Processes and Empties Frozen Juice Drums

The Crusher System from Bucher Unipektin provides an exceptional solution for processing frozen juices and concentrates, uniquely designed to maintain product quality through efficient crushing and melting. This system operates using a stainless-steel helical cutting blade mechanism to crush frozen contents from open-top drums, which are pneumatically clamped, lifted, and tilted to ensure efficient emptying.

Ideal for the food and beverage industry, the system excels in preparing orange juice concentrate, apple juice concentrate, and mixed fruit beverage bases. With a processing capacity of 40 drums per hour when crushing and melting, and up to 60 drums per hour when simply crushing and pumping, this equipment supports high-capacity operations.

Automated with a PLC for process control, it integrates seamlessly into existing production lines. The system also includes a screw pump to discharge the final product and a steam chamber to optionally melt the crushed product, enhancing pumping ease and preventing larger frozen block formation. Built from durable stainless steel, it ensures corrosion resistance and longevity. The integrated CIP spray cleaning system minimizes downtime and ensures hygiene standards are maintained. Additionally, the Crusher System is adaptable with components such as configurable drum handling and safety features, supporting customized engineering demands.

Benefits

- Increases production efficiency by handling up to 60 drums per hour.

- Preserves product quality and flavor through controlled melting and emptying.

- Enhances safety with pneumatic lifting and magnetic safety sensors.

- Reduces cleaning time and contamination risk with the CIP spray cleaning system.

- Minimizes manual intervention with fully automated PLC-controlled processes.

- Applications

- Juice concentrates, Frozen juices, Beverages

- End products

- Ready-to-drink juice bottles, Juice blend concentrates, Apple juice concentrate, Smoothie bases, Mixed fruit beverages, Orange juice concentrate, Frozen juice packs

- Steps before

- Loading, Transporting, Clamping

- Steps after

- Melting, Pumping, Discharging

- Input ingredients

- frozen fresh juice, juice concentrate, open top drums, cylindrical drums, conical drums

- Output ingredients

- crushed frozen product, melted product, juice flakes, liquid juice for further processing

- Market info

- Bucher Unipektin is known for producing advanced equipment and systems for the food and beverage industry, specializing in juice processing and filtration technologies with a reputation for innovative solutions and reliable, high-quality products.

- Processing capacity

- Crushed and melted

- Processing capacity

- Crushed and pumped

- Type of drums

- Open-top cylindrical and conical

- Capacity of the drums

- 200/250 L

- Steam chamber connection

- Female thread G 1 1/4"

- CIP connection

- Female thread G 3/4"

- Pneumatic connection

- Quick connector Ø10

- Crusher motor power

- 3 kW

- Pump power

- 11 kW

- Weight

- 2000 kg

- Working mechanism

- Helical cutting blades

- Integrated steps

- Crushing, melting, pumping

- CIP principles

- CIP spray cleaning system

- Batch vs. continuous operation

- Batch

- Automation level

- PLC-controlled

- Machine Footprint

- Not specified

- Drum Size

- 200/250 L

- Discharge Method

- Screw pump

- Structure Material

- Stainless steel

- Shape

- Cylindrical and conical open-top drums

- Weight

- 2000 kg

- Control panel type

- PLC for process control

- Discharge method

- Screw pump

- Cleaning method

- CIP spray cleaning system

- Material

- Stainless steel construction

- Safety features

- Pneumatic active safety system, Magnetic safety sensors