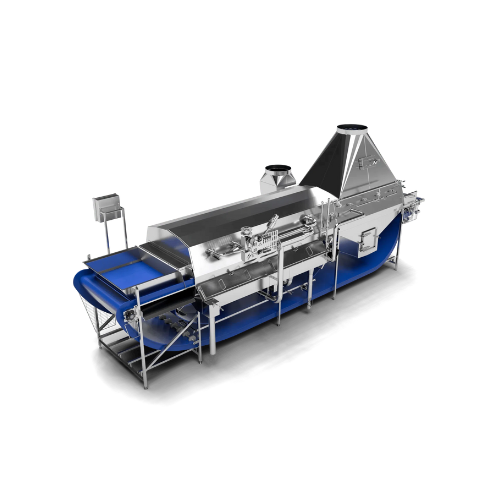

Evaporative blancher for fruits and vegetables

Achieve significant water savings and reduce wastewater generation in your food processing line with a system that integrates efficient blanching and cooling through innovative evaporative technology.

Blanches and Cools Diverse Food Products Efficiently

The BAC Blancher from Cabinplant is an engineered-to-order solution for food processors and industrial food manufacturers who face challenges with traditional blanching and cooling. This equipment stands out by utilizing evaporative air cooling to minimize water use, significantly reducing water consumption by up to 75% and wastewater by approximately 60%. It efficiently processes a range of products—from fish fillets and shrimp to vegetables like green beans and fruits—and is designed for continuous, automated operations. With a capacity ranging from 2 to 30 tons per hour, the BAC Blancher integrates smoothly into your production line, offering adjustable product discharge temperatures. It’s configured for easy integration and offers additional cooling via an optional water-cooling segment connected to a Baudelot chiller, achieving product temperatures as low as 10°C. Constructed with a hygienic design to facilitate effective cleaning, the BAC Blancher also offers flexibility with regard to blanching time and temperature, ensuring uniform processing across various industry applications.

Benefits

- Cuts water consumption by 75% for significant cost savings.

- Minimizes wastewater generation by approximately 60%, aiding environmental compliance.

- Ensures high product quality with low risk of contamination through hygienic design.

- Maintains high operational yields with uniform blanching and cooling.

- Offers flexible processing conditions, adjustable to various product requirements.

- Applications

- Seafood, Dairy food, Berries, Convenience food, Pet food, Meat, Fruits, Vegetables, Poultry, Fish

- End products

- Blueberries, Cheese cubes, Pet treats, Apple slices, Pork tenderloin, Beef strips, Pet kibble, Pear slices, Chicken breast, Shrimp, Peas, Green beans, Strawberries, Ready-to-eat meals, Yogurt, Fish fillets, Chicken wings, Carrots

- Steps before

- Washing, Sorting, Preparation

- Steps after

- Cooling, Packaging

- Input ingredients

- fish, seafood, meat, poultry, vegetables, berries, dairy food, convenience food, pet food

- Output ingredients

- blanched fish, blanched seafood, blanched meat, blanched poultry, blanched vegetables, blanched berries, blanched dairy food, blanched convenience food, blanched pet food

- Market info

- Cabinplant is known for designing and manufacturing tailored processing solutions for the food industry, specializing in fish, seafood, fruits, and vegetables. They are reputed for their innovative technology and efficiency in delivering customer-specific engineered-to-order equipment.

- Nominal Capacity for Green Pears

- 6, 000–16, 000 Kg/h

- Overall Length

- 8–18 m

- Steam Consumption max

- 1, 100–2, 600 Kg/h

- Water Consumption max

- 0-6 m³/h

- Nominal Power Consumption

- 18/36–48/96 kW

- Cooling Temperature

- 20–30˚C

- Product Temperature after Additional Cooling

- ≈10°C

- Capacity

- 2 to 30 t/h

- Cooling mechanism

- Evaporative/Chilled water

- Refrigerant

- Air

- Water conservation

- Up to 75% less water

- Wastewater generation

- Approximately 60% less

- Product discharge temperature range

- 20-30˚C

- Integration with Baudelot chiller

- Optional for temperatures below 20-25°C

- Temperature reduction enhancement

- Recirculated chilled water

- Cleaning method

- Hygienic design

- Automation level

- Manual / Optional enhancements

- Operation type

- Continuous

- Flexibility in blanching time and temperature

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Varies

- Container size

- 2 to 30 t/h

- Machine footprint

- Varies with model (e.g., BAC 6

- Overall Length

- 8–14 m

- Control panel type

- Customizable

- Customer-adapted design

- Yes, tailored solutions

- Hygienic design

- Easy cleaning

- Integration possibilities

- Blanching and cooling integration

- Cooling method

- Evaporative air cooling

- Optional water-cooling segment

- Available

- Capacity range

- 2 to 30 t/h