Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designed for optimal sanitization and seamless integration in packaging lines, ensuring the quality and safety of your liquid and slurry products.

Fills and Seals Aseptic Bag in Box

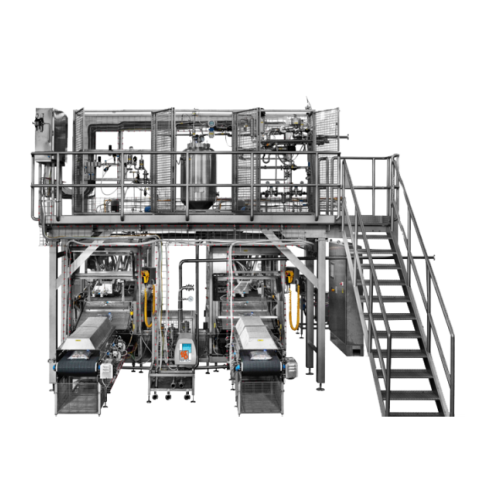

The N.E.S Aseptic Filler from FBR Elpo is engineered to meet the strict requirements of aseptic filling for the dairy, fruit, and beverage industries. This advanced machine ensures sterility while providing high-speed filling and sealing for various products, including juices, purees, and tomato and fruit concentrates. The system operates on a synchronized process, seamlessly integrating filling, sealing, carton formation, and transfer operations. The double-headed version efficiently fills up to 900 bags per hour, supporting continuous, high-speed production.

Designed with energy efficiency in mind, it requires minimal steam and compressed air, optimizing resource use without compromising performance. Built from corrosion-resistant materials, the machine is suitable for handling acidic and viscous products, ensuring longevity and reliability. The N.E.S Aseptic Filler also features an intuitive control interface, making it easy to integrate into existing production lines, promoting seamless automation and process monitoring.

Equipped with a clean-in-place (CIP) system, it simplifies maintenance and reduces downtime, while rigorous compliance with food safety standards ensures that each operation upholds product quality and safety. The machine is highly customizable, offering various configurations to meet specific production needs and industry requirements, backed by dedicated engineering support.

Benefits

- Enhances productivity with a filling capacity of up to 900 bags per hour.

- Ensures product integrity and safety with aseptic processing capabilities.

- Minimizes operational costs through efficient steam and air consumption.

- Integrates seamlessly into existing lines, reducing installation time.

- Simplifies maintenance with a built-in clean-in-place (CIP) system.

- Applications

- Diced fruit, Tomato concentrates, Tomato pulp, Purees, Citrus juices, Fruit concentrates, Juices, Pizza sauce, Dairy

- End products

- Pizza topping sauce, Milk, Apple juice, Orange concentrate, Diced peaches, Orange juice, Tomato paste, Mango puree, Marinara sauce, Lemon concentrate, Yogurt, Strawberry puree, Diced pineapple, Tomato sauce

- Steps before

- Carton formation, Product sanitization, Aseptic product feeding

- Steps after

- Sealing, Packing, Storage

- Input ingredients

- juices, purees, fruit concentrates, tomato concentrates, citrus juices, diced fruit, tomato pulp, pizza sauce

- Output ingredients

- webbed bags

- Market info

- FBR ELPO is known for its expertise in manufacturing industrial equipment, specializing in engineered-to-order solutions for food and beverage processing, particularly in thermal processing and aseptic technology, and holds a strong reputation for innovation and reliability in the market.

- Operating speed

- Up to 450 s.p.h. / Up to 900 s.p.h.

- Height

- 2, 600 mm

- Width

- 1, 300 mm / 3, 800 mm

- Length

- 3, 700 mm

- Installed power

- 8 Kw / 15 Kw

- Steam Consumption

- 20 Kg/h 6 bar / 40 Kg/h 6 bar

- Compressed air consumption

- 180 Nm³/h 8 bar / 360 Nm³/h 8 bar

- Bag size

- 3-5-10-20 liter webbed bags

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Changeover time

- Not specified

- Cleanability

- Easy clean design for aseptic operations

- Corrosive resistance (e.g. acids)

- Anti-corrosive materials for tomato and citrus juices

- Machine Height

- 2, 600 mm

- Machine Width

- 1, 300 mm (AS-I-30-WEB) / 3, 800 mm (AS-II-30-WEB)

- Machine Length

- 3, 700 mm

- Machine Footprint

- Specific dimensions joined per version

- Bag Size Compatibility

- 3-5-10-20 liter webbed bags

- Operating Speed

- Up to 450 s.p.h. (AS-I-30-WEB) / Up to 900 s.p.h. (AS-II-30-WEB)

- Coupling Capability

- Entire line for carton formation, transfer, filling, and sealing

- Control panel type

- PLC/SCADA Interface

- Integration possibilities

- Compatible with carton formation, transfer, filling, and sealing lines

- Aseptic product feeding tank

- Optional installation