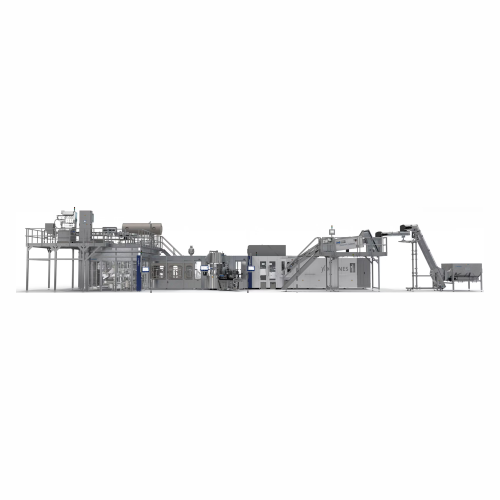

High-performance stretch blow moulding and labelling system

Maximize space and efficiency with this compact system that consolidates blow moulding, labelling, filling, and capping in one streamlined operation, ensuring continuous high-speed output while optimizing energy use and reducing operational footprints.

Blows, Labels, Fills, and Caps Beverage Containers

The ErgoBloc L from Krones is an integrated solution combining stretch blow moulding, labelling, filling, and capping into one compact unit. Designed to transform your production line, this system excels in optimizing space with its block-synchronised design, reducing transport distances, and accommodating up to 100,000 containers per hour. Ideal for beverage manufacturers and PET bottle producers, it handles a variety of liquid products, from non-carbonated to carbonated beverages, including soft drinks, juices, and plant-based milk.

Powered by advanced infrared heating technology, it ensures precise control and minimal energy consumption, achieving up to 11% reduced energy usage compared to previous models. The Air Wizard Triple further cuts compressed air use by up to 20%, enhancing overall efficiency. Automating four core processes, the ErgoBloc L requires just one operator, guaranteeing seamless operation and shorter changeover times.

The system supports diverse container types—ranging from still water bottles to protein shake bottles—crafted with up to 100% recycled PET. Its fully-electronic PFR filling valve allows for infinitely variable control, while features like the “No bottle – no label” function reduce glue and label waste. Designed for extended operation, it integrates seamlessly into high-speed, automated production environments, proving indispensable in the beverage, food, and packaging industries.

Benefits

- Maximizes production efficiency by handling up to 100,000 containers per hour with minimal manpower.

- Saves up to 70% of floor space compared to traditional setups, optimizing facility layout.

- Reduces energy consumption through optimized infrared heating and Air Wizard Triple systems.

- Minimizes material waste with precise labelling and capping technology.

- Supports sustainable production with 100% recycled PET processing capabilities.

- Applications

- Carbonated beverages, Water, Alternative proteins, Milk and milk-based drinks, Non-carbonated beverages, Spirits, Juice, Soft drinks, Plant-based milk

- End products

- Craft beer cans, Almond milk bottles, Rye whiskey bottles, Cola bottles, Sparkling water bottles, Orange soda cans, Soy milk packages, Sports drink bottles, Oat milk cartons, Yogurt drink containers, Protein shake bottles, Apple juice cartons, Still water bottles, Flavored water pouches, Kombucha bottles

- Steps before

- Preform production, Bottle design, Container production, Material selection, Injection moulding, Material-saving packaging design

- Steps after

- Packing, Label application, Cap sorting, Recycling, Logistics, Distribution

- Input ingredients

- non-carbonated beverages, carbonated beverages, cylindrical PET containers, square PET containers, standard containers, lightweight containers, containers with volumes from 0.25 to 3.5 litres, containers made of up to 100 percent rPET, preforms

- Output ingredients

- blown PET containers, labelled PET containers, filled PET containers, capped PET containers, self-adhesive labels, reel-fed plastic labels, flat caps, sports caps

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Functions

- Stretch blow moulding, labelling, filling and capping

- Output

- Up to 100, 000 containers per hour

- Processing range

- Non-carbonated and carbonated beverages

- Container type

- Cylindrical and square PET containers

- Container volume

- 0.25 to 3.5 litres

- Container material

- Up to 100% rPET

- Label type

- Self-adhesive labels and reel-fed plastic labels

- Cap type

- Flat caps and sports caps

- Heating technology

- Infrared

- Station output

- Up to 2, 750 containers per hour per blowing station

- Labelling speed

- Up to 50, 000 containers per hour

- Compressed air consumption

- Up to 20% less due to Air Wizard Triple

- Energy consumption

- Up to 11% reduced in infrared oven

- Filling valve

- Fully-electronic PFR with infinitely variable control

- Error detection

- "No bottle – no label" function

- Glue consumption

- Minimal (Contiroll TS system)

- Automation

- Handled by one operator

- Footprint

- Up to 70% less space required

- Integrated Steps

- Stretch blow moulding, labelling, filling, capping

- Output per Hour

- Up to 100, 000 containers

- Space Utilization

- 30% less space required

- Energy Efficiency

- Infrared heating technology, Air Wizard Triple

- Operator Requirement

- One operator for the entire process

- Container Compatibility

- Cylindrical and square PET, 0.25 to 3.5 liters

- Labeling Capability

- Self-adhesive labels, reel-fed plastic labels

- Cap Type

- Flat caps, sports caps

- Compressed Air Usage

- 20% less with Air Wizard Triple

- Changeover Efficiency

- "Skip-and-Run" function

- Cleaning Method

- Minimal glue consumption (Contiroll TS)

- Handling System

- Neck-handling system

- Filling Valve

- Fully-electronic PFR with variable control

- Cap Sorting

- Close to ground, maximum speed

- Environmental Classification

- Enviro-classified for energy efficiency

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container shape

- Cylindrical / Square

- Cap type

- Flat / Sports

- Machine Footprint

- Requires 30% less space than conventional systems

- Compact Footprint

- 70% less space requirement compared to separate machines

- Output Capacity

- Up to 100, 000 containers per hour

- Container Size Range

- 0.25 to 3.5 litres

- Container Material

- PET, up to 100% rPET

- Container Shape

- Cylindrical and square PET containers

- Label Type

- Self-adhesive labels and reel-fed plastic labels

- Cap Type

- Flat caps and sports caps

- Blowing Station Output

- Up to 2, 750 containers per hour per station

- Control panel type

- PLC / HMI

- Integration possibilities

- One operator for complete process

- Compact design

- 70% less space requirement

- Customization of labels

- Self-adhesive and reel-fed plastic labels

- Cap types

- Flat caps and sports caps